It has been an arduous, long, slow process (with a new wife and new house pushing the Mustang to the back burner), but here are some updates.

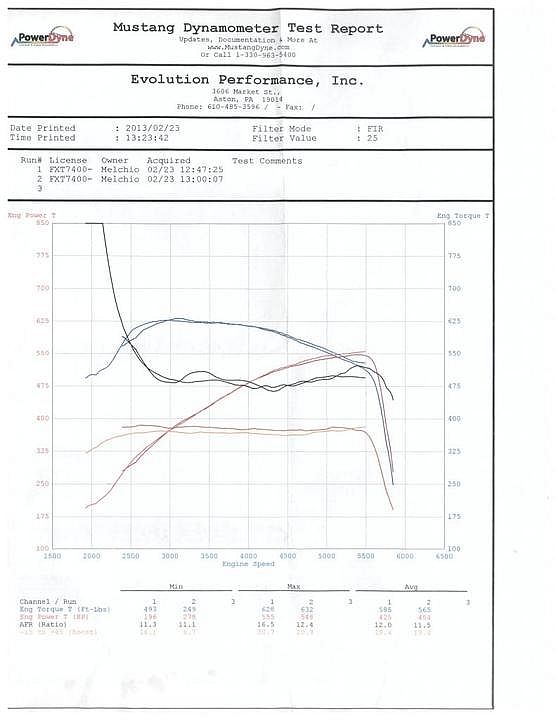

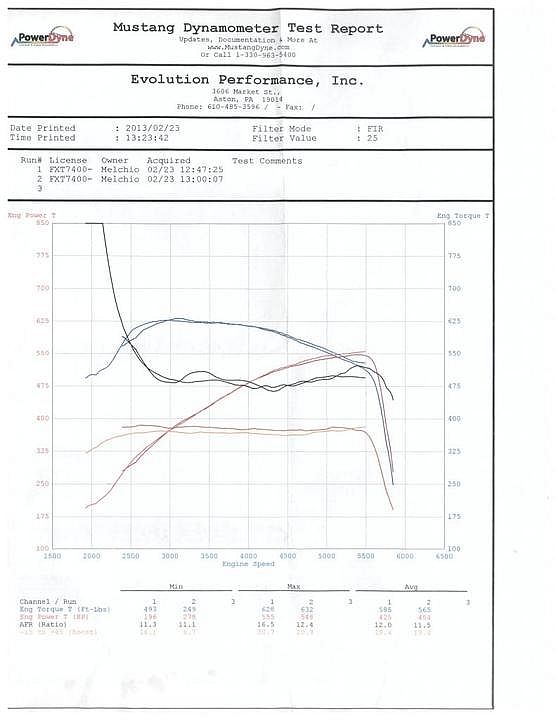

I finally got it on the dyno a couple of weeks ago, and it put down 655 ft-lbs of torque at around 2500 rpm (as soon as the throttle hit the floor) on its first pull. It was making about 19.5 psi of boost on 93 octane, which is pushing it. We splashed some VP 110 octane into the tank for safety, and Jon set the rev limiter higher for a max power pull.

Alas, it only made 550 rwhp at 5500 rpm. Jon cut the pull off early, as he saw the power and torque dropping dramatically, and we all heard a pronounced change in engine noise. As it turns out, the valves floated around 4150 rpm, as you can see by the inflection point in the hp and torque curves:

Needless to say, I was bummed, almost to the point of denial. I drove it home, and the first thing I did was a leakdown test. No cylinder had any measurable leakdown, so I dodged a bullet there. I then pulled the valve covers, and called Modular Head Shop as I was supposed to received Stage 3 valve springs with my heads. After consulting with Jordan, we determined that they inadvertently used Stage 2 valve springs when building my heads! They handled the situation admirably, however, and sent me the correct valve springs with no questions asked and no out-of-pocket expenses for me.

Of course, actually installing the new valve springs was up to me. I don't know how many of you have swapped valve springs with the engine in the car, but it was a bitch. It took about 6 hours with a helper.

The car then sat for a few weeks, until yesterday when I finally had some time to put things back together again.

I got her buttoned up, and turned the key. It lit off for a few revs, then died with a loud grinding noise. My wife, who was watching the engine bay for leaks / smoke / fire, nearly jumped out of her skin lol. After racking my brain for a few moments, I realized the horrible truth:

I left a rag in the intake! With a pit in my stomach, I tore into the Mustang again. I eventually reached the TVS's gaping intake, and found some tattered rag fragments to confirm my worst fears. The engine was seized at this point.

Thinking it was the only way to potentially salvage my engine / supercharger, I took the drain plug out of the blower, took the snout off, and inspected the gears that keep both rotors meshed. The driver's side gear had three dowels on it that the snout engages to drive the supercharger. A lightbulb went off in my head, and I dug around for a tool I had used to change my Miata's timing belt. As it turns out, this tool had two holes drilled in it that were exactly the same distance apart as two of the three dowels on the TVS gear! I placed the tool on the dowels, grabbed some gloves, and pulled on the tool counter-clockwise to attempt to untangle the rag from the TVS's lobes. After what I thought to be more than enough force, the blower turned backwards just enough to expose a large rag fragment. To make a long story short, I was able to use a combination of my fingers, my wife's (thinner) fingers, an intentionally blunted 90 degree pick, and a flexible claw tool, to extract all rag remnants from the supercharger. When it finally spun freely (more-or-less), I put everything back together, and fired the Mustang up again. It ran! I immediately took it out on the nearest highway to confirm it still made boost, and amazingly, it did.

Those TVS blowers are tough sons of bitches. I can't believe it wasn't damaged, but all seems to be well. Next step is to put it back on the dyno and see how much it makes on a clean pull. Then, it's off to Cecil!

I finally got it on the dyno a couple of weeks ago, and it put down 655 ft-lbs of torque at around 2500 rpm (as soon as the throttle hit the floor) on its first pull. It was making about 19.5 psi of boost on 93 octane, which is pushing it. We splashed some VP 110 octane into the tank for safety, and Jon set the rev limiter higher for a max power pull.

Alas, it only made 550 rwhp at 5500 rpm. Jon cut the pull off early, as he saw the power and torque dropping dramatically, and we all heard a pronounced change in engine noise. As it turns out, the valves floated around 4150 rpm, as you can see by the inflection point in the hp and torque curves:

Needless to say, I was bummed, almost to the point of denial. I drove it home, and the first thing I did was a leakdown test. No cylinder had any measurable leakdown, so I dodged a bullet there. I then pulled the valve covers, and called Modular Head Shop as I was supposed to received Stage 3 valve springs with my heads. After consulting with Jordan, we determined that they inadvertently used Stage 2 valve springs when building my heads! They handled the situation admirably, however, and sent me the correct valve springs with no questions asked and no out-of-pocket expenses for me.

Of course, actually installing the new valve springs was up to me. I don't know how many of you have swapped valve springs with the engine in the car, but it was a bitch. It took about 6 hours with a helper.

The car then sat for a few weeks, until yesterday when I finally had some time to put things back together again.

I got her buttoned up, and turned the key. It lit off for a few revs, then died with a loud grinding noise. My wife, who was watching the engine bay for leaks / smoke / fire, nearly jumped out of her skin lol. After racking my brain for a few moments, I realized the horrible truth:

I left a rag in the intake! With a pit in my stomach, I tore into the Mustang again. I eventually reached the TVS's gaping intake, and found some tattered rag fragments to confirm my worst fears. The engine was seized at this point.

Thinking it was the only way to potentially salvage my engine / supercharger, I took the drain plug out of the blower, took the snout off, and inspected the gears that keep both rotors meshed. The driver's side gear had three dowels on it that the snout engages to drive the supercharger. A lightbulb went off in my head, and I dug around for a tool I had used to change my Miata's timing belt. As it turns out, this tool had two holes drilled in it that were exactly the same distance apart as two of the three dowels on the TVS gear! I placed the tool on the dowels, grabbed some gloves, and pulled on the tool counter-clockwise to attempt to untangle the rag from the TVS's lobes. After what I thought to be more than enough force, the blower turned backwards just enough to expose a large rag fragment. To make a long story short, I was able to use a combination of my fingers, my wife's (thinner) fingers, an intentionally blunted 90 degree pick, and a flexible claw tool, to extract all rag remnants from the supercharger. When it finally spun freely (more-or-less), I put everything back together, and fired the Mustang up again. It ran! I immediately took it out on the nearest highway to confirm it still made boost, and amazingly, it did.

Those TVS blowers are tough sons of bitches. I can't believe it wasn't damaged, but all seems to be well. Next step is to put it back on the dyno and see how much it makes on a clean pull. Then, it's off to Cecil!