Grounds

Revised 28-Oct-2012 to add signal ground description & possible problems if it is bad

Grounds are important to any electrical system, and especially to computer controlled engines.

In an automobile, the ground is the return path for power to get back to the alternator and battery.

Make sure that all the ground places are clean and shiny bare metal: no paint, no corrosion.

1.) The main power ground is from engine block to battery: it is the power ground for the starter & alternator.

2.) The secondary power ground is between the back of the intake manifold and the driver's side firewall. It is often missing or loose. It supplies ground for the alternator, A/C compressor clutch and other electrical accessories such as the gauges. The clue to a bad ground here is that the temp gauge goes up as you add electrical load such as heater, lights and A/C.

Any car that has a 3G or high output current alternator needs a 4 gauge ground wire running from the block to the chassis ground where the battery pigtail ground connects. The 3G has a 130 amp capacity, so you wire the power side with 4 gauge wire. It stands to reason that the ground side handles just as much current, so it needs to be 4 gauge too.

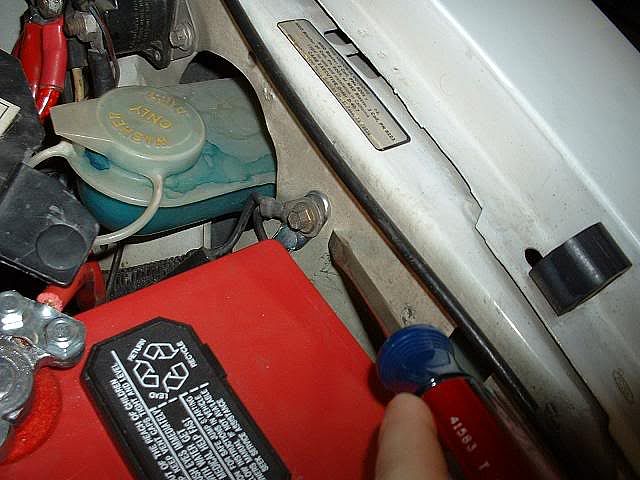

The picture shows the common ground point for the battery , computer, & extra 3G alternator ground wire as described above in paragraph 2. A screwdriver points to the bolt that is the common ground point.

The battery common ground is a 10 gauge pigtail with the computer ground attached to it.

Picture courtesy timewarped1972

Correct negative battery ground cable.

3.) The computer's main power ground (the one that comes from the battery ground wire) uses pins 40 & 60 for all the things it controls internally: it comes off the ground pigtail on the battery ground wire. Due to its proximity to the battery, it may become corroded by acid fumes from the battery.

In 86-90 model cars, it is a black cylinder about 2 1/2" long by 1" diameter with a black/lt green wire.

In 91-95 model cars it is a black cylinder about 2 1/2" long by 1" diameter with a black/white wire.

You'll find it up next to the starter solenoid where the wire goes into the wiring harness.

All the grounds listed in items 1,2 & 3 need to bolt to clean, shiny bare metal. A wire brush or some fine sandpaper is the best thing to use to clean the ground connections.

4.) All the sensors have a common separate signal ground. This includes the TPS, ACT, EGR, BAP, & VSS sensors. This ground is inside the computer and connects pin 46 to pins 40 & 60, which are the main computer grounds. If this internal computer ground gets damaged, you won't be able to dump codes and the car will have idle/stall/ performance problems

5.) The O2 sensor heaters have their own ground (HEGO ground) coming from the computer. This is different and separate from the O2 sensor ground. It is an orange wire with a ring terminal on it. It is located in the fuel injector wiring harness and comes out under the throttle body. It gets connected to a manifold or bolt on back of the cylinder head.

6.) The TFI module has 2 grounds: one for the foil shield around the wires and another for the module itself. The TFI module ground terminates inside the computer.

7.) The computer takes the shield ground for the TFI module and runs it from pin 20 to the chassis near the computer.

See http://assets.fluke.com/appnotes/automotive/beatbook.pdf for help for help troubleshooting voltage drops across connections and components. Be sure to have the maximum load on a circuit when testing voltage drops across connections. As current across a defective or weak connection, increases so does the voltage drop. A circuit or connection may check out good with no load or minimal load, but show up bad under maximum load conditions. .

Voltage drops should not exceed the following:

200 mV Wire or cable

300 mV Switch

100 mV Ground

0 mV to <50 mV Sensor Connections

0.0V bolt together connections

Extra grounds are like the reserve parachute for a sky diver. If the main one fails, there is always your reserve.

The best plan is to have all the grounds meet at one central spot and connect together there. That eliminates any voltage drops from grounds connected at different places. A voltage drop between the computer ground and the alternator power ground will effectively reduce the voltage available to the computer by the amount of the drop.