You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Build Thread Enola- Finishing touches

- Thread starter a91what

- Start date

-

Sponsors (?)

For way less than that, you could single turbo that mother. I'd venture to say $600.... Except you already have a FMIC, so knock $300 off of that.

That is what I'm sayin',.......and then you'll be able to get reacquainted with the 4 spark plugs that think that you've forsaken them.For way less than that, you could single turbo that mother. I'd venture to say $600.... Except you already have a FMIC, so knock $300 off of that.

- Mar 2, 2015

- 6,811

- 5,849

- 203

We need a mic drop smiley.

*edit - or dare I say.... Mike drop?

See what I did there?

- Mar 2, 2015

- 6,811

- 5,849

- 203

I like what you're doing with this car....challenging your fabrication and tuning skills. Its cool seeing you rack your brain solving issues and calculating shortfalls. That's what this is all about.

There was a guy that made a m112 and m122 intake for our cars. The problem is he was a crook and ( from what I read ) had a few bad habits. People were all over the net trying to buy these things from him. They did actually work. I've seen one complete tuning kit on a car here in Maryland. It was awesome. I'm not telling you to change your car.

He used sheets of steel welded together and bolted to an explorer lower. The supercharger then bolted to that. Extended the nose and ran a supercharger crank pulley.

How do I know about this....because I almost sent him money for one before the forums let me know he ran off with their money. Smh

There was a guy that made a m112 and m122 intake for our cars. The problem is he was a crook and ( from what I read ) had a few bad habits. People were all over the net trying to buy these things from him. They did actually work. I've seen one complete tuning kit on a car here in Maryland. It was awesome. I'm not telling you to change your car.

He used sheets of steel welded together and bolted to an explorer lower. The supercharger then bolted to that. Extended the nose and ran a supercharger crank pulley.

How do I know about this....because I almost sent him money for one before the forums let me know he ran off with their money. Smh

Doubt it will be of any help,but another thread I follow,guy is restoring an older Blower car,his brackets and mounting of the sc (though the pretty common way to do it) looked slightly different than norm.

Here's the thread

http://www.stangnet.com/mustang-for...ezs-83-convertible.893706/page-4#post-9006178

And here's a couple of the pics

Here's the thread

http://www.stangnet.com/mustang-for...ezs-83-convertible.893706/page-4#post-9006178

And here's a couple of the pics

Yes I follow that thread as well. The Kennebell is a larger more capable unit than my little m90. It is also available as a kit, which is what you see in those pics. All of that was engineered to work with alot of R&D... my chit is homemadeDoubt it will be of any help,but another thread I follow,guy is restoring an older Blower car,his brackets and mounting of the sc (though the pretty common way to do it) looked slightly different than norm.

Here's the thread

http://www.stangnet.com/mustang-for...ezs-83-convertible.893706/page-4#post-9006178

And here's a couple of the pics

I remember the homemade part, I was lurking around on here for some of it lol.Yes I follow that thread as well. The Kennebell is a larger more capable unit than my little m90. It is also available as a kit, which is what you see in those pics. All of that was engineered to work with alot of R&D... my chit is homemade

I didn't figure it would be any help-but thought it was worth a shot for an idea or two on you current setup.

Got some chit done today, modified the SC. Now it didn't come out like a mpx but I think the flow has been significantly increased. I'll let the pictures tell the story...

first we tack in small pieces of metal scuff up the area then epoxy gets poured in. On the sides we used quick steel epoxy puddy.

first we tack in small pieces of metal scuff up the area then epoxy gets poured in. On the sides we used quick steel epoxy puddy.

marking it up for cutting.

marking it up for cutting.

rough cut.

rough cut.

the inside you can see the old port job.

the inside you can see the old port job.

let the porting begin!

let the porting begin!

inside the blower, you can clearly see how much material was removed. Broke through to the epoxy. I would have gone even further/deeper but.... I would have broken through the epoxy!

inside the blower, you can clearly see how much material was removed. Broke through to the epoxy. I would have gone even further/deeper but.... I would have broken through the epoxy!

before the surfacing... we used a long file to get it flat worked very well, I use silicone as a gasket anyway so no worries.

before the surfacing... we used a long file to get it flat worked very well, I use silicone as a gasket anyway so no worries.

you can see how much bigger the opening is now. I just cut the intake flange down and ported it to match.

you can see how much bigger the opening is now. I just cut the intake flange down and ported it to match.

So what do you think? Not bad for a few hours of work. And the epoxy will stay put it's sandwiched between the case and intake flange with plenty of ribbing to grab onto.

I'm also going from a 1.9 to a 2.3" pulley. Already have it on the shelf. That's a 2.9 drive ratio from the old 3.4 ratio.

I have a 2.7" pulley but it won't spin the blower fast enough (at least I think it wont).

So what do you think? Not bad for a few hours of work. And the epoxy will stay put it's sandwiched between the case and intake flange with plenty of ribbing to grab onto.

I'm also going from a 1.9 to a 2.3" pulley. Already have it on the shelf. That's a 2.9 drive ratio from the old 3.4 ratio.

I have a 2.7" pulley but it won't spin the blower fast enough (at least I think it wont).

OK so got her all back together and went for a long test drive. A few things to note, much less boost and it still slowly drops off (lowered the drive ratio so no surprise there), there is NO noticeable temperature rise in the intake.... The most I saw in the datalog was a 2* increase during a 3rd gear pull from 2500-5000rpm...

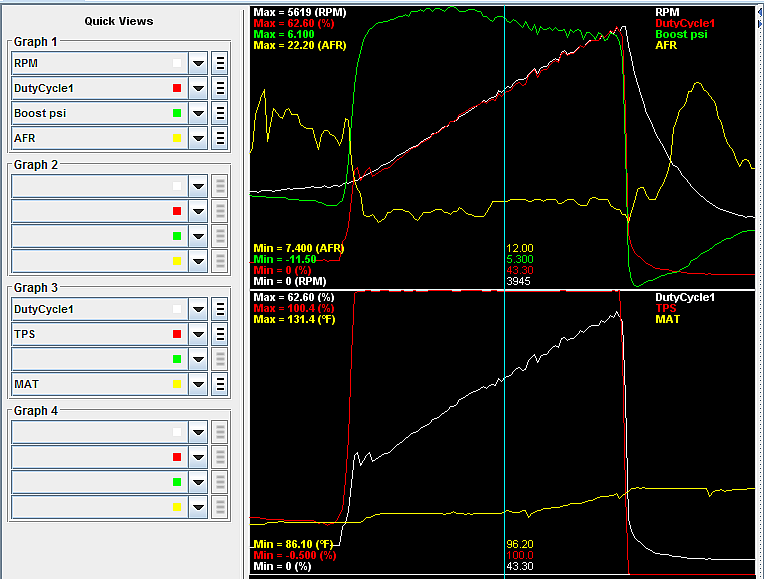

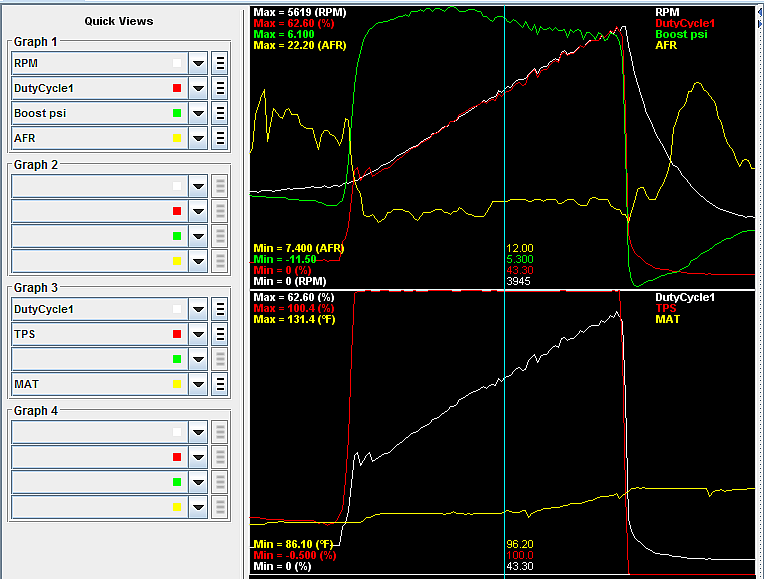

Here is a snip from the log.

manifold temp is the yellow line on the bottom graph, ignore the Max of 131.4*F that was heat soak from running into the store for a drink. started at 95* by end of pull had 97* in the intake that's much better than the 40* rise I was getting before!!!!!

manifold temp is the yellow line on the bottom graph, ignore the Max of 131.4*F that was heat soak from running into the store for a drink. started at 95* by end of pull had 97* in the intake that's much better than the 40* rise I was getting before!!!!!

Thinking about bypassing the intercooler and seeing what kind of boost loss I am seeing thru it and if it is even needed.

Here is a snip from the log.

Thinking about bypassing the intercooler and seeing what kind of boost loss I am seeing thru it and if it is even needed.

Last edited:

Hey.... that's a gen3 much better than what I started with. Lol.

Currently waiting on a new front seal.... no one carries it had to order online.

Larger pulley didn't make the grade and removing the intercooler and shortening the pipe run did net 2.3 psi. But Temps were too high for my liking. 190ish...

After seal comes in smaller pulley going back on for comparison to previous data logs that way it's apple to apples. Also going to put a vacuum gauge on the SC intake and see how much of a restriction the 75mm tb has become (if at all)... which posses the question how much vacuum behind the tb is considered "to much"?

Currently waiting on a new front seal.... no one carries it had to order online.

Larger pulley didn't make the grade and removing the intercooler and shortening the pipe run did net 2.3 psi. But Temps were too high for my liking. 190ish...

After seal comes in smaller pulley going back on for comparison to previous data logs that way it's apple to apples. Also going to put a vacuum gauge on the SC intake and see how much of a restriction the 75mm tb has become (if at all)... which posses the question how much vacuum behind the tb is considered "to much"?

@tmoss hasn't been active here in a while, but he may be able to help you with this question.Hey.... that's a gen3 much better than what I started with. Lol.

Currently waiting on a new front seal.... no one carries it had to order online.

Larger pulley didn't make the grade and removing the intercooler and shortening the pipe run did net 2.3 psi. But Temps were too high for my liking. 190ish...

After seal comes in smaller pulley going back on for comparison to previous data logs that way it's apple to apples. Also going to put a vacuum gauge on the SC intake and see how much of a restriction the 75mm tb has become (if at all)... which posses the question how much vacuum behind the tb is considered "to much"?

When it comes to the m90, you can slice it a bunch of different ways, but the results are all similar.

Too big of pulley, boost is low.

Small pulley, spins too fast, makes less power.

Intercooler? It's a restriction

No intercooler? Temps go up

Really good heads and cam? You swap aspirated power for naturally aspirated, power remains close to the same.

I spent years pondering ideas on the topic, but IMO all paths led to similar results. That's why I left good enough alone.

Bottom line it's a v6 supercharger on a v8.

When I think back to all the instacharger info I've found over the years, it would lead me to believe 9psi non intercooled is probably optimal and maximum.

If the setup was on top of the engine with the intercooler located in the upper intake like lightnings and cobras that would probably be much less restriction than plumbing it all over the place.

For the record, I probably shouldn't have even had it ported, caused a serious chain of expensive reactions. First it pegged the meter, then the fuel pump, then the injectors. Which then required a tune because there is no calibrated meters for my application. Luckily I know people in the business.

It was already on the edge of the stock 19's and I put it over the top.

Too big of pulley, boost is low.

Small pulley, spins too fast, makes less power.

Intercooler? It's a restriction

No intercooler? Temps go up

Really good heads and cam? You swap aspirated power for naturally aspirated, power remains close to the same.

I spent years pondering ideas on the topic, but IMO all paths led to similar results. That's why I left good enough alone.

Bottom line it's a v6 supercharger on a v8.

When I think back to all the instacharger info I've found over the years, it would lead me to believe 9psi non intercooled is probably optimal and maximum.

If the setup was on top of the engine with the intercooler located in the upper intake like lightnings and cobras that would probably be much less restriction than plumbing it all over the place.

For the record, I probably shouldn't have even had it ported, caused a serious chain of expensive reactions. First it pegged the meter, then the fuel pump, then the injectors. Which then required a tune because there is no calibrated meters for my application. Luckily I know people in the business.

It was already on the edge of the stock 19's and I put it over the top.

stop by bearing supply store and manage to find a seal for the front of a supercharger snout. got it into place with a smear of epoxy to hold it unfortunately it only held for about 20 miles as of right now there's oil all over my engine compartment again. in a last-ditch effort will be drilling 3 small holes in the snout centered on the seal once the seal is in place I will finish drilling into the seal then tap the holes for a small screw and use Loctite to hold them in. if this does not work someone let me know if they have a snout lying around the case is made of magnesium and cannot be welded.

on the bright side after the porting with a very loose belt I now see one extra pound of boost through the entire RPM band as exciting as it is to have 10 psi at 2500 rpm I opted to pull an extra degree and a half of timing right there I can't imagine the cylinder pressure is required to make 380 foot pounds of torque the wheels.

on the bright side after the porting with a very loose belt I now see one extra pound of boost through the entire RPM band as exciting as it is to have 10 psi at 2500 rpm I opted to pull an extra degree and a half of timing right there I can't imagine the cylinder pressure is required to make 380 foot pounds of torque the wheels.

Snout fix done.... looks okish... I guess I'm ready for this to be over so I can drive the car without worry.

I want to move onto the top/windows/paint.

I want to move onto the top/windows/paint.

Why am I only counting 6 ribs on the pulley? I thought you were gonna modify the drive to allow an 8 rib belt?

Ideally you would want 0" vacuum before t-body. Less than 2" is ok. More than that and you are leaving power on the table. I had 1.5 lbs pressure drop on my I/C set up as a reference.

Similar threads

- Replies

- 93

- Views

- 26K

expense.....

expense.....