Well I'm back.

On another thread I stated that I had lost my motivation to work on the car due to lack of work. In truth December was a slow month, but it did manage to actually turn around at the end, and gave me the funds, and peace of mind to actually consider attempting some progress on the GM. In the end, I'm still gonna have to find a real job,..but this being the end of the year, the likelihood that anybody will do anything is so remote that it's best to just wait till the new year to resume the search.

In light of that,.... I "endeavored to persevere"

First,.... The tools of the trade.

On the previous reply I said that my grinders had both died. I use two 4.5" angle grinders, and keep one for cutting, and one for grinding. Before they did die however, I told the wife that I needed two new ones, and that they were cheap enough that one of the kids could buy me one for Christmas. Since I had to have one at least one however, I went to Sears and bought one of theirs so I could make due.

Come Christmas,...turns out that the Senior Airman that is #1 son decided that I needed a really good one. So he buys me a Milwaukee 7 amp rated piece.

I'm back to being a grindin' fool.

#2 works at Brookstone. PT. He bought me this car washing kit that comes in a plastic carrying case. Just the thing when the Monster finally starts seeing the road.

The wife buys me these HF rolly things for under the tires:

And because "it was such a good deal", she buys me a replacement EZ up for the poor, battered 10 footer unit I've been working under for the last couple of years. Only this one is a 10 x 20'

Now in light of the fact that most really good 10 x 20's cost over 500.00, and given that I haven't had any decent income for the last few months, I told her to take that thing back. She promptly told me to shut up. That the thing didn't cost anywhere near what I thought it did. She shows me a pic of the thing, and divulges that it only cost 170.

It's far from an "EZ up" but it'll do to keep the sun off my ass. How long it lasts will be a wait and see thing, but for now,...I'm blessed.

So now I gotta go down there and do something.

The piece of aluminum that will make up the chin spoiler/splitter is standing in the corner, only needing cutting, welding, bending,and grinding to be considered built. (Yeah,..only)

But again, I got all this new junk, so it should be a piece of cake,....(not that I haven't had enough pieces of cake these last few days).

This is how this goes then:

I'm making the thing out of two separate pieces. The shroud that holds the oil, and transmission cooler being the centerpiece between the two sides. I scribed the lines, marked the angles, and cut the pieces out w/ a hand held band saw.

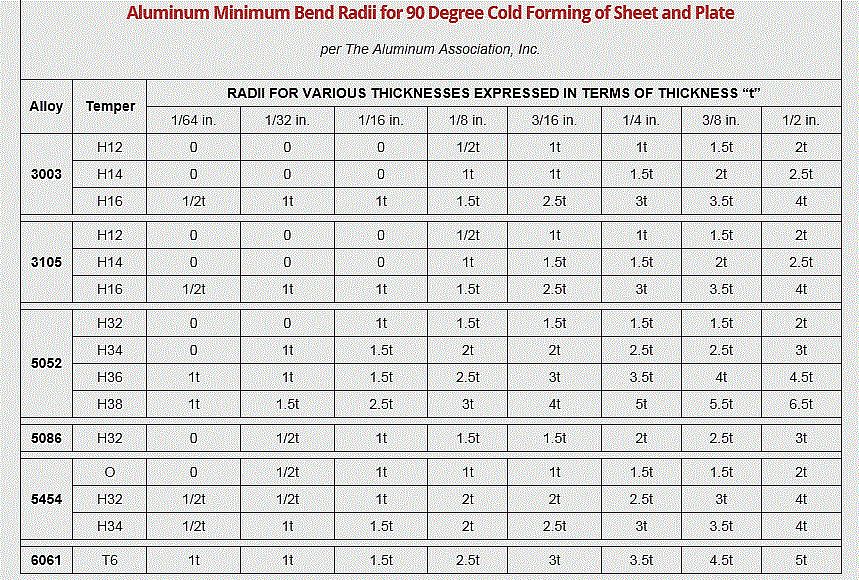

At the end of each side the thing angles up to almost 90 degrees to follow the down angle of the fender. This is 3003 alloy aluminum, the same stuff I used on the trunk that makes up the G tail in back. It's bendable. Unlike 6061 alloy which is way more rigid, this stuff wont crack when subjected to the stress of getting bent.

Nonetheless, it was still 1/4" thick. It's not like I'm gonna bend the thing over my knee or anything. So I flipped the thing over and cut a relief into the back side so I was only trying to bend 1/8" instead

After that, it bends by hand in a vise.

Once at the angle I wanted it to be, I broke out the spool gun and converted the welder over to weld aluminum.

Considering that this was the first time I've ever used a spool gun, (and ever attempted to weld aluminum) it was easy in retrospect. The feed was a little too fast, but I pulsed the thing anyway, the plan is to grind that weld smooth anyway.

It's gonna take some serious staring at the thing to decide how I want to mount it, but there will definitely be at least a couple of clevises on the outermost part, The inside edge will bolt to the lower radiator saddle, and there'll be a tab welded onto each side of the cooling shroud to support the thing. I want it to be almost parallel to the road surface when it's mounted.

but since it isn't this is where we stop.

I did manage to get the holes plugged and sanded down on the roof. I rattle canned some etching primer on the roof until today, This is what I got after a round with the long board

I'm just gonna assume that you can see all the low spots in the pic.

Hail damage. Not bad, but enough to show that the thing has been exposed to it before. I was focusing on getting the 15 or so holes that the roof trim used to go through fixed, that I ignored the rest thinking it was all good.

No said the finger. Not good at all.

You cant feel these low spots. This is one case where I'm unsure if the proper solution to fix this will be the subsequent layers of high build primer that have yet to be applied.

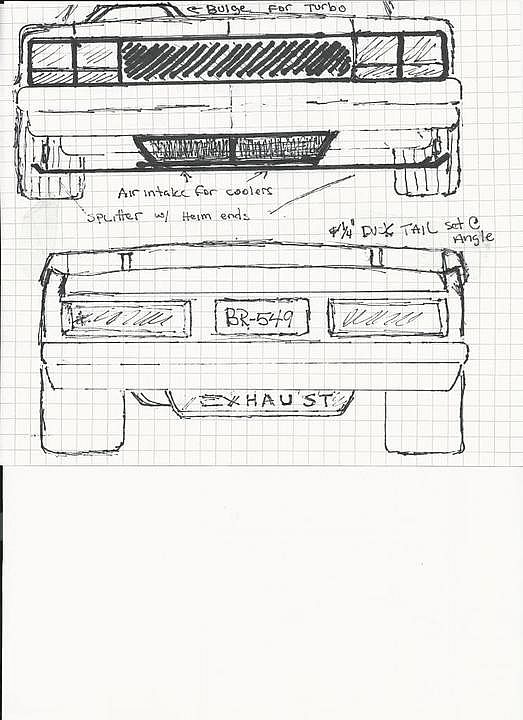

After I get the front spoiler thing fixed, I've got the passenger side G gill to finish, and get spot primed. the last point of contention is the internal doubt concerning the hood scoops.

The original hand sketch had a single blister on that side of the hood where the fitting on the turbo sticks through the hood. I have the material build that blister. This time it'll be better than the cake pan that was my first attempt at it.

I just don't know. I kinda like the twin scoop thing, but one way or the other, I have to cut a hole in the hood for that fitting to poke through. One way, the engine/turbo will be exposed to water and air (unless I close the hood scoop),....and I'm thinking what would be the point of a hood scoop that doesn't do anything? The other way (with the blister) there is no false scoop sitting there, just a big assed bump. leaving somebody to wonder why it is, and what is under there.

The scoops are made, the blister is not. There are 12 holes drilled in the hood that the scoops would've bolted through if I use them, but even that is looking like I'm gonna weld those scoops for the sake of making them permanent so they wont move around and mess up the paint later.

If I have to have a problem with the scoops,..its how thin the front edges are,....they're are almost a knife edge.

One way of the other I'm welding something to that hood.

No said the finger. Not good at all.

No said the finger. Not good at all.