Just so you get the idea of what I'm trying to do. Here are some starter pics.

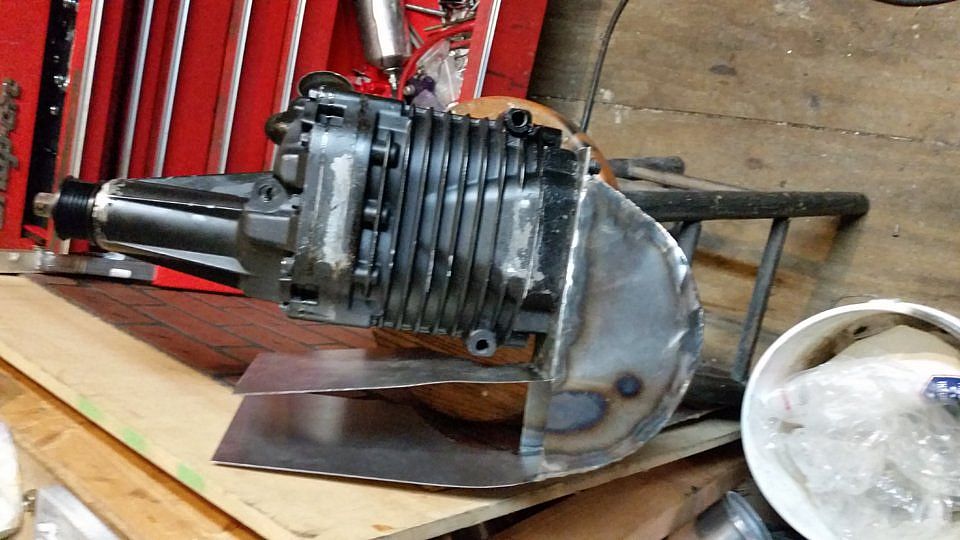

The flange has some angle tacked to it so it does not warp. The inlet opening is equivalent to a 2.5" pipe. I can safely use a 3"x3" square box to feed it, but it's going to be a larger area than that by the time I'm done.

Some 5/8 tubing will serve as a sleeve for the bolt that ends up inside the plenum.

The flange has some angle tacked to it so it does not warp. The inlet opening is equivalent to a 2.5" pipe. I can safely use a 3"x3" square box to feed it, but it's going to be a larger area than that by the time I'm done.

Some 5/8 tubing will serve as a sleeve for the bolt that ends up inside the plenum.