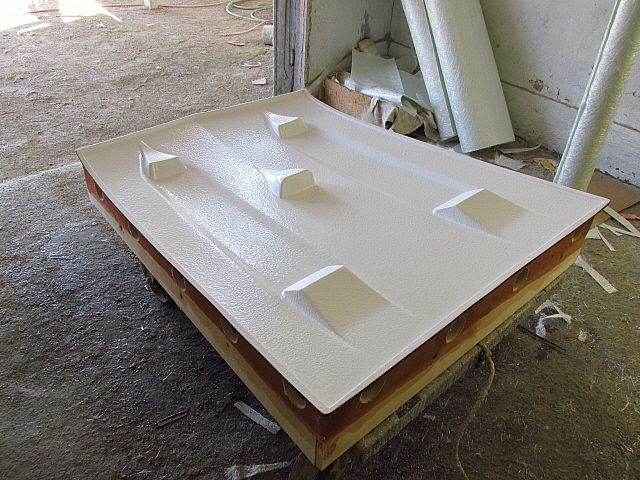

I gel coated the under brace mold this morning .

I then cut 3 sheets of 2oz mat and started laying it up .

The hood hinge area will have a 12 inch x 1 1/2 inch

x 3/16 plate that I embedded into the under brace ,It will be drilled and threaded . The original hood springs will be able to be used .

Tomorrow i will trim out the under brace and see what i have to do to shorten it to fit the short hood ,it will have to be cut in front of the hood latch because both the long and the short hood latch in the same location.

The latch plate will be pop riveted inside the under brace and the factory catch will be used .

I then cut 3 sheets of 2oz mat and started laying it up .

The hood hinge area will have a 12 inch x 1 1/2 inch

x 3/16 plate that I embedded into the under brace ,It will be drilled and threaded . The original hood springs will be able to be used .

Tomorrow i will trim out the under brace and see what i have to do to shorten it to fit the short hood ,it will have to be cut in front of the hood latch because both the long and the short hood latch in the same location.

The latch plate will be pop riveted inside the under brace and the factory catch will be used .

Isn't it purdy ? I just have to make the under brace mold .

Isn't it purdy ? I just have to make the under brace mold .

I don't have a clue why the pic is distorted ,stupid camera

I don't have a clue why the pic is distorted ,stupid camera