- May 8, 2006

- 703

- 240

- 84

Mike, I'm damn impressed. Is that the movie you demo your home theatre with? I had to use the avatar, it's the same look I get every time I end up getting asked to work on others cars when I planned on working on my own (just hear the "wwwhhhhhhhhhuuuuuuuuuuut" in the background.

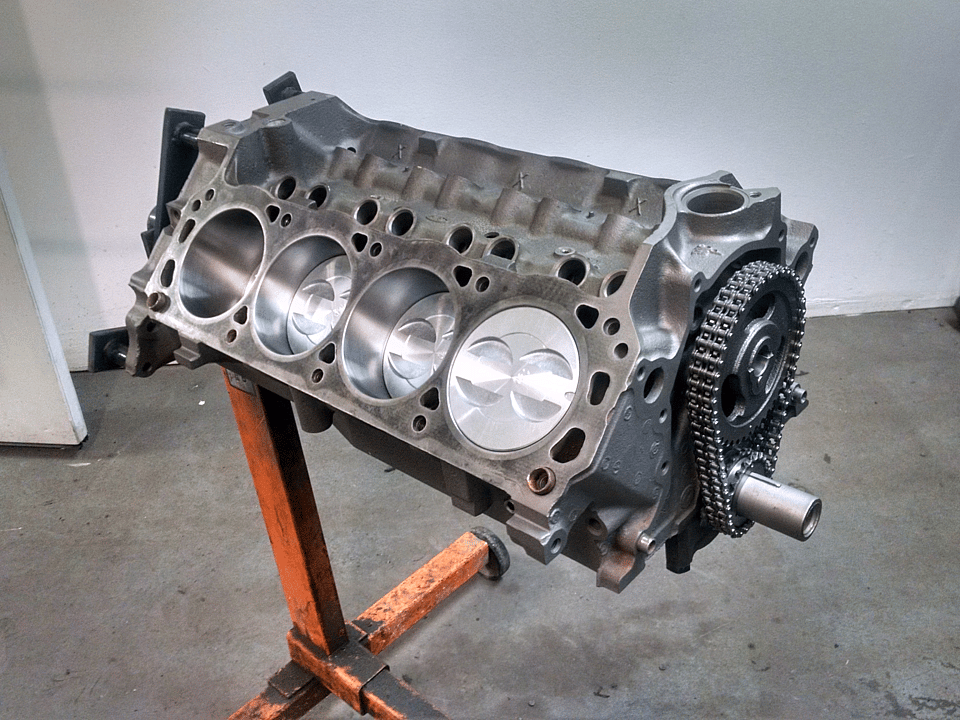

You're right, I still need to get the lifters, so I will probably try to give LMR a ring tomorrow.

It's been dark when I 've been getting home, so I decided to take a peek at the last order. After ripping out all the packing material, I finally got to all the parts..........wow, figured it would be much more.....impressive. The daughter asked what I had in the box......I just told her it was part of her college savings then gave her all the packing paper and told her she better make some impressive art out of it or she won't be able to attend college. It still puzzles me when my kids look at me like they would rather just try and cut the break lines of my truck.

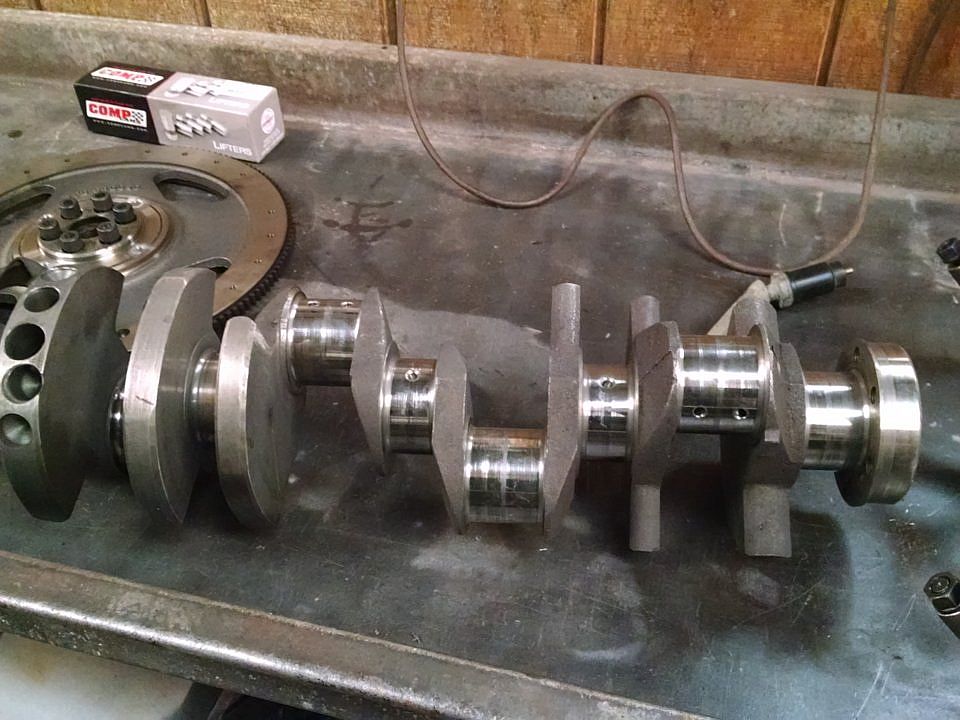

So here's the questions I have been mulling over. The flywheel for the 3550 looks pretty decent and is a "billet" piece and the pressure plate face looks great. I would love to send the disc and pressure plate back into the company to get tested and rebuilt (due to rear seal leakage). So I search for numbers and find exactly jack. Can anyone identify this clutch (I'm thinking Ram 9000 dual ceramic/organic)?

The picture is rough, but the discolored spots on both are oil I have not cleaned off.

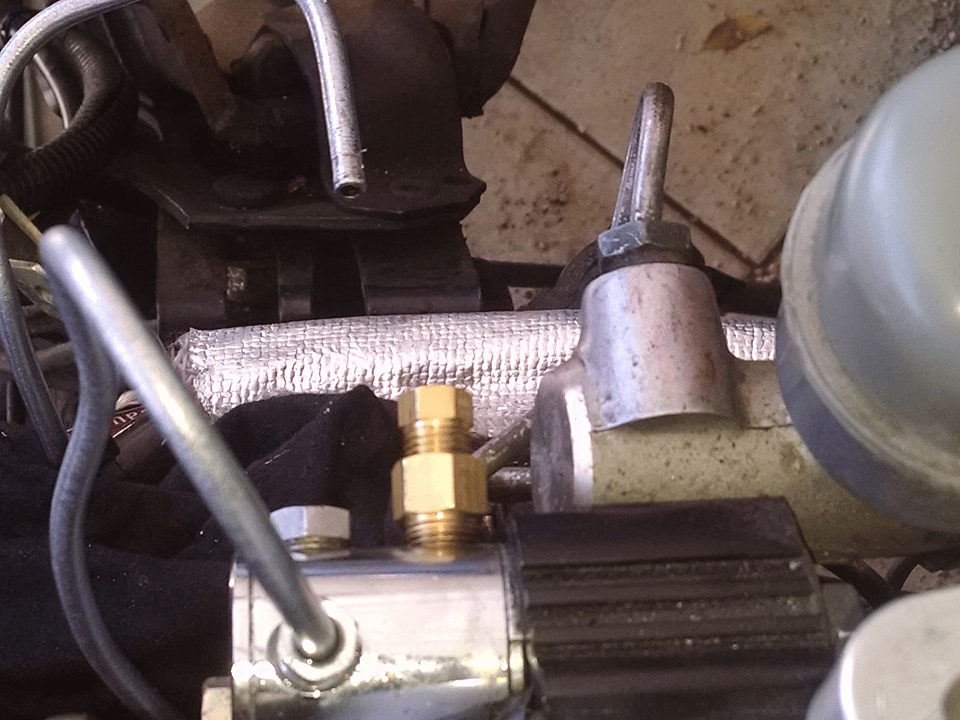

So here is question number two. If I do the Scott Rod inner panels it will only be to ease the distress I feel every time I look at the opening for the turbo. (The jackass that cut it decided he wanted to do it all over again.)

So if I decide to go with a black pair of the above, what is the best way to cut out the turbo opening? I killed a HF air saw doing the last cut and ended up with a cutting wheel, so the bulk would be tracing it out and neatly cutting it out.

You're right, I still need to get the lifters, so I will probably try to give LMR a ring tomorrow.

It's been dark when I 've been getting home, so I decided to take a peek at the last order. After ripping out all the packing material, I finally got to all the parts..........wow, figured it would be much more.....impressive. The daughter asked what I had in the box......I just told her it was part of her college savings then gave her all the packing paper and told her she better make some impressive art out of it or she won't be able to attend college. It still puzzles me when my kids look at me like they would rather just try and cut the break lines of my truck.

So here's the questions I have been mulling over. The flywheel for the 3550 looks pretty decent and is a "billet" piece and the pressure plate face looks great. I would love to send the disc and pressure plate back into the company to get tested and rebuilt (due to rear seal leakage). So I search for numbers and find exactly jack. Can anyone identify this clutch (I'm thinking Ram 9000 dual ceramic/organic)?

The picture is rough, but the discolored spots on both are oil I have not cleaned off.

So here is question number two. If I do the Scott Rod inner panels it will only be to ease the distress I feel every time I look at the opening for the turbo. (The jackass that cut it decided he wanted to do it all over again.)

So if I decide to go with a black pair of the above, what is the best way to cut out the turbo opening? I killed a HF air saw doing the last cut and ended up with a cutting wheel, so the bulk would be tracing it out and neatly cutting it out.