Oh, the last pic is the coupe stranded out in the rain. Luckily, no hail. Tropical storm Bill was a bust.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Build Thread The Hoopty Chronicles - New House, New garage, New Car?

- Thread starter hoopty5.0

- Start date

-

Sponsors (?)

Yeah, but it's being driven. Beats letting it rot, no?Leaving the notch out in the rain. If I could "dislike" a post I would.

Of course but it's still a sad sight. At least it's a driver. If I ever could I'd have a huge garage big enough for all my vehicles and they'd all be tucked in at night out of the elements. I didn't get the part of my wish list that had a 3 car garage and a detached shop.

I am steadily working towards that goal. Maybe in another 5 years I will have a piece of property and a barn.

- Dec 19, 2010

- 5,719

- 4,238

- 224

Rain is a lot easier on the car than sunshine. Being parked in the sun will do more damage to the car than leaving it in the rain.Leaving the notch out in the rain. If I could "dislike" a post I would.

Rain, moisture, humidity etc = rust and rot of body and floor and is hell on your electrical system. Sun damages clear coat, fades interior, possible cracked dash over a long period of time. So I guess they both suck.Rain is a lot easier on the car than sunshine. Being parked in the sun will do more damage to the car than leaving it in the rain.

http://www.toonutsracing.com/smf/ind...?topic=1421.15

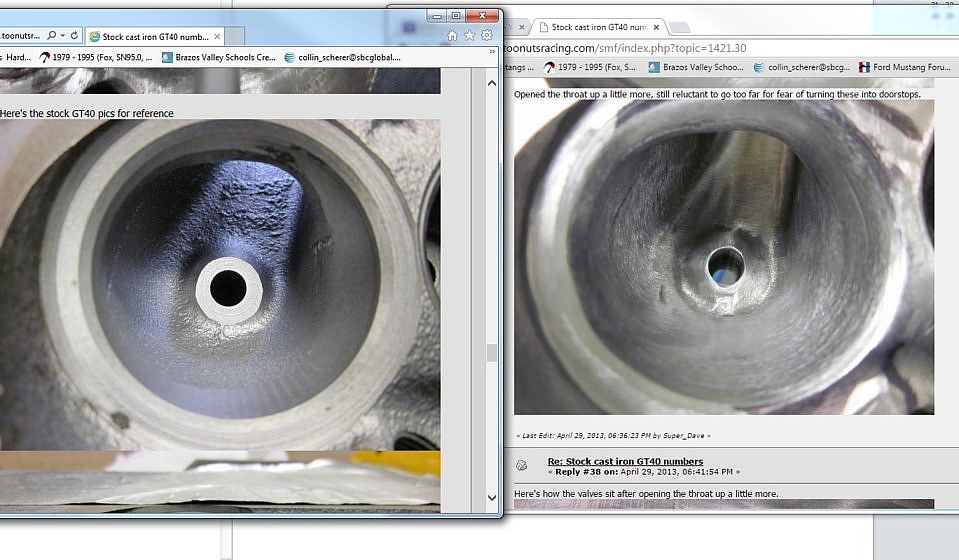

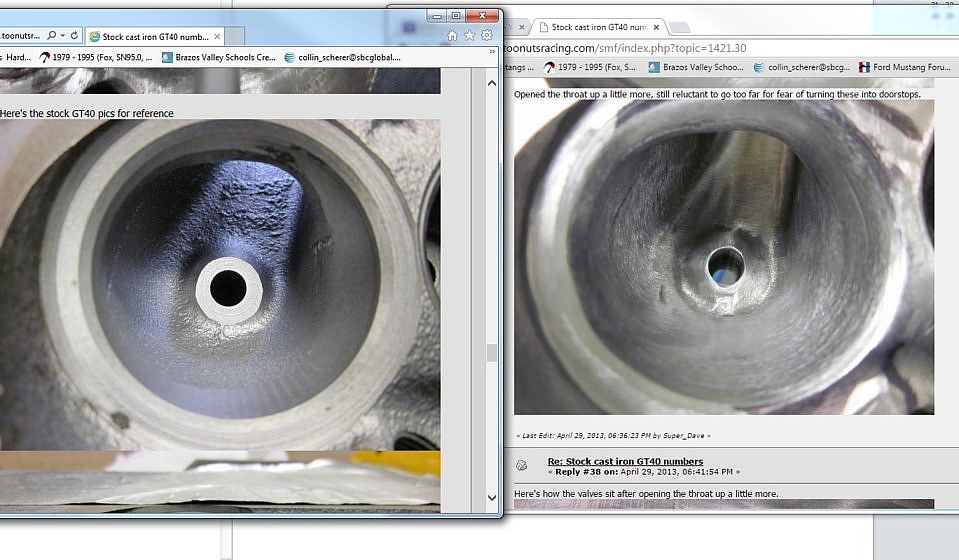

This is far and away the best thread I've read on porting with flow results along the way. I also got a side by side pic of his intake bowl/throat and a stocker. pretty cool. I have a lot of work to do it looks like.

This is far and away the best thread I've read on porting with flow results along the way. I also got a side by side pic of his intake bowl/throat and a stocker. pretty cool. I have a lot of work to do it looks like.

Looks like the guy blended the hard edges of the valve seat. You can see them in the stock pic on the left and the look like they're gone in the pic on the right. I don't think that's a good idea. There are a lot of similarities that I learned while surfing for 25 years between hydrodynamics and aerodynamics in regards to airfoil. I know airfoil is more about airplane wings & sails but there are similarities. Air, like water, likes to follow and stick to curves which will slow it down (longer distance traveled over the surface) as opposed to hard edges which can increase air flow. There's a lot more to it than that but that's the short and sweet of it. So what I'm trying to say is you want those hard edges in the pic on the left, not only for an air tight valve seat but to increase air velocity when the valve opens.

Forgot to mention this was before the seats were cut for a valve job.Looks like the guy blended the hard edges of the valve seat. You can see them in the stock pic on the left and the look like they're gone in the pic on the right. I don't think that's a good idea. There are a lot of similarities that I learned while surfing for 25 years between hydrodynamics and aerodynamics in regards to airfoil. I know airfoil is more about airplane wings & sails but there are similarities. Air, like water, likes to follow and stick to curves which will slow it down (longer distance traveled over the surface) as opposed to hard edges which can increase air flow. There's a lot more to it than that but that's the short and sweet of it. So what I'm trying to say is you want those hard edges in the pic on the left, not only for an air tight valve seat but to increase air velocity when the valve opens.

Looks like the guy removed a fair amount of material on the inside and took the valve stem bump down quite a bit too. Did he flow the heads before and after?

Well, not before as that data is pretty commonly accepted (in the 190cfm range) but after was 240cfm and then 250 after the multi-angle valve job.

What's even more impressive is on another thread, a guy had his TW170s flowed and they were outperformed by these GT40s. The guy said he ended up making 338 whp with his GT40s. LOL. I remember Nik made 336 with his TEA 205s, albeit with a very mild cam.

So, if anything, if you do this yourself and don't count your time as money, it CAN be well worth it to port old iron heads IF you spend the time to learn and do it the right way.

***Edit - also goes to show how well matched parts can be made to perform very well.

What's even more impressive is on another thread, a guy had his TW170s flowed and they were outperformed by these GT40s. The guy said he ended up making 338 whp with his GT40s. LOL. I remember Nik made 336 with his TEA 205s, albeit with a very mild cam.

So, if anything, if you do this yourself and don't count your time as money, it CAN be well worth it to port old iron heads IF you spend the time to learn and do it the right way.

***Edit - also goes to show how well matched parts can be made to perform very well.

The cutaway pics on that site are priceless when doing what you're doing. You can clearly see how close the water jackets are to the ports and where there is not much you can remove in some areas and lots in others. Looks like you nearly have all the info you need to do a decent job.

The only piece I can't find is how much to work over the short side radius, but there is enough info in there to piece it together with some scaling and measuring.

2 things -

There's a machine shop by the office with a flow bench that will flow 1 intake/exhaust for $30. For whatever reason, I figured it would be a ton more. So, sounds like I'll be making a few trips over there as I move through this project.

Also, I bought a stud mount conversion and a set of billet 1.6 RRs for $110 shipped today. Can't argue with that.

There's a machine shop by the office with a flow bench that will flow 1 intake/exhaust for $30. For whatever reason, I figured it would be a ton more. So, sounds like I'll be making a few trips over there as I move through this project.

Also, I bought a stud mount conversion and a set of billet 1.6 RRs for $110 shipped today. Can't argue with that.

I worked the SSR on an intake runner last night and cleaned up the exhaust valve guides some. Dropping the head off at lunch to get flowed. Cross your fingers for 6-8% gain. That's my guess at least.

- Dec 19, 2010

- 5,719

- 4,238

- 224

I worked the SSR on an intake runner last night and cleaned up the exhaust valve guides some. Dropping the head off at lunch to get flowed. Cross your fingers for 6-8% gain. That's my guess at least.

If other folks are jumping as high as 240-250cfm from 190, why do you only expect 6-8%? No sarcasm, but my math says you should get more. Am I missing something?

haha yeah, about 40 more hours of labor

*edit - not on that one runner, but my point is I have not spent any time on the intake runners yet to get a ton more flow. I have only done the most basic items which is why I am not expecting more.

*edit - not on that one runner, but my point is I have not spent any time on the intake runners yet to get a ton more flow. I have only done the most basic items which is why I am not expecting more.

Similar threads

- Replies

- 110

- Views

- 9K

- Replies

- 19

- Views

- 2K

- Replies

- 6

- Views

- 1K

- Replies

- 18

- Views

- 2K

Progress Thread

H/C Swap Problems/Ideas

- Replies

- 3

- Views

- 375