OH WHAT A LONG DAY! you will not believe how far i got today, lets start from the begining.

the trunk devider was first ,just set right in place. welded the drivers rear bumper mount down. the tail panel was next, again no problems. had to assemble the roof support only took about 30 minuets

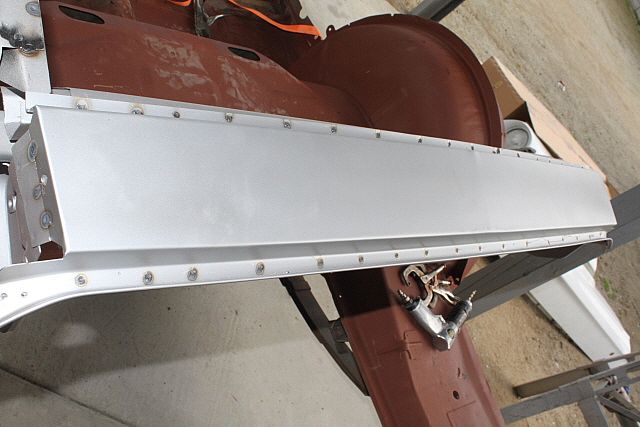

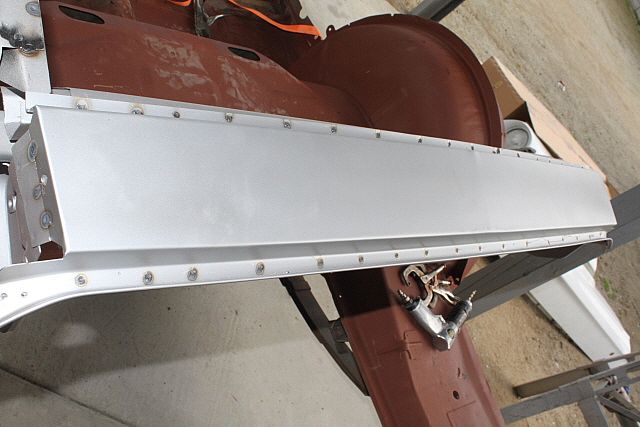

with my spot welder,you have to get one of these talk about a time saver. set the drivers side in place and measured several times before welding in place get it right the first time you will not believe how solid it is when welded it will not move more than an 1/8 inch once welded .attached the wheel tub bracket that the roof support attaches to. the roof support brace was next welding to the wheel tub outer lip and then to the roof support ,i measured Johnnys car but i didn't need to it automaticly lines right up in the correct spot .do not weld the support to the trunk devider you may need to adjust the window opening and that spot will move if needed. went inside and welded the inner plate on the rear door post. then welded the rain gutter in ,cant go wrong it lines right up. the drivers side was finnished went to the pass. side and did it all over again. when the pass side was finnished i moved on to the rear roof support .i checked it with the roof skin to make sure it was in the right spot ,again you cant go wrong it has a troff it sets in . the rear window bottom was next it sets on the trunk devider again you can't mess up its a tight fit. but still do not weld to the roof support. now we come to the drivers quarter and thats when the night mare comes in. the points at the door jamb fit at the scoop ,but form the top of the scoop to the top at the door is a 1/4 inch short and very noticable i may have to split the edge at the top of the door and lift it . then we get to the rear window bottom .it is tight at the top edge with a 1/8 gap at the bottom edge i will have to split it and spread it and weld it back no i welded the trunk devider and the quarter together after measuring several times. then we get to the trunklid opening the shape of the trunk opening at the quarter was way off it was to low about 1/2 inch below the trunk lid but fit at the rear window. after sever minutes with a porta power i was able to raise it . i have to finnish welding the quarter tomarrow then its on to the pass side and then the roof and i will ,believe it or not probably be finnished tomarrow

the trunk devider was first ,just set right in place. welded the drivers rear bumper mount down. the tail panel was next, again no problems. had to assemble the roof support only took about 30 minuets

with my spot welder,you have to get one of these talk about a time saver. set the drivers side in place and measured several times before welding in place get it right the first time you will not believe how solid it is when welded it will not move more than an 1/8 inch once welded .attached the wheel tub bracket that the roof support attaches to. the roof support brace was next welding to the wheel tub outer lip and then to the roof support ,i measured Johnnys car but i didn't need to it automaticly lines right up in the correct spot .do not weld the support to the trunk devider you may need to adjust the window opening and that spot will move if needed. went inside and welded the inner plate on the rear door post. then welded the rain gutter in ,cant go wrong it lines right up. the drivers side was finnished went to the pass. side and did it all over again. when the pass side was finnished i moved on to the rear roof support .i checked it with the roof skin to make sure it was in the right spot ,again you cant go wrong it has a troff it sets in . the rear window bottom was next it sets on the trunk devider again you can't mess up its a tight fit. but still do not weld to the roof support. now we come to the drivers quarter and thats when the night mare comes in. the points at the door jamb fit at the scoop ,but form the top of the scoop to the top at the door is a 1/4 inch short and very noticable i may have to split the edge at the top of the door and lift it . then we get to the rear window bottom .it is tight at the top edge with a 1/8 gap at the bottom edge i will have to split it and spread it and weld it back no i welded the trunk devider and the quarter together after measuring several times. then we get to the trunklid opening the shape of the trunk opening at the quarter was way off it was to low about 1/2 inch below the trunk lid but fit at the rear window. after sever minutes with a porta power i was able to raise it . i have to finnish welding the quarter tomarrow then its on to the pass side and then the roof and i will ,believe it or not probably be finnished tomarrow

. Do you have any pics of one that you have finished and sold? I'd love to see.

. Do you have any pics of one that you have finished and sold? I'd love to see.