New Accufab Throttle Body:

Goodbye, BBK TB. You whistle better than me, but your services will no longer be required.

Swapped a polished (too pretty for Black Jack) Accufab 70mm TB that I picked up for $210 in its place, tonight. The whistle at idle is gone! Unfortunately, it's been replaced by a much worse whistle at about 1/4 throttle. After some quick looking, I think it may be either of the following: 1. improper port-matching with the gaskets, 2. need to smooth the IAC port & perhaps TB blade, though whistling from an Accufab was not supposed to happen.

Could be either issue. I didn't closely check the gasket alignment when I put everything together, & perhaps the gasket shifted into the air stream. I'll pull it apart and check it in the next couple of days. However, 2 is still possible. I noticed when inspecting the TB that the IAC port into the TB has sharp edges and that the blade is roughly in its path at what I'd guess is around 1/4 throttle.

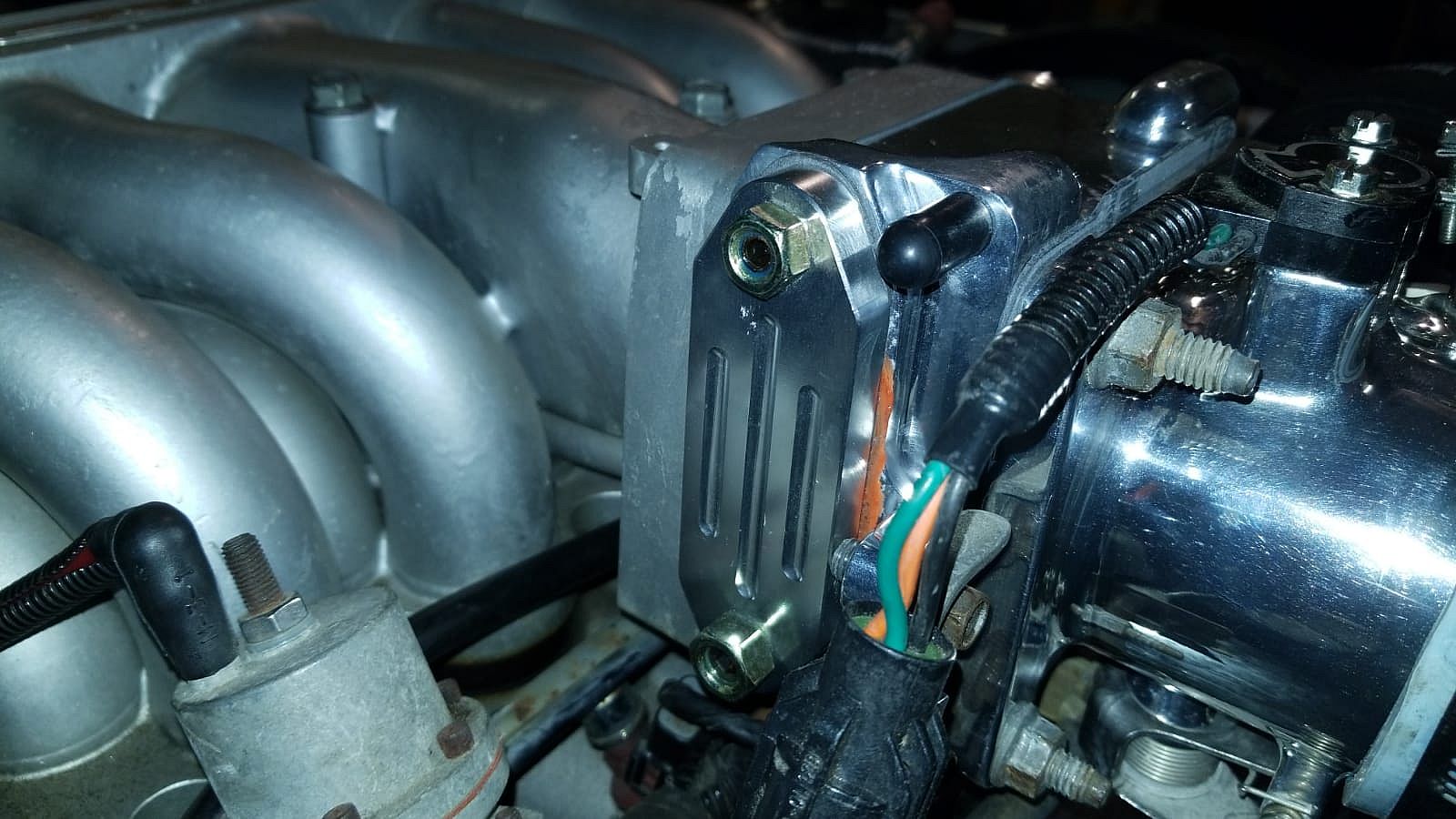

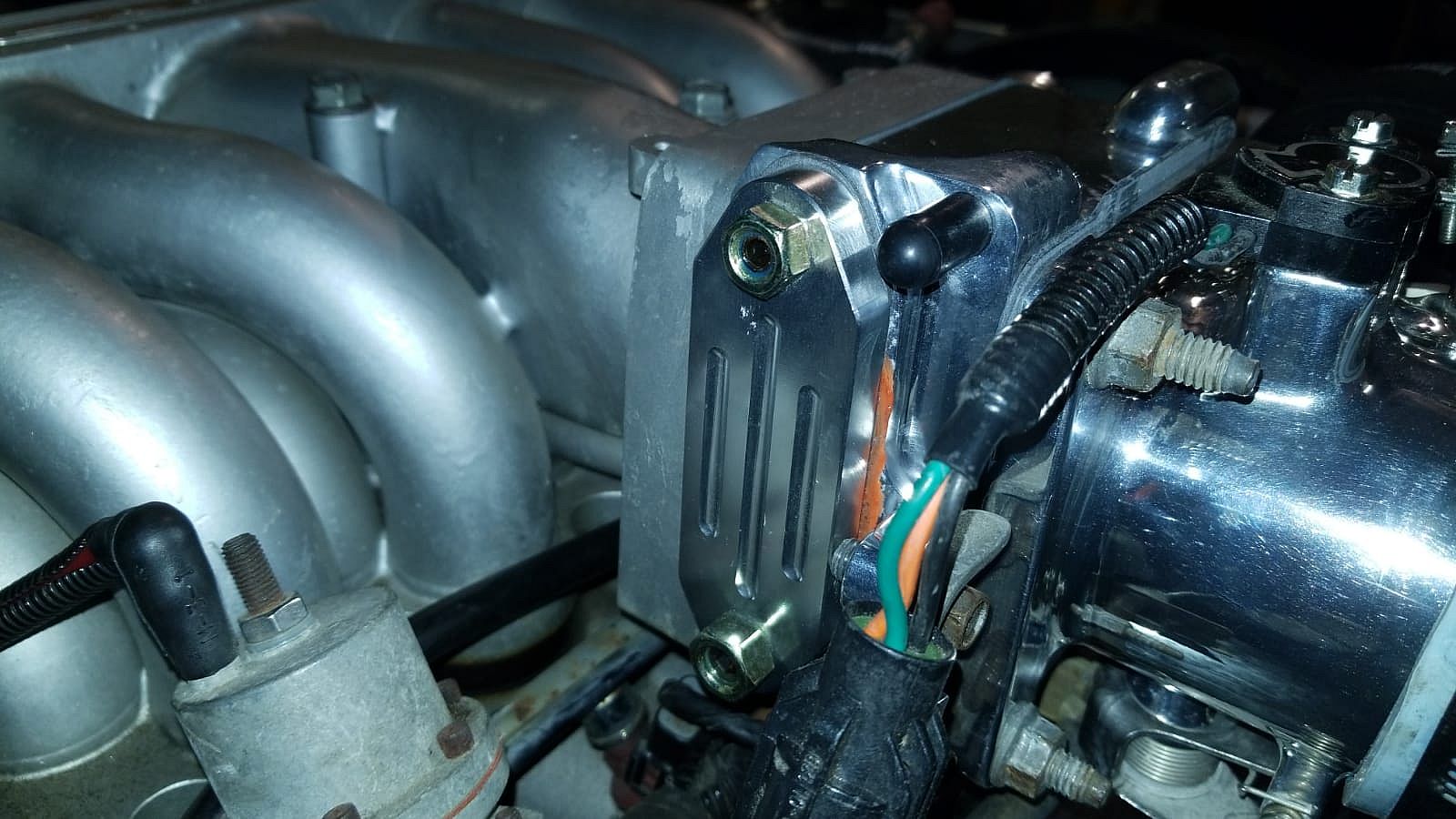

After pic:

EGR Delete

I pulled the EGR valve out while I was at it & replaced it with a blocking plate. I didn't like the look at the dirty intake plenum, and I want to clean up the engine bay over there, a bit. I plugged it back in for now & zip tied it behind the upper intake/head on the passenger side. Ultimately, based on a diagram provided in another thread, thanks @AeroCoupe, I'll come back to it to ensure the computer knows the EGR is non-functional, while hopefully refraining from giving a CEL.

TB spacer/Coolant Line bypass

Finally pulled those hoses off & that rear one was a PITA to scrape off with the little room I had to work with. I ran a new hose, bypassing the EGR spacer completely & it looks a little cleaner in that area, now.

Other Notes:

The TPS settled very nicely in at .95 volts. I tweaked the idle RPM a bit, but 900 on the gauge (who knows how accurate...) is what the car liked. I could get it down to ~750-800 but it would start to surge. At first I took a quick cruise and liked it, but then back to surging & even stalled the engine when I turned on the A/C. First rule of tuning: give the car what it likes! Now, other than the whistling sound, the car is running like a top.

I'm still holding onto the accufab race 70mm TB & may install it one day. It doesn't work with the BBK/MAC intake tract on the car & I don't care to spend hundreds on an aftermarket one, though I might fab up something that will work eventually. In any case, I took the opportunity to nab a pic of them side-by-side:

Notably, the race TB does not have a crankcase vent tube. Also, you can see how it has more of a chamfered, funnel from a 90mm port down to the 70mm blade. This is kinda useless behind my 75mm bullet MAF, though I might still try it out.

Cleaning the passenger corner of the bay:

Alright, it's been a while since I've taken this on, but is it as simple as just removing the TAB, TAD, and EGR controller? I have no smog pump, no cats, no EGR ports/tubes in the GT40X cylinder heads, which are plugged. Now, that I've removed the EGR Valve & its dedicated vacuum line from the intake vacuum port, which is capped, can I just remove these 3 gizmos attached to the strut tower? The vaccuum diagram (thanks @jrichker) seems to show me that I need to ensure vacuum runs from the check valve to a splitter that includes the reservoir & HVAC controls. Other than that, seems like I can remove all other vacuum lines without issue.

On the electrical side, it looks like (thanks, @Mustang5L5) the only thing I need to worry about is the proper EGR resistor. The TAB & TAD will apparently kick a code or two, but won't trip the CEL... fine by me.

Am I missing anything? Cleaning up this side of the engine bay will make room for my adjustable brake prop valve, which should be coming up soon.

Goodbye, BBK TB. You whistle better than me, but your services will no longer be required.

Swapped a polished (too pretty for Black Jack) Accufab 70mm TB that I picked up for $210 in its place, tonight. The whistle at idle is gone! Unfortunately, it's been replaced by a much worse whistle at about 1/4 throttle. After some quick looking, I think it may be either of the following: 1. improper port-matching with the gaskets, 2. need to smooth the IAC port & perhaps TB blade, though whistling from an Accufab was not supposed to happen.

Could be either issue. I didn't closely check the gasket alignment when I put everything together, & perhaps the gasket shifted into the air stream. I'll pull it apart and check it in the next couple of days. However, 2 is still possible. I noticed when inspecting the TB that the IAC port into the TB has sharp edges and that the blade is roughly in its path at what I'd guess is around 1/4 throttle.

After pic:

EGR Delete

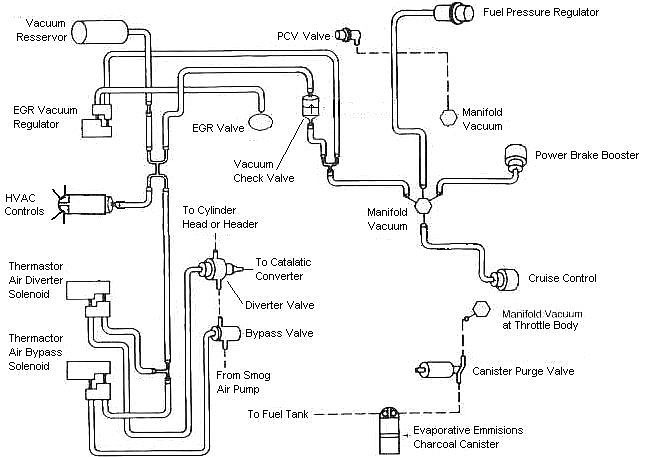

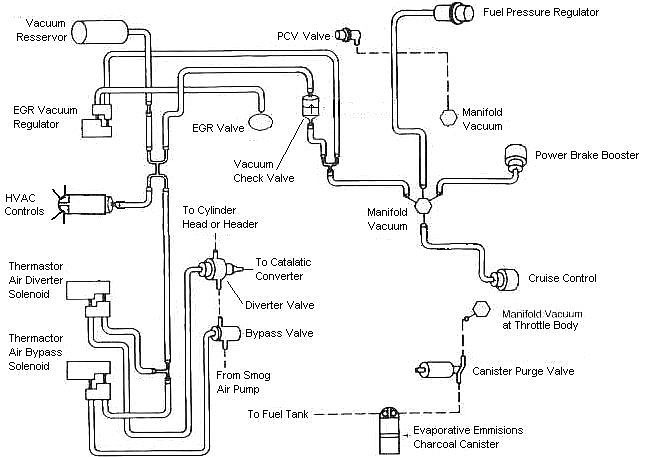

I pulled the EGR valve out while I was at it & replaced it with a blocking plate. I didn't like the look at the dirty intake plenum, and I want to clean up the engine bay over there, a bit. I plugged it back in for now & zip tied it behind the upper intake/head on the passenger side. Ultimately, based on a diagram provided in another thread, thanks @AeroCoupe, I'll come back to it to ensure the computer knows the EGR is non-functional, while hopefully refraining from giving a CEL.

TB spacer/Coolant Line bypass

Finally pulled those hoses off & that rear one was a PITA to scrape off with the little room I had to work with. I ran a new hose, bypassing the EGR spacer completely & it looks a little cleaner in that area, now.

Other Notes:

The TPS settled very nicely in at .95 volts. I tweaked the idle RPM a bit, but 900 on the gauge (who knows how accurate...) is what the car liked. I could get it down to ~750-800 but it would start to surge. At first I took a quick cruise and liked it, but then back to surging & even stalled the engine when I turned on the A/C. First rule of tuning: give the car what it likes! Now, other than the whistling sound, the car is running like a top.

I'm still holding onto the accufab race 70mm TB & may install it one day. It doesn't work with the BBK/MAC intake tract on the car & I don't care to spend hundreds on an aftermarket one, though I might fab up something that will work eventually. In any case, I took the opportunity to nab a pic of them side-by-side:

Notably, the race TB does not have a crankcase vent tube. Also, you can see how it has more of a chamfered, funnel from a 90mm port down to the 70mm blade. This is kinda useless behind my 75mm bullet MAF, though I might still try it out.

Cleaning the passenger corner of the bay:

Alright, it's been a while since I've taken this on, but is it as simple as just removing the TAB, TAD, and EGR controller? I have no smog pump, no cats, no EGR ports/tubes in the GT40X cylinder heads, which are plugged. Now, that I've removed the EGR Valve & its dedicated vacuum line from the intake vacuum port, which is capped, can I just remove these 3 gizmos attached to the strut tower? The vaccuum diagram (thanks @jrichker) seems to show me that I need to ensure vacuum runs from the check valve to a splitter that includes the reservoir & HVAC controls. Other than that, seems like I can remove all other vacuum lines without issue.

On the electrical side, it looks like (thanks, @Mustang5L5) the only thing I need to worry about is the proper EGR resistor. The TAB & TAD will apparently kick a code or two, but won't trip the CEL... fine by me.

Am I missing anything? Cleaning up this side of the engine bay will make room for my adjustable brake prop valve, which should be coming up soon.

Last edited:

. Contact the city and see if they’ll cover the damage from the pothole if that ever happens again. Had a friend who had two wheels replaced on his truck when it hit a pothole, all covered by the city.

. Contact the city and see if they’ll cover the damage from the pothole if that ever happens again. Had a friend who had two wheels replaced on his truck when it hit a pothole, all covered by the city.