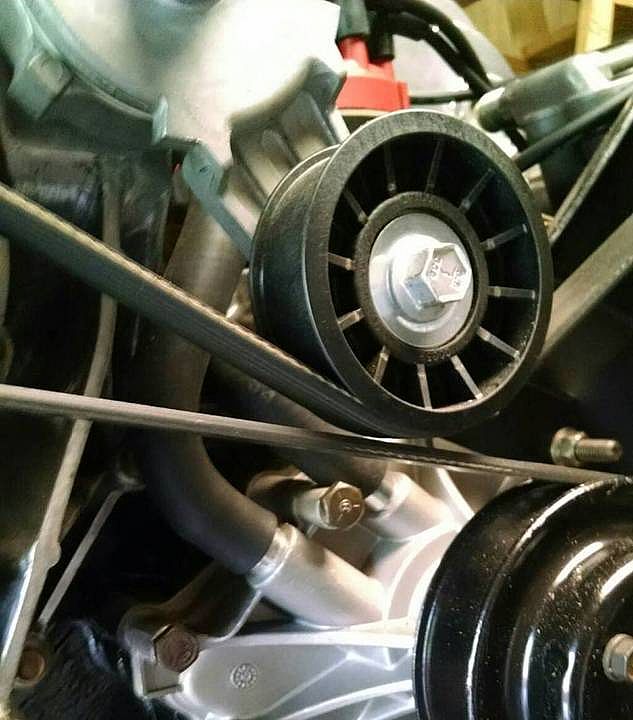

I've seen about 100 threads about it but nothing clearly defined. Is there a part number I can use for a 5.0 serpentine belt without the smog pump? I have a 77.5 belt on it now and this is my 2nd belt. I'm thinking this belt is not the quite the right one because I'm getting belt shavings showing up on my airbox and after about 2 months or so, the belt breaks.

Thanks!

Thanks!