I probably could have started this thread a year ago when I really got back to work on this long neglected project. I did post a bit on it in the welcome forum.

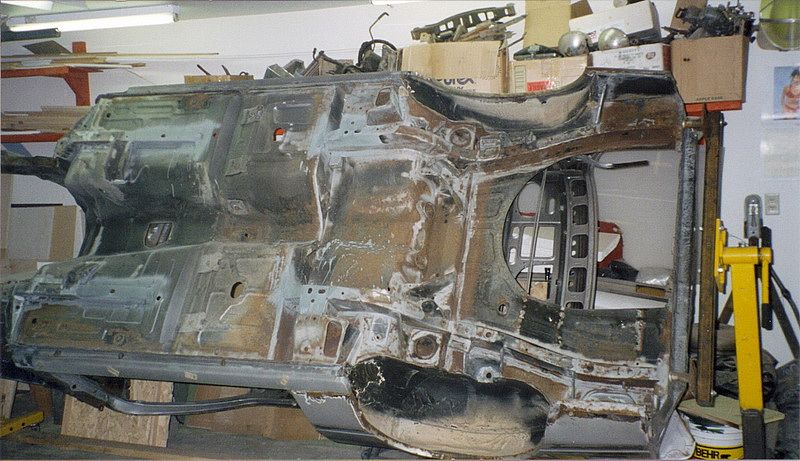

The background on this car; I bought it in 89 as a project to recieve the 302 engine I had built while working as a mechanic in an engine shop. It had a blown 2.3 engine and auto trans and was a bit shabby in the appearance department. The good thing was, there was not too much rust in the structure, just superficial rust for the most part. I tore the car down and started working on it, but other priorities in life kept cropping up and the progress slowed then stopped all together. I didn't do any work on the car for nearly 20 years. I moved the shell around, stored the parts that I'd kept and it all gathered dust.

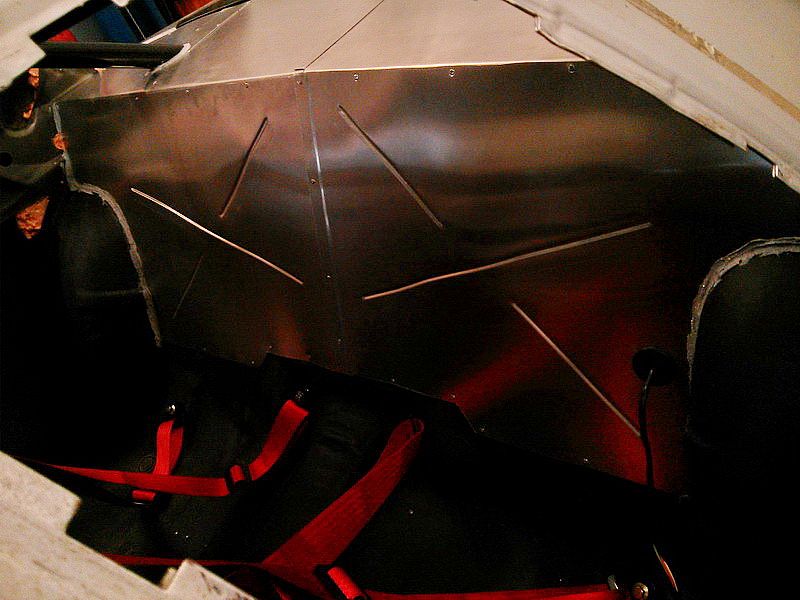

Last summer (2014) I finally decided I had no good excuses not to get working on it if I was seriously going to do so. So I started. I finished cleaning up the shell, welded in a 10 point cage and started ordering parts. I went with a full Maximum Motorsports suspension kit as my plan is to do some Autocross with the car, but I want it to be street legal too - just barely. By Christmas I had the car on wheels for the first time in years. Next was to start getting the drivetrain into it. The engine came out of the crate and the remaining parts to complete it were installed and into the car it went along with a freshly rebuilt T5. Slowly I worked at it over the remainder of the winter and at times during the warmer months. This past month I've been working pretty steady at it again and reached a significant stage yesterday. I started it up and have it running for the first time ever.

The background on this car; I bought it in 89 as a project to recieve the 302 engine I had built while working as a mechanic in an engine shop. It had a blown 2.3 engine and auto trans and was a bit shabby in the appearance department. The good thing was, there was not too much rust in the structure, just superficial rust for the most part. I tore the car down and started working on it, but other priorities in life kept cropping up and the progress slowed then stopped all together. I didn't do any work on the car for nearly 20 years. I moved the shell around, stored the parts that I'd kept and it all gathered dust.

Last summer (2014) I finally decided I had no good excuses not to get working on it if I was seriously going to do so. So I started. I finished cleaning up the shell, welded in a 10 point cage and started ordering parts. I went with a full Maximum Motorsports suspension kit as my plan is to do some Autocross with the car, but I want it to be street legal too - just barely. By Christmas I had the car on wheels for the first time in years. Next was to start getting the drivetrain into it. The engine came out of the crate and the remaining parts to complete it were installed and into the car it went along with a freshly rebuilt T5. Slowly I worked at it over the remainder of the winter and at times during the warmer months. This past month I've been working pretty steady at it again and reached a significant stage yesterday. I started it up and have it running for the first time ever.