You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Build Thread Dusty ain't gettin' worked on...

- Thread starter 90sickfox

- Start date

-

Sponsors (?)

- Mar 2, 2015

- 6,821

- 5,858

- 203

I got an early chance to run out to the JY. I was home sick...but the JY is right up the road.

Just to let anyone know in Southern Maryland.... There are two v8 explorers at Hughsville Scrap on Route 5. I'm going out tomorrow ( after I medicate myself ) and getting a cam sensor off one of them.

I was surprised to see the same one I took the fuel rail off of still sitting out there.

I did get an EDIS8 off of a 94 Crown Victoria at Harris Scrap in Hollywood, MD.

Pretty good day....can't talk...and feel like hell...but I got some parts....and a quart of Southern Maryland Apple Pie.

Just to let anyone know in Southern Maryland.... There are two v8 explorers at Hughsville Scrap on Route 5. I'm going out tomorrow ( after I medicate myself ) and getting a cam sensor off one of them.

I was surprised to see the same one I took the fuel rail off of still sitting out there.

I did get an EDIS8 off of a 94 Crown Victoria at Harris Scrap in Hollywood, MD.

Pretty good day....can't talk...and feel like hell...but I got some parts....and a quart of Southern Maryland Apple Pie.

- Mar 2, 2015

- 6,821

- 5,858

- 203

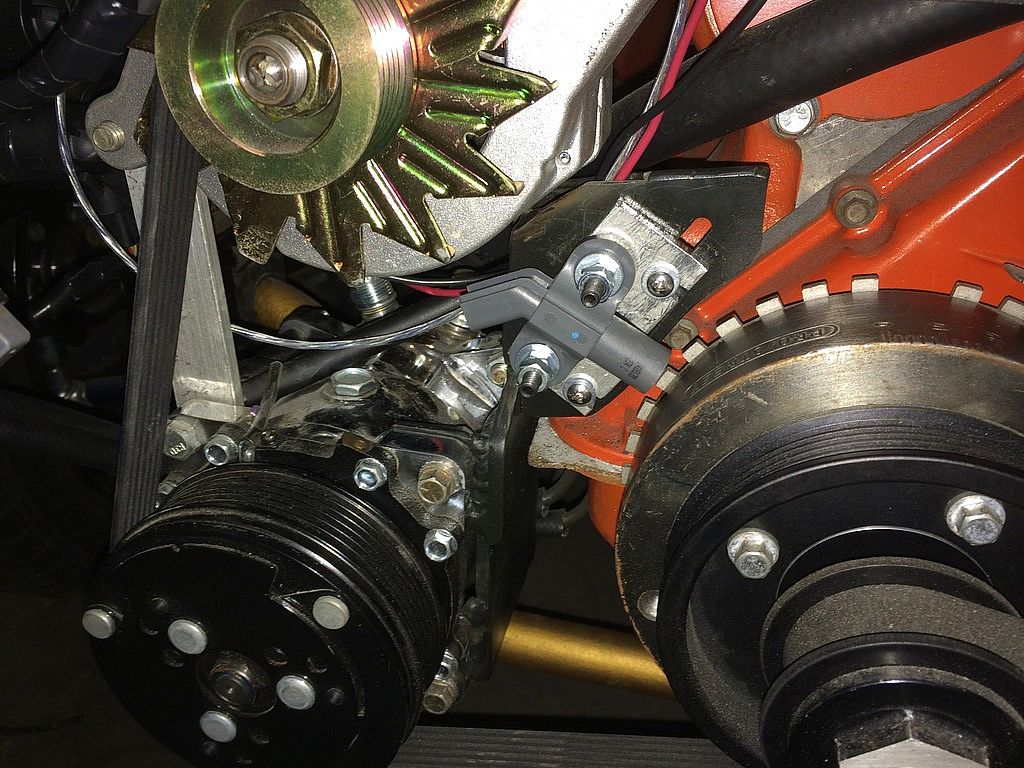

I've been staring at this motor tryin' to figure out where I can put these coil packs. There's so much crap real estate is almost non existent.

Guess I could move the battery to the trunk. I didn't want to do that....but.... I'll think on it a little more.

I don't think I want them sitting where they do on the explorers. I'll think of something.

Guess I could move the battery to the trunk. I didn't want to do that....but.... I'll think on it a little more.

I don't think I want them sitting where they do on the explorers. I'll think of something.

- Mar 2, 2015

- 6,821

- 5,858

- 203

I don't know what people think sometimes... The first can sensor I pulled looked like this...

Guess someone thought it was a good idea to grind on the shaft...

The other candidate turned out a lot better...

I've got lots of cleaning to do. Apparently, the coils and can sensor were recently replaced before the truck sat with the hood open. Guess I should've closed it when I pulled the fuel rail months ago.

Guess someone thought it was a good idea to grind on the shaft...

The other candidate turned out a lot better...

I've got lots of cleaning to do. Apparently, the coils and can sensor were recently replaced before the truck sat with the hood open. Guess I should've closed it when I pulled the fuel rail months ago.

- Mar 2, 2015

- 6,821

- 5,858

- 203

That thing just sits there and drives the oil pump. The cam sensor isn't used for the EDIS8 swap.

DIYautotune sells a trigger wheel for ford balancers for the low- low price of 26.99. The crank sensor will be bought new 25.99 from RockAuto.

All I've got to do then is wire it up and fab a bracket for the crank sensor. The sensor is placed exactly 5 notches after the gap in the trigger wheel. The wheel is 36- 1 and pre balanced. Just drill the premade slots out for the four bolt crank pulley and....space out all the accessories to match the pulleys new position.

Badda bing...Badda boom !!! precise timing...rock solid timing curve =

Not bad for 40 bucks worth of JY parts....and 50- 60 bucks of brand new shiny parts.

Right now, I'm not experiencing any timing issues. My timing depicts what MS commands it to be through the rpm curve....still haven't been above 5 grand.

With mid to late 90s parts getting harder and harder to find I figured now would be as good a time as any to grab up some things. I have a bad habit of collecting for future projects. Seems like so much stuff that I wanted has been discontinued or has become super hard to find.

My oil leaks have been fixed.... so I'll continue to use high temp permatex on oil fittings...and Quick Steel has fixed my oil pan.

DIYautotune sells a trigger wheel for ford balancers for the low- low price of 26.99. The crank sensor will be bought new 25.99 from RockAuto.

All I've got to do then is wire it up and fab a bracket for the crank sensor. The sensor is placed exactly 5 notches after the gap in the trigger wheel. The wheel is 36- 1 and pre balanced. Just drill the premade slots out for the four bolt crank pulley and....space out all the accessories to match the pulleys new position.

Badda bing...Badda boom !!! precise timing...rock solid timing curve =

Not bad for 40 bucks worth of JY parts....and 50- 60 bucks of brand new shiny parts.

Right now, I'm not experiencing any timing issues. My timing depicts what MS commands it to be through the rpm curve....still haven't been above 5 grand.

With mid to late 90s parts getting harder and harder to find I figured now would be as good a time as any to grab up some things. I have a bad habit of collecting for future projects. Seems like so much stuff that I wanted has been discontinued or has become super hard to find.

My oil leaks have been fixed.... so I'll continue to use high temp permatex on oil fittings...and Quick Steel has fixed my oil pan.

@Boosted92LX -

Here is some good edis swap info

Sounds like you've had a good score at the junkyard,won't be to much longer till the upgrade is done how much stuff do you have left . Before a test drive?

how much stuff do you have left . Before a test drive?

-I was eyeballing a 99 5.0 explorer a couple of wknds ago that hasn't been touched yet-but it was cold and I had minimal tools to be able to rob the top end lol

Here is some good edis swap info

That thing just sits there and drives the oil pump. The cam sensor isn't used for the EDIS8 swap.

DIYautotune sells a trigger wheel for ford balancers for the low- low price of 26.99. The crank sensor will be bought new 25.99 from RockAuto.

All I've got to do then is wire it up and fab a bracket for the crank sensor. The sensor is placed exactly 5 notches after the gap in the trigger wheel. The wheel is 36- 1 and pre balanced. Just drill the premade slots out for the four bolt crank pulley and....space out all the accessories to match the pulleys new position.

Badda bing...Badda boom !!! precise timing...rock solid timing curve =

Not bad for 40 bucks worth of JY parts....and 50- 60 bucks of brand new shiny parts.

Right now, I'm not experiencing any timing issues. My timing depicts what MS commands it to be through the rpm curve....still haven't been above 5 grand.

With mid to late 90s parts getting harder and harder to find I figured now would be as good a time as any to grab up some things. I have a bad habit of collecting for future projects. Seems like so much stuff that I wanted has been discontinued or has become super hard to find.

My oil leaks have been fixed.... so I'll continue to use high temp permatex on oil fittings...and Quick Steel has fixed my oil pan.

Sounds like you've had a good score at the junkyard,won't be to much longer till the upgrade is done

-I was eyeballing a 99 5.0 explorer a couple of wknds ago that hasn't been touched yet-but it was cold and I had minimal tools to be able to rob the top end lol

- Mar 2, 2015

- 6,821

- 5,858

- 203

@Boosted92LX I understand. I should have pulled the intakes and grabbed the heads, too. Just couldn't bring myself to do it. The coil packs and cam sensor are easy....just one 1/2 inch deep socket....3 inch extension...and a 3/8 ratchet.

Fighting rusty manifold bolts isn't at the top of my list. Better to do it in the cold and avoid ticks, spiders, and snakes.

Fighting rusty manifold bolts isn't at the top of my list. Better to do it in the cold and avoid ticks, spiders, and snakes.

- Mar 2, 2015

- 6,821

- 5,858

- 203

@RaggedGT the crank trigger wheel is the one made by diyautotune.com { I'm not sure of the actual measurement } I think its 6.5 inches but I could be wrong. I do know that the stock explorer crank sensor will work. Its in a write up on DIYautotunes site.

edit ; The crank wheel is 6 3/4 inches ( checked the site )

edit ; The crank wheel is 6 3/4 inches ( checked the site )

Last edited:

- Mar 2, 2015

- 6,821

- 5,858

- 203

Happy New Year !!!!!

I absolutely did mix you guys up @RaggedGT and @Boosted92LX ..... My brain was a Lil' mixed up, too. Lol

I absolutely did mix you guys up @RaggedGT and @Boosted92LX ..... My brain was a Lil' mixed up, too. Lol

I used the smaller one on my balancer,..( which coincidently is the same as your balancer,....i put a sbf balancer on my engine)Sweet! Tanx mang!

@90sickfox So, if you don't mind, a few questions.

On the trigger wheel, did you get the 8" unit, or is the 6 1/2" wheel the one needed??

And a stock replacement sensor from an explorer along with pigtail will work??

I'm sure I'll have more questions..

The bigger toothed wheel was gonna hit stuff, and the smaller one hangs about a sniglet off of the balancer and looks way better. I have the big one too,...but it's just hanging on a nail.

- Dec 19, 2010

- 5,719

- 4,238

- 224

Sorry if i missed it, but did you bolt it on after machining? How is it fastened?

I drilled and tapped the balancer from behind. I didn't want it to push the pulleys out of alignment. It meant having the center of that trigger wheel completely cut away so the balancer snout (I had no counter weight, I'm zero balanced internal) would stick through. This is the hardest part of the whole deal.....trying to decide to mount the thing up front and deal w/ belt misalignment, or get creative, and mount that thing behind. (You should see how bad it looks,....It's literally an OMG.)Sorry if i missed it, but did you bolt it on after machining? How is it fastened?

- Mar 2, 2015

- 6,821

- 5,858

- 203

Do you know what this means ?

The car runs decent but there's a lot more tuning to do.....and a lot to buy. This is a huge milestone for me. Dusty actually moves, stops, and turns.

Everything else works great ! Brakes are wonderful and it drives and stops under its own power.

Its come a long way. Its a shame I've got to wait till it gets warmer to finish the body work.

The car runs decent but there's a lot more tuning to do.....and a lot to buy. This is a huge milestone for me. Dusty actually moves, stops, and turns.

Everything else works great ! Brakes are wonderful and it drives and stops under its own power.

Its come a long way. Its a shame I've got to wait till it gets warmer to finish the body work.

Last edited:

Do you know what this means ?

The car runs decent but there's a lot more tuning to do.....and a lot to buy. This is a huge milestone for me. Dusty actually moves, stops, and turns.

Everything else works great ! Brakes are wonderful and it drives and stops under its own power.

Its come a long way. Its a shame I've got to till it gets warmer to finich the body work.

We're all coming around,..It's kinda cool actually...several simultaneous builds all starting to show what we all have gotten filthy, hot, sweaty, cut, broken and discouraged for years straight sometimes for in the first place.

Good job, congrats.

- Mar 2, 2015

- 6,821

- 5,858

- 203

I've been pulling my hair out trying to make a restrictor for my turbo. My old nitrous jets seem to be a different angle than the -4 AN line that came from on3. My jets were in nozzles that -3 AN line screwed on. I can easily machine the brass 90° on3 sent to accept a .063 nitrous jet....but....if the line doesn't seal I'm screwed.

I could always just order one from on3...but I want to make my own....wah wah waaaah ! Lol

I'm not actually pulling my hair out....nor am I actually crying. I think I'm getting used to this. ( sigh of relief )

Someone already thought of this...all I've got to do is shell out a little cash.

I could always just order one from on3...but I want to make my own....wah wah waaaah ! Lol

I'm not actually pulling my hair out....nor am I actually crying. I think I'm getting used to this. ( sigh of relief )

Someone already thought of this...all I've got to do is shell out a little cash.

- Mar 2, 2015

- 6,821

- 5,858

- 203

Thought I'd add a little more to the story.

I pulled my laptop out and hooked up to the megasquirt...started the car and it would not idle without playing with the throttle. I set my required fuel from 10.3 to eventually 9.5 and it idles fine. Take it out to drive through my neighborhood, which includes a steep down grade. The clutch goes in and the other big foot presses on the brake pedal. When the car stopped it promptly cut off...fired her up and she drove forward some more ( on the down grade )...I hit the brakes and she cut off again...wtf. At the second time I was looking at the fuel pressure gauge and caught it fluctuate...which made me look at the gas gauge. Guess what I saw.....you're correct...I was out of gas. Threw her in reverse and slowly reversed back to my driveway. lol.

A trip to the gas station to fill the can with 93 and Dusty was purring again. Its amazing what fuel can do to a vehicle. madmike1157 was on my mind the whole time. There's so much excitement going on when you start out on a maiden voyage. We know that everything isn't perfect but we want to get out there a drive these things. There are always a couple " known " loose ends. Today, I didn't actually think too much before I took it off the jack stands. I knew the brakes worked while on the stands and the trans went through all the gears...I even knew all my leaks were fixed. The wheels were tight and the steering shaft was connected....what more do ya need ? GAS....that's what !!! You need gas, lol

Because of the little mishap...no video or data log of my short cruise. There will be one coming sooner than later. Next time I'll have dinosaur juice.

I pulled my laptop out and hooked up to the megasquirt...started the car and it would not idle without playing with the throttle. I set my required fuel from 10.3 to eventually 9.5 and it idles fine. Take it out to drive through my neighborhood, which includes a steep down grade. The clutch goes in and the other big foot presses on the brake pedal. When the car stopped it promptly cut off...fired her up and she drove forward some more ( on the down grade )...I hit the brakes and she cut off again...wtf. At the second time I was looking at the fuel pressure gauge and caught it fluctuate...which made me look at the gas gauge. Guess what I saw.....you're correct...I was out of gas. Threw her in reverse and slowly reversed back to my driveway. lol.

A trip to the gas station to fill the can with 93 and Dusty was purring again. Its amazing what fuel can do to a vehicle. madmike1157 was on my mind the whole time. There's so much excitement going on when you start out on a maiden voyage. We know that everything isn't perfect but we want to get out there a drive these things. There are always a couple " known " loose ends. Today, I didn't actually think too much before I took it off the jack stands. I knew the brakes worked while on the stands and the trans went through all the gears...I even knew all my leaks were fixed. The wheels were tight and the steering shaft was connected....what more do ya need ? GAS....that's what !!! You need gas, lol

Because of the little mishap...no video or data log of my short cruise. There will be one coming sooner than later. Next time I'll have dinosaur juice.

- Dec 19, 2010

- 5,719

- 4,238

- 224

I've been pulling my hair out trying to make a restrictor for my turbo. My old nitrous jets seem to be a different angle than the -4 AN line that came from on3. My jets were in nozzles that -3 AN line screwed on. I can easily machine the brass 90° on3 sent to accept a .063 nitrous jet....but....if the line doesn't seal I'm screwed.

I could always just order one from on3...but I want to make my own....wah wah waaaah ! Lol

I'm not actually pulling my hair out....nor am I actually crying. I think I'm getting used to this. ( sigh of relief )

Someone already thought of this...all I've got to do is shell out a little cash.

Hey man, all you have to do is get a piece of sheet metal and sandwich it between your oil inlet and the turbo with a hole drilled thru for the restrictor. If you don't have the flanged fitting, get some 1/4 thick aluminum to make the flange and drill/tap it to whatever pipe thread you need to screw an npt/an fitting into, then put your orifice restrictor under the flange. Make extra gaskets from parts store gasket matl. Easy peasy.