I have a 93 Mustang and the speedometer gauge recently appears to have failed. The needle stopped at 50mph and then after awhile it just slowly climbed until the needle maxed out on the gauge and then it stopped there even after I turned off the car. I'm trying to find a place where I can have the gauge rebuilt or repaired so I don't need to use a used gauge as a replacement. I'm wondering if anyone knows of a place where I can have this done.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rebuild Speedometer Gauge

- Thread starter Baron164

- Start date

-

Sponsors (?)

See Gauge Guys Home for speedo repair.

Some thoughts on how you got your current speedo problem...

Speedometer cable replacement for 87-93 Mustangs

Revised 1-Apr-2012 to clarify steps 11, 12, and 13, cable replacement inside the car.

How the speedometer works:

The indicator pointer has no direct connection to the speedo cable. It uses a drum with magnets on it to couple to the pointer. The drum turns and tries to twist the circular steel disk that is mounted on the pointer spindle. The magnetic force is all that connects the drum to the circular disk. There is very little clearance between the disk and drum, only a few thousands of an inch.

Lubrication warning

Use a graphite based lubricant for the speedo cable. It is available at most auto parts stores in a very small tube. Lubricate only the lower half of the cable. The reason for this is that if you use too much lubricant, it works its way up into the speedo head and gets between the rotating magnet and the disk. This causes the speedo to seize up and wring the indicator needle off the indicator spindle. You may be able to fix things up with non-flammable brake parts cleaner to clean the disk and magnet assembly. Plan on replacing the current cable and housing with a new cable and housing to prevent the excess lubricant from doing it all over again.

Speedometer cable replacement.

Note: All 89-93 cars have a VSS sensor even if they do not have cruise control. The 87-88 only have a VSS sensor if they have cruise control.

Speedo cable housing assembly without cruise control:

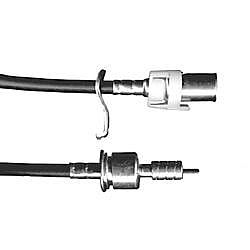

The VSS equipped cars have a speedo cable with a different fitting on the transmission end of the cable. It is the fitting on the LH side of the following picture.

Speedo cable housing assembly with cruise control

Preparation: if you are only going to replace the inner part of the speedo cable, get lots of newspaper or a painter’s drop cloth to cover the inside front of the car. About the time you have the dirty, oily speedo cable core all over your lap and the inside of the car, you will thank me for this suggestion.

Replacing only the inner cable: see steps 1- 6, 12, 13, 17-21

Replacing the housing and inner cable as an assembly: see steps 1-11, 13-21

Inside the car:

1.) Remove the shield around the steering column that covers the ignition switch & turn indicator switch.

2.) You now have access to the two screws that hold the lower part of the cluster housing in place. Remove them and place them in a zip bag.

3.) Use a stubby or an offset Philips screwdriver to remove the two screws on the top of the cluster housing. The screws are up close to the windshield, so they can be hard to get at.

4.) The cluster housing will now slide forward: depending on your particular car, you may or may not have to disconnect the wiring for the headlights, hazard lights, or cluster wiring. All of the wiring uses plastic connectors with plastic spring clips on them. To release the connectors, lift the plastic clips and pull straight back.

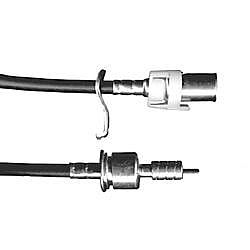

5.) The speedo cable is secured in the speedo head by a white plastic clip. Depress the clip or squeeze it and pull the cable out of the speedo head. This can be tricky, but it will come out if you have the white clip depressed enough.

Speedo head cable clip

Photos courtesy of Almost Stock

6.) With speedo cable removed from the speedo head, try twisting the cable end with your fingers. If it turns more than 1/4 turn, the cable may either be broken or you have damage at the other end where the cable mates to the VSS sensor or speedo pickup gear in the transmission.

Outside the car, replacing the cable housing assembly.

The following steps are necessary only if you plan on replacing the cable & cable housing assembly.

7.) If you are going to the replace the cable housing, the next step is important. Tie a study string or wire to the VSS sensor end of the cable housing. This string or wire is to be used to fish the cable housing back through the maze of wires that is under the dash. If all you are going to do is replace the inner cable, you can omit this step.

8.) Jack up the car, all 4 tires must be off the ground. Place jackstands under the car for safety.

9.) Locate the VSS sensor on the driver’s side of the transmission tailshaft housing. The speedo cable housing will be secured in the VSS sensor with a hairpin clip Do not remove the clip!!!: The hairpin clip stays in place. If you remove it, the odds are that you will not be able to get the cable to stay in place on re-installation. Pull firmly straight back on the cable housing and it will come out. A considerable amount of effort may be required to get the cable out of the VSS sensor, but it will pull out.

10.) Release the cable housing from the clips that secure it to the car body.

Inside the car:

11.) If all you are going to do is replace the inner cable, you can omit this step.

The housing assembly can then be pulled out and the fish string or wire can be removed from the old cable housing and secured to the new one.

12.) You can omit this step if you are replacing the cable & cable housing assembly.

The inner cable can be removed by pulling it out of the housing assembly. Watch out for the lubricant so that you don’t get it on the car’s interior.

13.) You can omit this step if you are replacing the cable & cable housing assembly.

Lubricate only the lower part of the new cable with speedometer lubricant or graphite. Don’t use too much lubricant, or it will work its way up into the speedo head unit and damage it. Thread the inner cable into the housing, turning it as you go. When you are all the way in with the new cable, it will engage the VSS sensor and stop turning.

Outside the car, replacing the cable housing assembly.

The following steps are necessary only if you plan on replacing the cable & cable housing assembly.

14.) Use the fish string or wire to feed the cable housing assembly through the dash wiring and out the cable hole in the firewall.

15.) Secure the cable in the body clips, making sure that the cable isn’t rubbing against the exhaust pipe.

16.) Push the cable housing assembly into the VSS sensor until it snaps in past the hairpin clip. Connect VSS wiring connector back to VSS sensor.

Inside the car:

17.) Push the cable housing back into the speedo head unit. You should be able to feel the white clip click into place.

18.) Reconnect all the wires & connectors on the speedo head unit.

19.) Re-install the cluster unit in the dash & tighten the 4 screws that hold it in place.

20.) Re-install the cover for the ignition switch & turn signal.

21.) If the car is up on jackstands, start the car, place it in gear & watch the speedo to see if it works OK. If you didn’t jack the car up, take a test drive[/URL].

Some thoughts on how you got your current speedo problem...

Speedometer cable replacement for 87-93 Mustangs

Revised 1-Apr-2012 to clarify steps 11, 12, and 13, cable replacement inside the car.

How the speedometer works:

The indicator pointer has no direct connection to the speedo cable. It uses a drum with magnets on it to couple to the pointer. The drum turns and tries to twist the circular steel disk that is mounted on the pointer spindle. The magnetic force is all that connects the drum to the circular disk. There is very little clearance between the disk and drum, only a few thousands of an inch.

Lubrication warning

Use a graphite based lubricant for the speedo cable. It is available at most auto parts stores in a very small tube. Lubricate only the lower half of the cable. The reason for this is that if you use too much lubricant, it works its way up into the speedo head and gets between the rotating magnet and the disk. This causes the speedo to seize up and wring the indicator needle off the indicator spindle. You may be able to fix things up with non-flammable brake parts cleaner to clean the disk and magnet assembly. Plan on replacing the current cable and housing with a new cable and housing to prevent the excess lubricant from doing it all over again.

Speedometer cable replacement.

Note: All 89-93 cars have a VSS sensor even if they do not have cruise control. The 87-88 only have a VSS sensor if they have cruise control.

Speedo cable housing assembly without cruise control:

The VSS equipped cars have a speedo cable with a different fitting on the transmission end of the cable. It is the fitting on the LH side of the following picture.

Speedo cable housing assembly with cruise control

Preparation: if you are only going to replace the inner part of the speedo cable, get lots of newspaper or a painter’s drop cloth to cover the inside front of the car. About the time you have the dirty, oily speedo cable core all over your lap and the inside of the car, you will thank me for this suggestion.

Replacing only the inner cable: see steps 1- 6, 12, 13, 17-21

Replacing the housing and inner cable as an assembly: see steps 1-11, 13-21

Inside the car:

1.) Remove the shield around the steering column that covers the ignition switch & turn indicator switch.

2.) You now have access to the two screws that hold the lower part of the cluster housing in place. Remove them and place them in a zip bag.

3.) Use a stubby or an offset Philips screwdriver to remove the two screws on the top of the cluster housing. The screws are up close to the windshield, so they can be hard to get at.

4.) The cluster housing will now slide forward: depending on your particular car, you may or may not have to disconnect the wiring for the headlights, hazard lights, or cluster wiring. All of the wiring uses plastic connectors with plastic spring clips on them. To release the connectors, lift the plastic clips and pull straight back.

5.) The speedo cable is secured in the speedo head by a white plastic clip. Depress the clip or squeeze it and pull the cable out of the speedo head. This can be tricky, but it will come out if you have the white clip depressed enough.

Speedo head cable clip

Photos courtesy of Almost Stock

6.) With speedo cable removed from the speedo head, try twisting the cable end with your fingers. If it turns more than 1/4 turn, the cable may either be broken or you have damage at the other end where the cable mates to the VSS sensor or speedo pickup gear in the transmission.

Outside the car, replacing the cable housing assembly.

The following steps are necessary only if you plan on replacing the cable & cable housing assembly.

7.) If you are going to the replace the cable housing, the next step is important. Tie a study string or wire to the VSS sensor end of the cable housing. This string or wire is to be used to fish the cable housing back through the maze of wires that is under the dash. If all you are going to do is replace the inner cable, you can omit this step.

8.) Jack up the car, all 4 tires must be off the ground. Place jackstands under the car for safety.

9.) Locate the VSS sensor on the driver’s side of the transmission tailshaft housing. The speedo cable housing will be secured in the VSS sensor with a hairpin clip Do not remove the clip!!!: The hairpin clip stays in place. If you remove it, the odds are that you will not be able to get the cable to stay in place on re-installation. Pull firmly straight back on the cable housing and it will come out. A considerable amount of effort may be required to get the cable out of the VSS sensor, but it will pull out.

10.) Release the cable housing from the clips that secure it to the car body.

Inside the car:

11.) If all you are going to do is replace the inner cable, you can omit this step.

The housing assembly can then be pulled out and the fish string or wire can be removed from the old cable housing and secured to the new one.

12.) You can omit this step if you are replacing the cable & cable housing assembly.

The inner cable can be removed by pulling it out of the housing assembly. Watch out for the lubricant so that you don’t get it on the car’s interior.

13.) You can omit this step if you are replacing the cable & cable housing assembly.

Lubricate only the lower part of the new cable with speedometer lubricant or graphite. Don’t use too much lubricant, or it will work its way up into the speedo head unit and damage it. Thread the inner cable into the housing, turning it as you go. When you are all the way in with the new cable, it will engage the VSS sensor and stop turning.

Outside the car, replacing the cable housing assembly.

The following steps are necessary only if you plan on replacing the cable & cable housing assembly.

14.) Use the fish string or wire to feed the cable housing assembly through the dash wiring and out the cable hole in the firewall.

15.) Secure the cable in the body clips, making sure that the cable isn’t rubbing against the exhaust pipe.

16.) Push the cable housing assembly into the VSS sensor until it snaps in past the hairpin clip. Connect VSS wiring connector back to VSS sensor.

Inside the car:

17.) Push the cable housing back into the speedo head unit. You should be able to feel the white clip click into place.

18.) Reconnect all the wires & connectors on the speedo head unit.

19.) Re-install the cluster unit in the dash & tighten the 4 screws that hold it in place.

20.) Re-install the cover for the ignition switch & turn signal.

21.) If the car is up on jackstands, start the car, place it in gear & watch the speedo to see if it works OK. If you didn’t jack the car up, take a test drive[/URL].

Last edited:

Thanks, I'm going to pull the cluster out this weekend and see if I can figure it out before deciding if I want to ship it out. I replaced the cable and sensor early last year and it was fine the rest of the year. It's been sitting in the garage for about 6 months so I don't see how work done almost a year ago would be the culprit. The speedometer in this car has been an issue for years so I'm not entirely surprised if the gauge has just up and failed on me.

So I thought I'd update this thread. I've pulled the cluster apart. I've taken the individual pieces of the speedometer and they all appear to work independently. Just not when they are in the car. I took the back piece where the speedometer cable connects and verified that the cable does in fact spin the magnet. And then I have it assembled when the magnet spins it does spin the needle. So everything works, when it's not in car. The end piece where the cable attaches does squeal a good amount. I sprayed it down with WD-40 and that helped a bit with the squealing but didn't affect anything else. I'm going to test it out some more tomorrow and see if I can figure out anything. But at this point I'm thinking of just ordering another speedometer off ebay.

So after some further testing I confirmed that all though the magnet is spinning it just isn't grabbing the dish when it's in the dashboard. Doesn't make any sense to me why that is but I ordered an entire cluster off eBay that will hopefully resolve this issue for me. I should have that by the end of the week. Provided the speedo and everything works in the new cluster I'll just put in the new cluster and use the old one for parts. All I'll have to do is change the odometer to match my old one.

Well I received the "new" cluster yesterday, mine was still in better shape so I decided to tear down the old one and use it for parts. I was able to get my speedometer working again. The needle is a little shaky under 20mph but after that is fine. The "new" speedometer head was squealing so I lubed it with gun oil which I read works pretty well for those. So far so good. I put it back together but may need to take it apart again and apply some more lubrication to the speedometer head. I'm concerned that it might drip out the end. The calibration is still off, for example when it says I'm doing 80 I'm really only doing 70. I'm fairly certain that's the speedo gear though which I plan on ordering today and putting next week and then hopefully I'll have a properly working speedometer in this car for first time since I bought it.

So the continued saga of my speedometer problems. The speedometer head started squealing again and got progressively worse. I spent most of this past Sunday messing around with it. I had torn it down Friday night and practically submerged the head in 3in1 oil. When I tested Sunday morning it was still squealing. After some cleaning/testing/oiling/ I eventually cleaned off the entire head with brake cleaner and just put a little oil on the screw shaft under the magnet (which I had already previously oiled and cleaned off) and then miraculously the squealing was gone perfectly quiet. I put the head back on the speedometer and reassembled the cluster and put it back in the car for more testing.

And now the needle is jumping around like a jack rabbit just like it was last year before I replaced the cable and started down this cluster f@#& highway. During my testing I was installing and removing the speedometer head from the car several times and the cable was giving me some difficulty getting it to clip onto the speedometer head so I'm not sure if I managed to pull the cable and put a kink in it or what. I went up and down through the cable and tried to loosen it and make sure there were no kinks. The jumping got a little better after that but it's still crap. When just rolling under 5mph the needle will bounce up to 30mph. When I'm at speed if I'm doing an estimate 60mph the needle will bounce back and forth between 55 and 65mph.I tried cleaning off the upper end of the cable with brake cleaner and then adding more lubrication to it and neither appeared to resolve the issue. I eventually got fed up with it and had to quit.

I'm already planning on ordering a new drive gear for the lower end of the cable so now I'm wondering if I should also order another cable. It's starting to drive me insane how the smallest things cause the biggest headaches.

And now the needle is jumping around like a jack rabbit just like it was last year before I replaced the cable and started down this cluster f@#& highway. During my testing I was installing and removing the speedometer head from the car several times and the cable was giving me some difficulty getting it to clip onto the speedometer head so I'm not sure if I managed to pull the cable and put a kink in it or what. I went up and down through the cable and tried to loosen it and make sure there were no kinks. The jumping got a little better after that but it's still crap. When just rolling under 5mph the needle will bounce up to 30mph. When I'm at speed if I'm doing an estimate 60mph the needle will bounce back and forth between 55 and 65mph.I tried cleaning off the upper end of the cable with brake cleaner and then adding more lubrication to it and neither appeared to resolve the issue. I eventually got fed up with it and had to quit.

I'm already planning on ordering a new drive gear for the lower end of the cable so now I'm wondering if I should also order another cable. It's starting to drive me insane how the smallest things cause the biggest headaches.

As I stated before oil between the disk/ drum and the magnets will cause the problem you are seeing. Carefully clean the disk/drum and magnets to remove all traces of oil.

The drum and magnet do not have any oil on them. I made sure they were clean when I put it back together, gave them a good cleaning with brake cleaner.

Well I replaced the cable and put in a new 19tooth gear to replace the old 16tooth gear and everything seems to be working. Only issue now is that instead of the needle being 10-12-mph too fast at highway speed it's about 5mph too slow so I think I'll have to put in a 18 tooth gear to correct that. But at least the needle isn't bouncing anymore.

Similar threads

- Replies

- 2

- Views

- 600

Electrical

Gauge cluster

- Replies

- 7

- Views

- 1K

Interior and Upholstery

Need Speedometer Help

- Replies

- 42

- Views

- 5K

- Replies

- 2

- Views

- 266

- Replies

- 5

- Views

- 853