- Mar 2, 2015

- 6,822

- 5,858

- 203

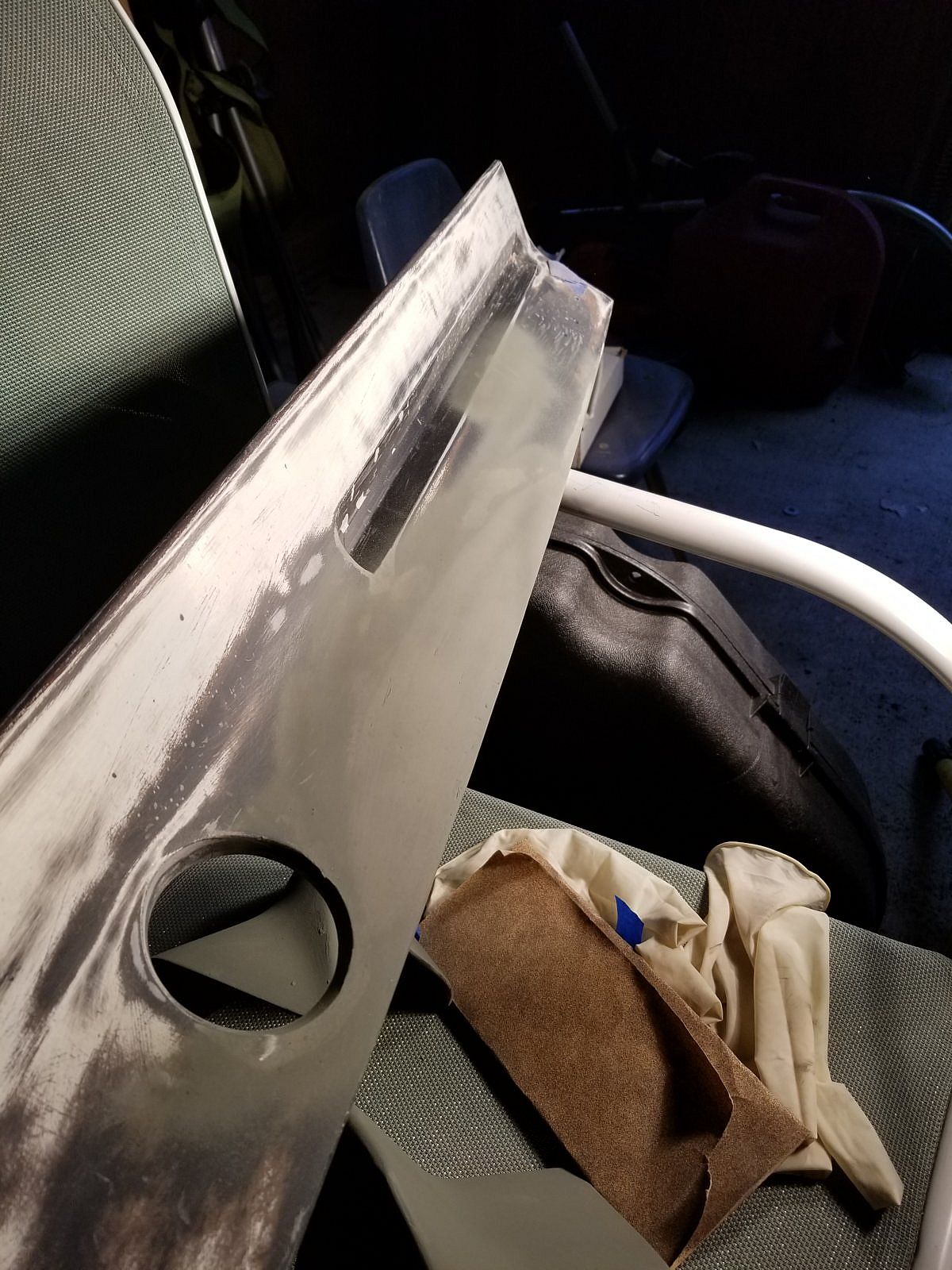

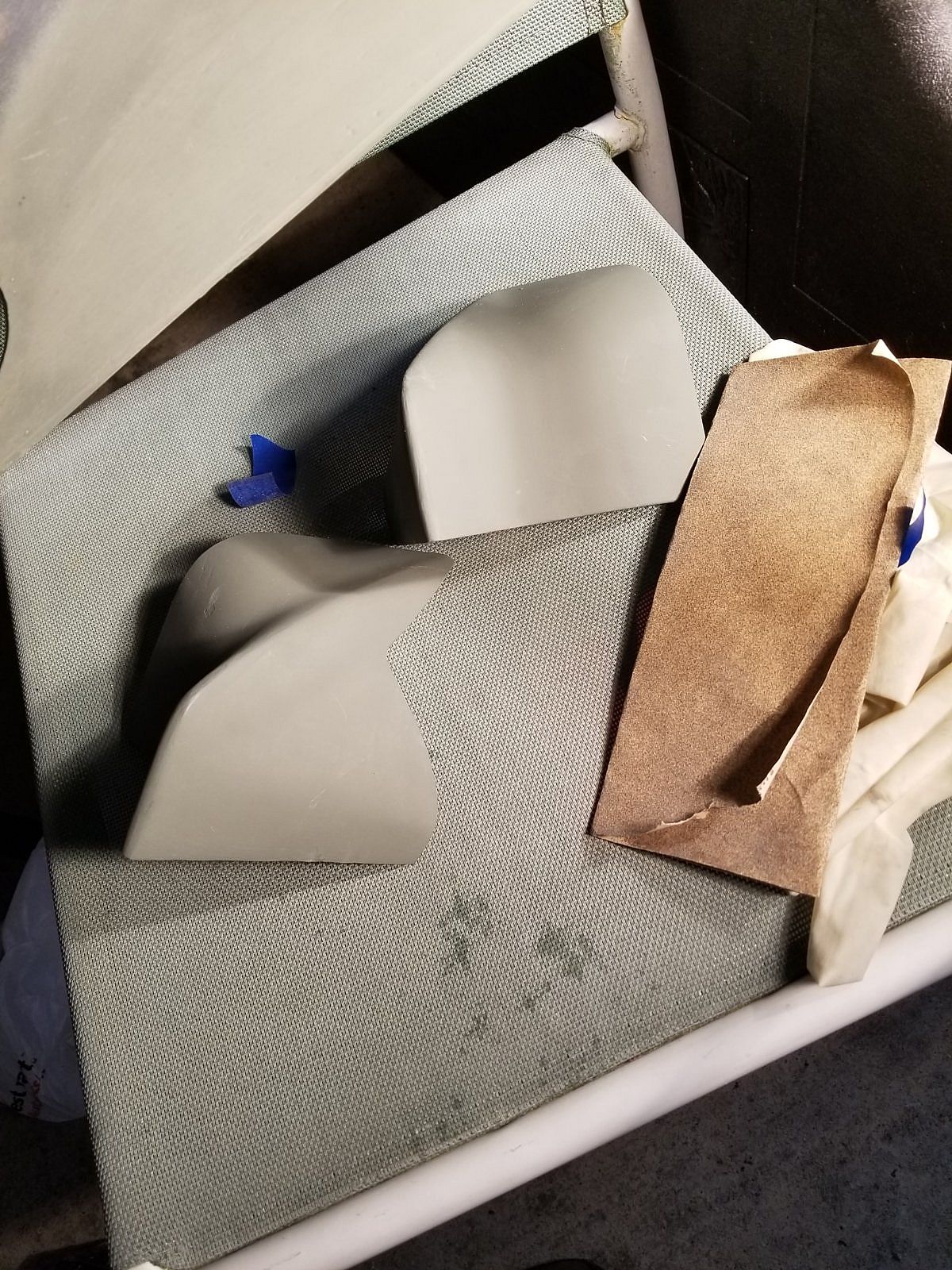

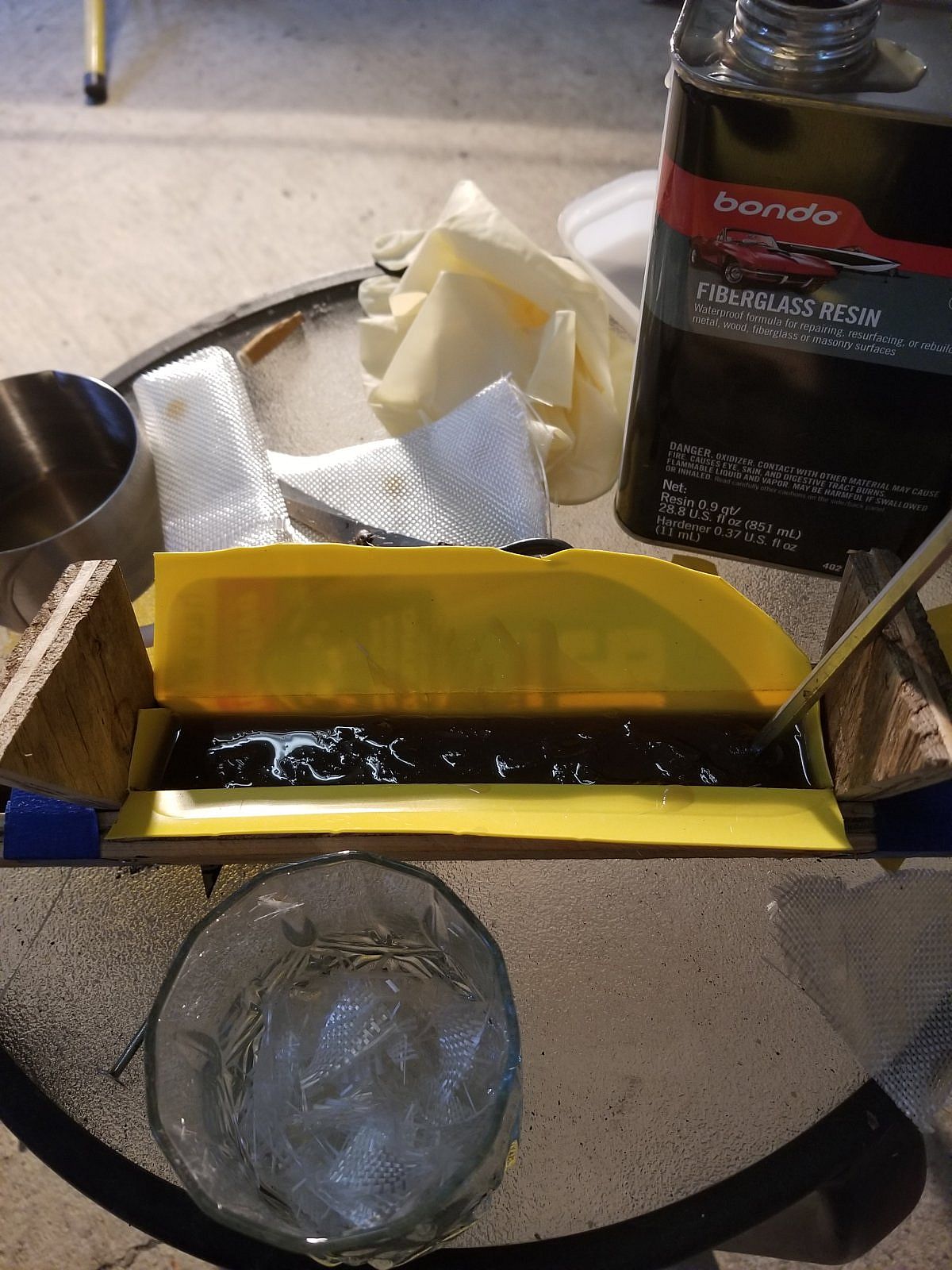

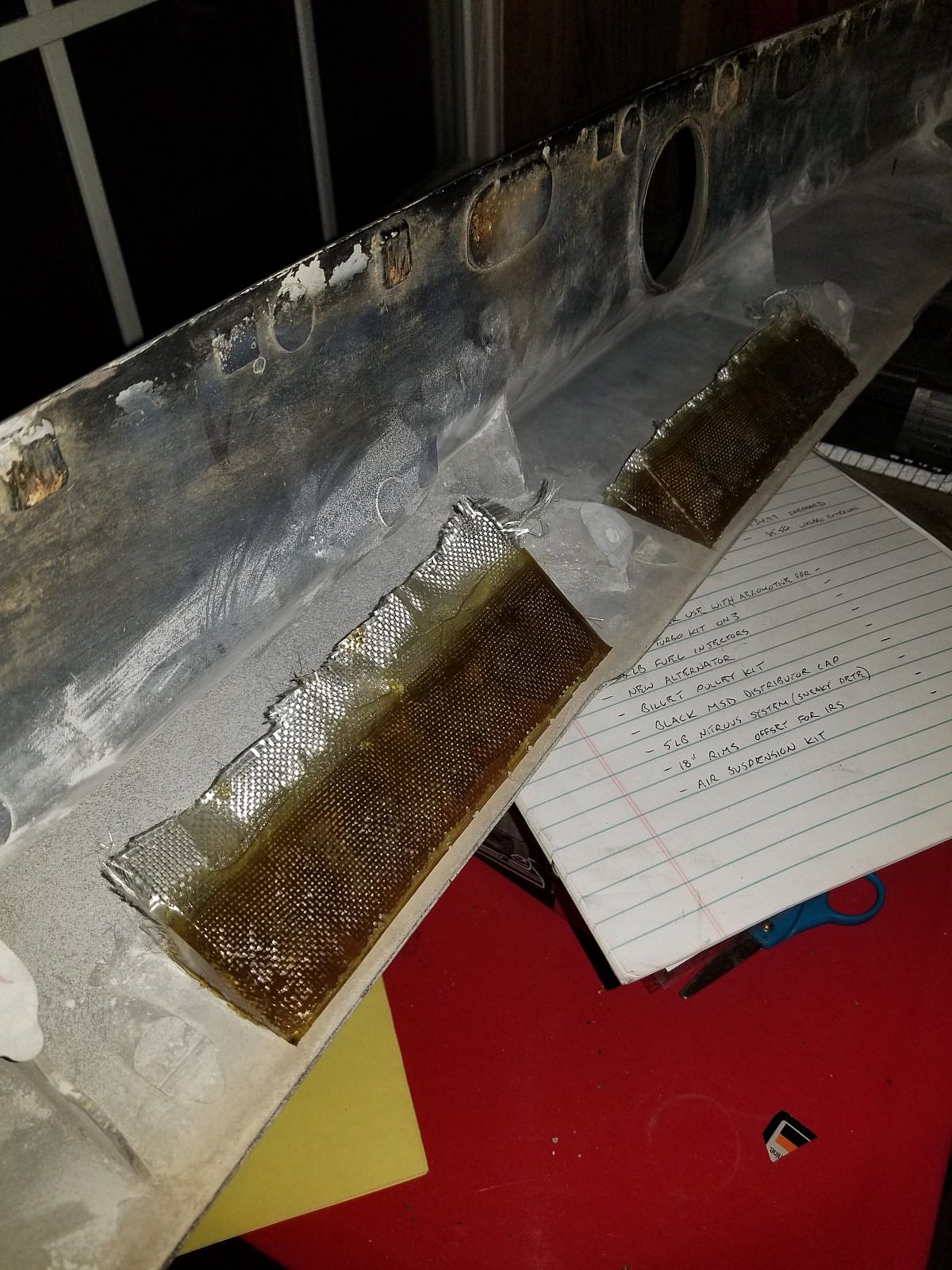

Hey Scott show me a picture or two of what you’re talking about in the firment issues.

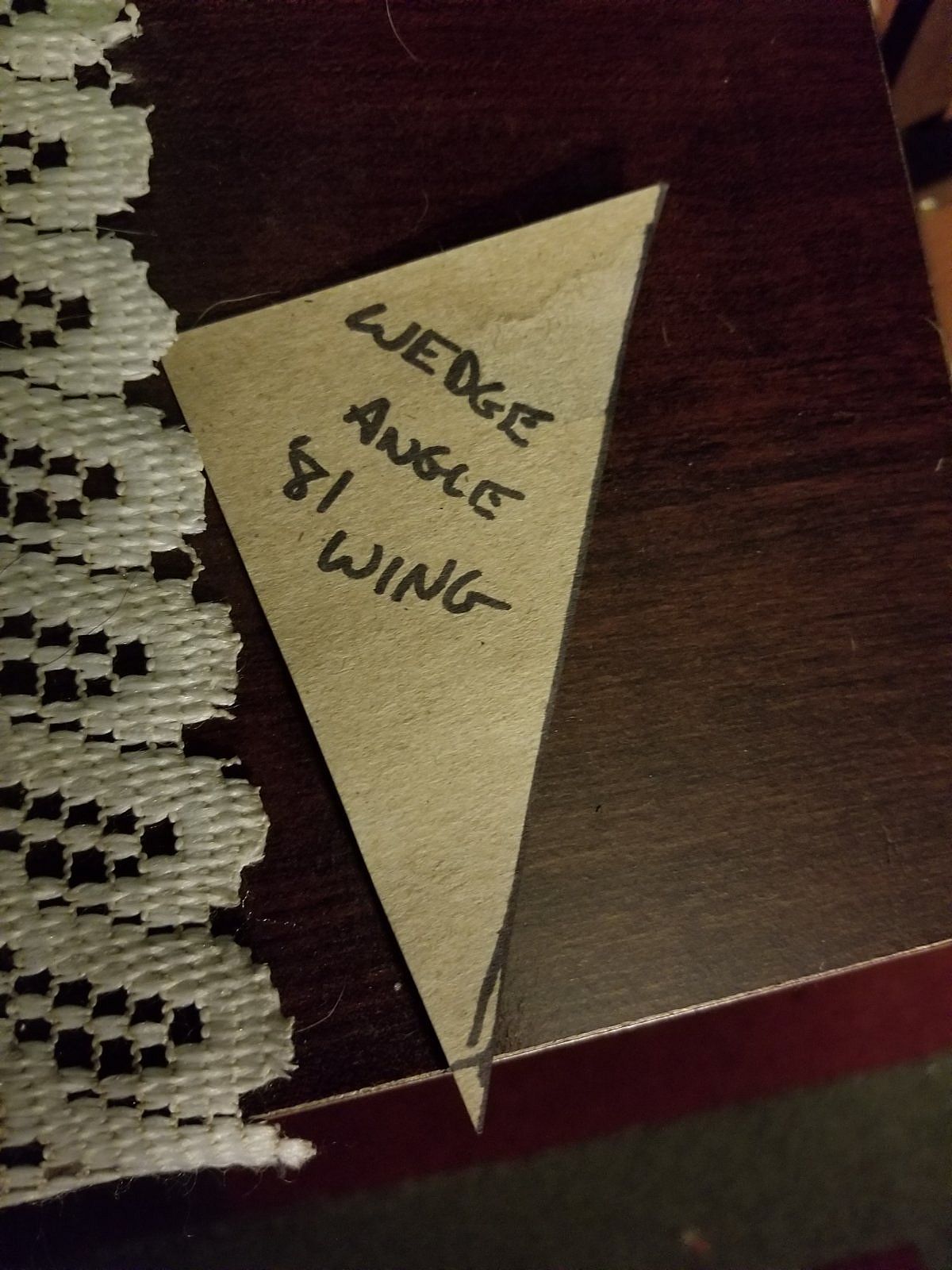

The paper template is exactly the right thing to do. When I go to widen Booger’s quarters I will do that with each piece. That keeps the symmetry correct between sides.

I'll take some pics tomorrow.