- Dec 19, 2010

- 5,719

- 4,238

- 224

Had to blow the dust off of this one.:no:

This update starts last Thursday.

Sometime in my past years I bit on something that cracked tooth 19. I had no idea at the time I cracked tooth 19, but given enough time, it managed to make itself obvious that there was something wrong. It took four dentists and 8 months before one of them, (dentist#3) actually found the crack and declared tooth 19 DOA. The prognosis determined that it be removed,.......surgically removed.

Last Thursday, dentist #4 did just that. Now I'm not a fan of the dentist, and when the words extraction come out of one of their mouths, the words sedation come back out of mine. I was anesthetized. Put to sleep.

When I woke up, There was a gaping hole back there where dead tooth 19 had once lived, and I was loopy. This brings me around to what all this has to do with working on the car. Being loopy, w/ a completely numb left side of my face was not conducive to working on it. It was hotter than hell, and I was tired, so I did the only thing that a person recovering from a tooth19-N-dectomy could do....

I got in my truck, and took my 75/25 welding gas bottle in for a recharge.

I drive real good when chemically "soothed" so as to cope w/ getting one of your molars cut out of your head.

On Friday I was much better.

Previously, I said that the old fuel tank setup was due for replacement. I had ordered a tube type fuel level sending unit rated at 70/10 ohms. Additionally, I got some steel weld fittings for the supply, vent, and return lines.

The sending unit is 8" long, and the tank is about 9.5" deep. That meant I had to recess the thing so that it would be in the bottom of the tank. I welded the hole closed where the old sender used to be, and welded the fittings in the top, and bottom of the tank.

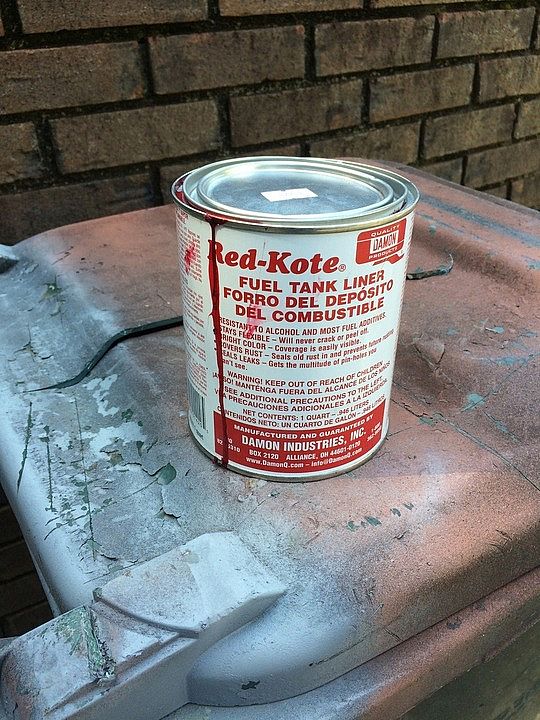

All of this welding brings about the issue of leaks. I can't say whether or not I have any,..I don't give the tank a chance to leak. I pour in some tank sealer, and tip the tank around until I'm sure that I have coated the weld areas so any potential pinholes will be sealed forever.

You can just see the red goo when looking through the filler neck hole. That is the sending unit, and the tube on the bottom is running to the center of the tank, so fuel will be picked up from of the middle, as opposed to the side where the fitting is located. I don't know whether that will make a difference, but it made sense to me at the time.

After that, I relocated the fuel pump and filters to the front of the tank, as opposed to the rear where it was before.

Then came Saturday. and Sunday.

Then the following Friday, Saturday, Sunday, and today.

Spent in hell. Trying to make the rear facade move from "unfinished", to "finished"

It's still not done.

Despite my feeble attempt at making sure the welds were properly ground, and matched up so as to have a smooth body line, by the time filler started to get slathered on, high spots started rearing their head. All along the bulkhead weld seam, where you couldn't simply peck the high spot down. I had to grind the high spot, which in turn turned the surrounding sheet metal into toilet paper. You can see one of them poking his pimply ass through on the lower quarter, right below the previously hacked one, barely covered in filler.

I had no choice at this point, I had to keep at it. Everytime I'd butcher a high spot, a new one would show right back up. The real frustrating part of all of this is that it would get so close, and then there it would be,......Mr. Shiner, threatening to poke it's head back through if I made one more stoke w/ the samding block.

I gave up. I'm wrecked.

All of this "body work" done mostly by hand. Despite the fact that I went Saturday, and spent almost 200.00 on air tools from Harbor Freight, the fact that they were harbor Freight air tools make them pretty useless.

The Air file?.......It's an air hog, and requires so much CFM, it literally dies after one minute of use. Supposed to consume 6 CFM @ 90 PSI, My compressor didn't even turn back on before that flaming piece of crap would just stop.

Harbor freight sand paper? It garbage. The 36 grit stuff would tear in half sometimes immediately.

It wasn't all bad, The Jitterbug worked like it was supposed to, but again, the paper. This time the stuff didn't tear, it just didn't fit. Every piece had to have 1/4" cut off of it everytime. I don't know whether the sander was sized wrong, or the paper, but it was a pain in the ass just the same.

I bought a whole bunch of other "consumables" to finish my sanding/grinding/cutting. I expect they'll be stellar performers as well.

So, frustrated, covered in white dust as of this minute, covered in sweat, and smelling like 3 goats, I' manage to stop at this point.

But,....wait.....I wonder how hard it would be to scrape off the paint with a single edge razor blade?

I tell ya, I'm like a dog. I get distracted in a heartbeat. I can say that scraping the paint off that quarter w/ a razorblade was the easiest thing I've done in the last 5 days though.

Then,.....because I'm as tired as you are of looking at the same damn thing,.....I jerry rigged the tail light lenses in place.

This is supposed to be the money shot. But as with everything I do in this build, there always seems to be a thunderstorm, raining on my parade.

The tail lights are wrong. The left one is 1/4" deeper than the right one. How in the hell this happened is beyond me, and short of completely cutting the rear panel off that the tail lights bolt to and redoing it, that is the only way to fix the discrepancy. I'm so ****ed right now, you don't even know.

Yeah, the trunk is sealed shut in filler. I'll cut it back out when I get everything finished. Ironic actually, I was so worried about making sure that the trunk will completely blend into the rear facade, and now I have a wonky assed tail light instead.

Despite the tail light issue it looks fantastic, Mike. Can't wait to see it in paint!