I'm dense, would you reword that question please?Sounds good to me, I just want it to be smooth and not as noticeable. I was literally showing my wife the pictures of your POR15 and some videos on their site; and gave me the idea to just go ahead and do the jambs since when I get it painted I can just do the outside.

Debating on the gray or black now.

Have you repair/prepped metal were the pain got hot before or just replaced the panel?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Paint and Body Fox Body Painting 101

- Thread starter Davedacarpainter

- Start date

-

Sponsors (?)

I'm dense, would you reword that question please?

have you prepped a panel with fire damage, specifically fenders. The paint got hot enough it look like the top of cappuccino

Ahh! Yes I have worked on them. It's easier to work, believe it or not.

Problem is, it takes the tempering out of the metal (or tempers it improperly in reality).

If it burned hot by your frame rail, you might consider replacing it.

It will need to be tightened up though. Kind of like I'm having to do to my hood.

If it isn't warped bad, just grind off the old paint, etch it, primer it, etc.....

Problem is, it takes the tempering out of the metal (or tempers it improperly in reality).

If it burned hot by your frame rail, you might consider replacing it.

It will need to be tightened up though. Kind of like I'm having to do to my hood.

If it isn't warped bad, just grind off the old paint, etch it, primer it, etc.....

Make the bondo feel seamless. Use a rag or paper towel on your hand to run your hand over the surface to check the straightness of the repair.

You'll want to use the dry clean rag because the skin on your hand will have the tendencies to feel each surface differently when run directly over it. You'll feel issues in the repair when there may be none at all when using your bare hand.

It's best to finish out the filler repair with 150-180 grit before priming. The deeper the scratches you have, the more primer required to fill it. The more primer you use will have more solvents that escape allowing for more shrinkage of it.

I think I figured out my disconnect. I've been trying to get body filler and the feather edges smooth enough for primer without using glaze...

You gotta use a final glaze to get it to block out right?

Sorry, still learning

I think I figured out my disconnect. I've been trying to get body filler and the feather edges smooth enough for primer without using glaze...

You gotta use a final glaze to get it to block out right?

Sorry, still learning

Glaze isn't necessary if your bondo is pinhole free and it feels straight. It is easier to finish off the work though. You apply it in a very thin coat (hence "glaze"). It will fill pinholes and heavier scratches from the more aggressive sandpaper used to block the initial filling straight. So, it's generally not used for straightening.

Ok, so I'll just post a pic of what I'm dealing with. I wanna preface by saying this is not even close to something I'd paint over. This is just trying to get it so it don't bug me every time I see it till I actually start the body work. I plan to properly strip to metal and go from there, but I'm using this as a chance to learn.

So I'm the pic, I welded up the hole, ground, tapped it down, body filler, da sanded with 80, and primed with canned filler primer. This is where I start to get lost. Am I sanding the filler too much? I know I need to take it to 120 when I'm using proper materials. I know the canned primer is much thinner than the spray stuff so I dunno if that is the issue? This is where I thought glaze was needed but I'm not sure.

So I'm the pic, I welded up the hole, ground, tapped it down, body filler, da sanded with 80, and primed with canned filler primer. This is where I start to get lost. Am I sanding the filler too much? I know I need to take it to 120 when I'm using proper materials. I know the canned primer is much thinner than the spray stuff so I dunno if that is the issue? This is where I thought glaze was needed but I'm not sure.

Attachments

Ok, new pics to show more of what I'm dealing with. You can see the original paint, then coats of primer/sealer/ white paint. This will all come off when I do this proper.

Again, this is just for learning, not a final product.

I think , the steps would be to widen the sanded area , do a coat over the weld area to fill it in, knock it down, then do a skin coat over the whole area, then block that with 80-120-150, then a coat of primer??

Again, this is just for learning, not a final product.

I think , the steps would be to widen the sanded area , do a coat over the weld area to fill it in, knock it down, then do a skin coat over the whole area, then block that with 80-120-150, then a coat of primer??

Attachments

Pretty much.Ok, new pics to show more of what I'm dealing with. You can see the original paint, then coats of primer/sealer/ white paint. This will all come off when I do this proper.

Again, this is just for learning, not a final product.

I think , the steps would be to widen the sanded area , do a coat over the weld area to fill it in, knock it down, then do a skin coat over the whole area, then block that with 80-120-150, then a coat of primer??

Feather it a little further like you said. You may get away with just using glaze to fill that. It doesn't look bad at all.

If you use glaze, you won't need as harsh of a grit ofnsandpaper. 80 grit for the initial blocking, just to knock it down. Finish in 150 or 180 prior to primer.

If you ever want me to give you a call, just pm me and I'll tell you what I'd do. I can get across in a couple minutes talking what it would take 15 to type.

I'll 100% take you up on that. This has kinda been side tangent, so I'm gonna mess with it tonight for the sake of it, but then it's getting primed and ignored till I'm ready to strip all the paint off. I count at least 5 layers there and it's flaking off on the corners, so it's gotta go.Pretty much.

Feather it a little further like you said. You may get away with just using glaze to fill that. It doesn't look bad at all.

If you use glaze, you won't need as harsh of a grit ofnsandpaper. 80 grit for the initial blocking, just to knock it down. Finish in 150 or 180 prior to primer.

If you ever want me to give you a call, just pm me and I'll tell you what I'd do. I can get across in a couple minutes talking what it would take 15 to type.

But my goal is to start my 5 lug this weekend and this is only a deterrent.

liljoe07

5 Year Member

What do you use to get dried on buffing compound off? When my car was buffed after I had it painted, I found specs of dried compound in lots of places. Been a pain trying to remove it.

Denatured alcohol works pretty good.What do you use to get dried on buffing compound off? When my car was buffed after I had it painted, I found specs of dried compound in lots of places. Been a pain trying to remove it.

Btw, i never finished up with the bumper repair on this thread so.....

After i reprimered the bumper, i blocked it with 320. I then cleaned it up, sealed it, five coats of Kona blue and clearcoated it.

My primer, sealer and clearcoat all have flex additive. Check to see if your paint will have this additive in it, these bumpers are very flexible.

Anywho, pictures:

After i reprimered the bumper, i blocked it with 320. I then cleaned it up, sealed it, five coats of Kona blue and clearcoated it.

My primer, sealer and clearcoat all have flex additive. Check to see if your paint will have this additive in it, these bumpers are very flexible.

Anywho, pictures:

Another thing, i'm going to show how to shrink stretched metal in my blue car's build thread. I guess it would be a good idea to show how i do it here as well.

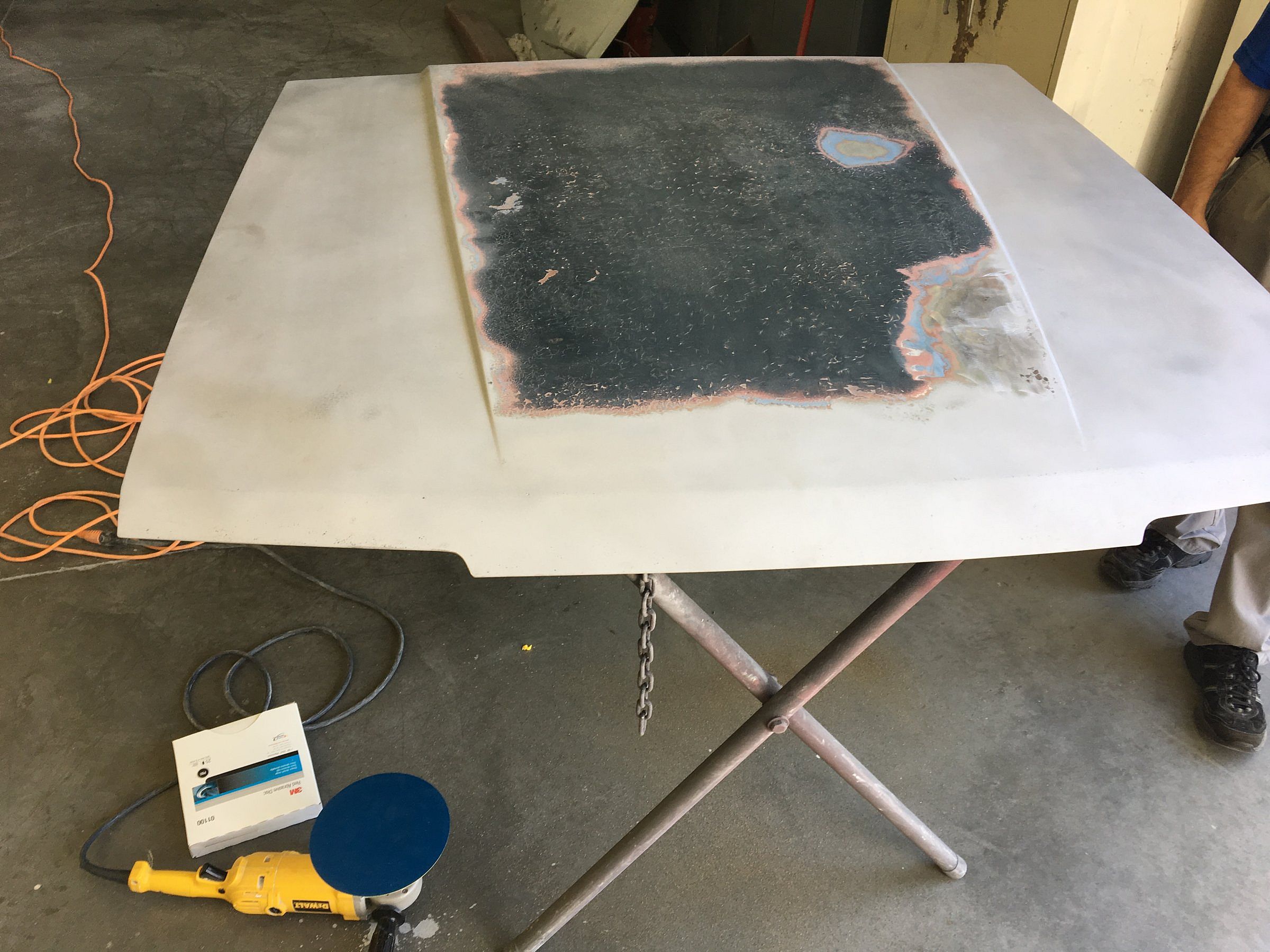

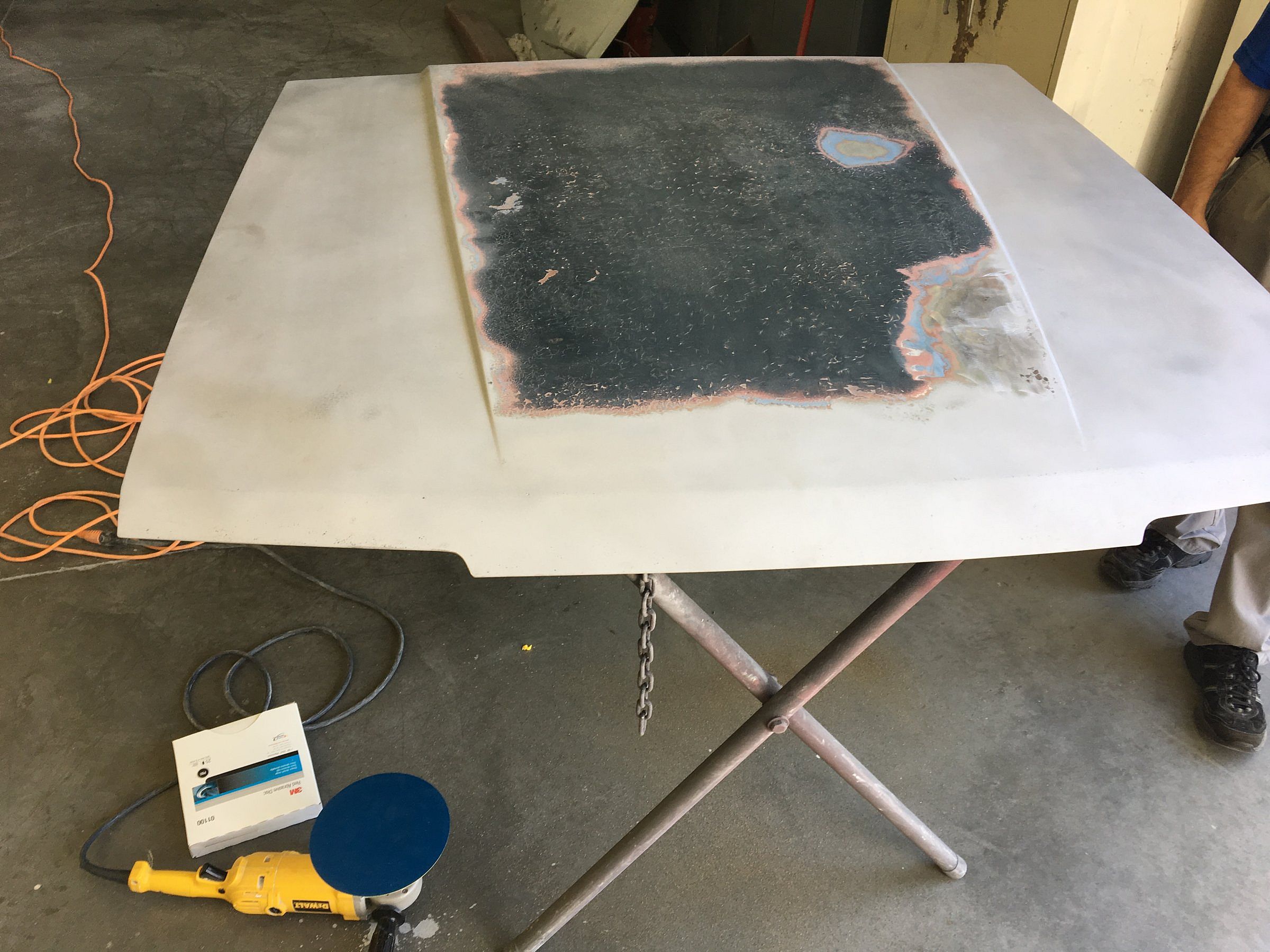

My test subject is the hood to my blue car that was a little rough in the first place, then i took it to my media blasters to have them clean the paint around the edges and the supports underneath.

Well, the blasters got in a hurry and just blasted the entire underneath side . This warped the hell out of the flat unsupported surface of the hood. Sandblasting creates a lot of heat on metal, thin surfaces like a hood skin should never be blasted with sand, use something like crushed walnut shells or soda blasting.

. This warped the hell out of the flat unsupported surface of the hood. Sandblasting creates a lot of heat on metal, thin surfaces like a hood skin should never be blasted with sand, use something like crushed walnut shells or soda blasting.

I'll get a picture of the tools i'm using and a couple of me working out one of the larger warps. You'll see in the pictures i'm posting that i've already been working on it.

Make no mistake about this, it takes time. You won't fix something as ugly as this real fast. There will be mud....

Why don't i just buy another hood? They cost $550 new, and that's for an aftermarket hood that may not fit properly, besides, i don't have $550 .

.

A couple pictures, one of before sandblasting, after, and one of it worked on a bit with it having been etch primered and given a couple coats of primer to prevent rust.

If i have time, i'm going to take out the big one on the right side and the smaller one in the middle today.

My test subject is the hood to my blue car that was a little rough in the first place, then i took it to my media blasters to have them clean the paint around the edges and the supports underneath.

Well, the blasters got in a hurry and just blasted the entire underneath side

. This warped the hell out of the flat unsupported surface of the hood. Sandblasting creates a lot of heat on metal, thin surfaces like a hood skin should never be blasted with sand, use something like crushed walnut shells or soda blasting.

. This warped the hell out of the flat unsupported surface of the hood. Sandblasting creates a lot of heat on metal, thin surfaces like a hood skin should never be blasted with sand, use something like crushed walnut shells or soda blasting.I'll get a picture of the tools i'm using and a couple of me working out one of the larger warps. You'll see in the pictures i'm posting that i've already been working on it.

Make no mistake about this, it takes time. You won't fix something as ugly as this real fast. There will be mud....

Why don't i just buy another hood? They cost $550 new, and that's for an aftermarket hood that may not fit properly, besides, i don't have $550

.

.A couple pictures, one of before sandblasting, after, and one of it worked on a bit with it having been etch primered and given a couple coats of primer to prevent rust.

If i have time, i'm going to take out the big one on the right side and the smaller one in the middle today.

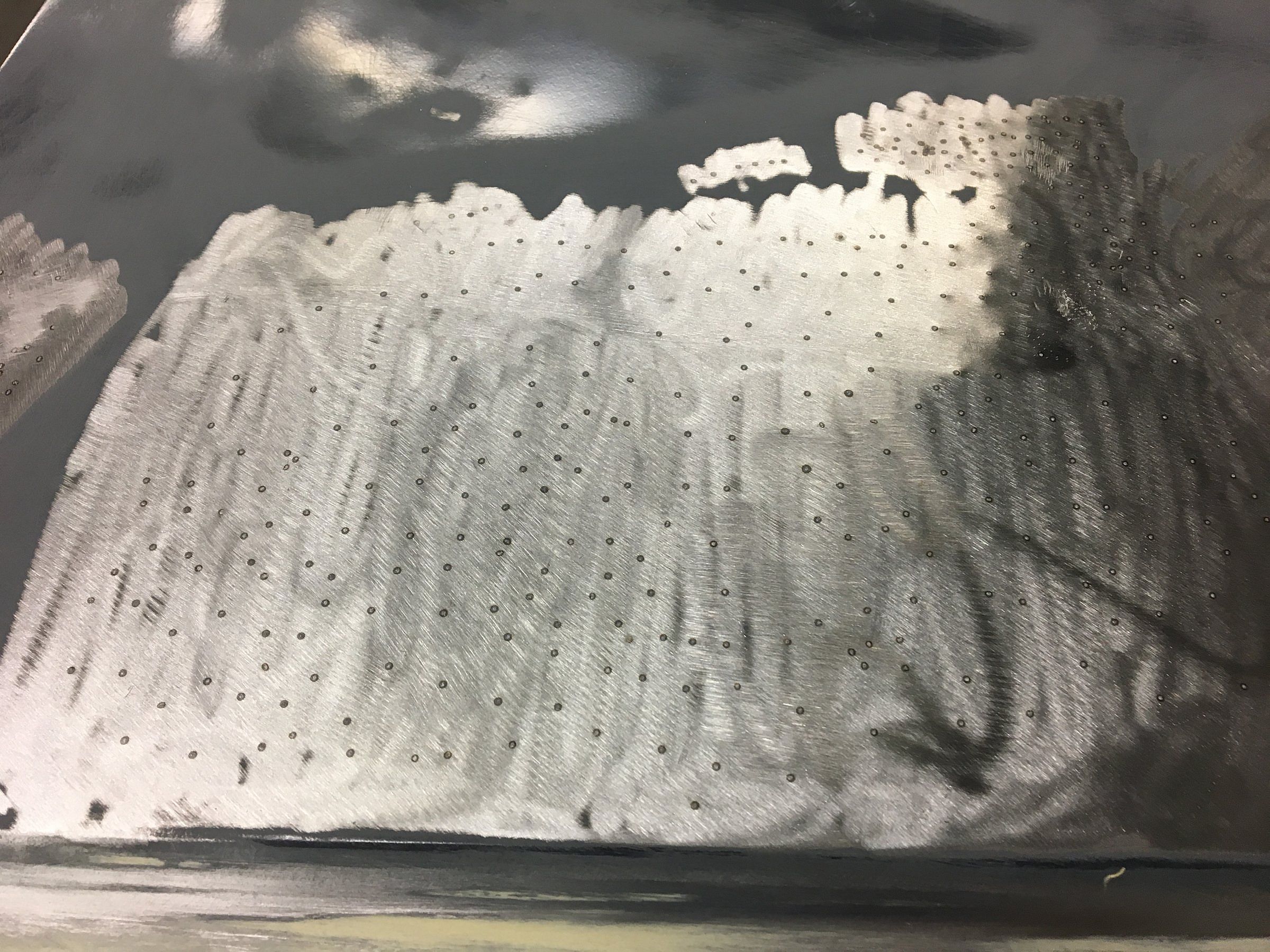

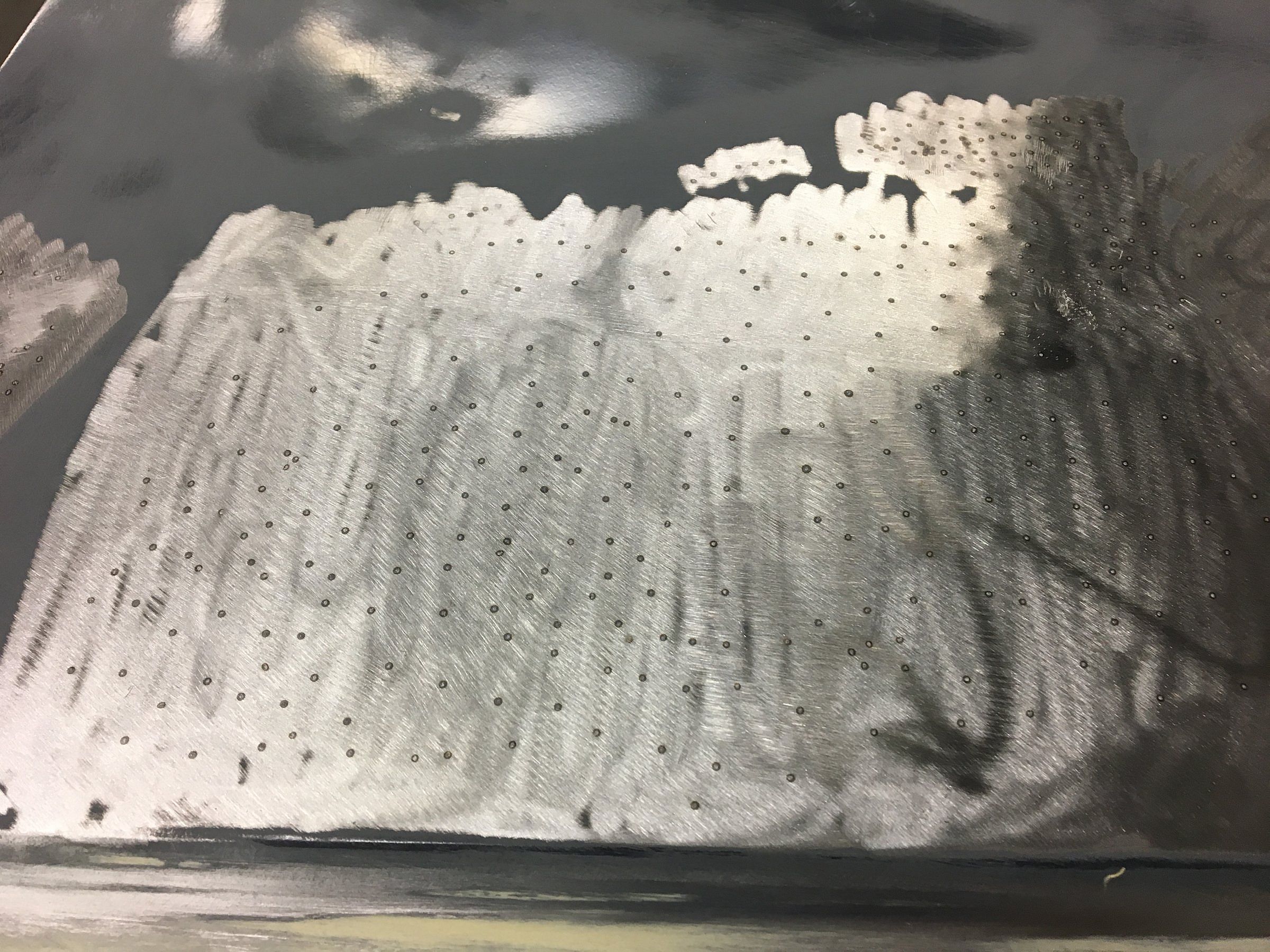

Here's a little progress with some of the tools I'm using.

The puller is a great device, it's used similar to a nail gun except you don't tack on studs. It has a magnetic ground that you put on a bare metal spot close to where your working and using the long electrode end, you press the button and it tacks itself to the surface. It has a small slide hammer on the electrode that you slide up against the handle to pull out the dent.

When you have high spots, you use the smaller electrode and turn up the amperage and it shrinks down the metal.

First thing is to grind off all the primer and make a nice clean metal surface. This is just like welding, you'll want the area you're working clean of all paint and dirt.

It takes a lot of hits to shrink up the metal as you'll see in the third picture. You go in a circular pattern starting on the outside of the stretched area and work concentric circles heading toward the middle. It took maybe a hundred and fifty whacks with the puller for this one dent. But it's fast, I might spend three or four seconds on each pull.

That area feels very tight and solid now. Now I can commence with the hammer and dolly stage to flatten the small dents out. I'll use a metal file to knock down the little tips left from the puller and give it it's initial straightness before slinging mud.

The puller is a great device, it's used similar to a nail gun except you don't tack on studs. It has a magnetic ground that you put on a bare metal spot close to where your working and using the long electrode end, you press the button and it tacks itself to the surface. It has a small slide hammer on the electrode that you slide up against the handle to pull out the dent.

When you have high spots, you use the smaller electrode and turn up the amperage and it shrinks down the metal.

First thing is to grind off all the primer and make a nice clean metal surface. This is just like welding, you'll want the area you're working clean of all paint and dirt.

It takes a lot of hits to shrink up the metal as you'll see in the third picture. You go in a circular pattern starting on the outside of the stretched area and work concentric circles heading toward the middle. It took maybe a hundred and fifty whacks with the puller for this one dent. But it's fast, I might spend three or four seconds on each pull.

That area feels very tight and solid now. Now I can commence with the hammer and dolly stage to flatten the small dents out. I'll use a metal file to knock down the little tips left from the puller and give it it's initial straightness before slinging mud.

Kind of yes and no, depends how long the paint has been delaminating.

If it's been awhile, the base coat underneath the clear will absorb various chemicals from the air and gives you an unstable base for your topcoat.

Generally, you can feather out the peeling clearcoat and primer the area similar to what you would do with a repaired area. Allow it a few days to harden and shrink back, then block it out and continue with the rest of the refinishing process.

The only problem you'll have is the shrinking back off the materials you spray on the car. After a week or two you might see sanding lines or a ragged circle imprint if you refinish it too quick. The trick is letting the primer shrink back as much as you can. If you can let the primer sit for a week before sanding it, or more, the better the end result will be in the long term.

Post a picture of your problem, i'll tell you what i would advise for your situation.

Sorry it took so long to get pics but here they are...

It will need to be stripped.Sorry it took so long to get pics but here they are...

The problem with large areas of delamination like that is that the underlying basecoat has had time to soak up crap in the air and rain. You would have bad results trying to paint over that.

It will need to be stripped.

The problem with large areas of delamination like that is that the underlying basecoat has had time to soak up crap in the air and rain. You would have bad results trying to paint over that.

Thanks Dave. In your experience, what would you say is the best, easiest way to strip it? I'm not looking for a show finish but I do want it to look decent. Maybe I'll paint it that blue you painted. That paint was pretty awesome.

You can use a DA sander with some 80 grit.Thanks Dave. In your experience, what would you say is the best, easiest way to strip it? I'm not looking for a show finish but I do want it to look decent. Maybe I'll paint it that blue you painted. That paint was pretty awesome.

Chemical strippers are an option too, you'll just need to be careful with them. If you want to go this route, ask me specifically about it. It's kind of long winded.

Of course there is the option of a media blaster. Just make sure THEY'RE NOT USING SAND

to blast the paint away.

to blast the paint away.You can use a DA sander with some 80 grit.

Chemical strippers are an option too, you'll just need to be careful with them. If you want to go this route, ask me specifically about it. It's kind of long winded.

Of course there is the option of a media blaster. Just make sure THEY'RE NOT USING SANDto blast the paint away.

I'm going to have to do this myself so media blasting is probably not practical. I've heard that one of the biggest problems with using chemical strippers is neutralizing and removing the stripper.

Similar threads

- Replies

- 21

- Views

- 3K

- Replies

- 18

- Views

- 2K

Wheels-Tires

10 Hole Rim Restore options?

- Replies

- 23

- Views

- 2K

- Replies

- 19

- Views

- 2K