- Mar 2, 2015

- 6,822

- 5,858

- 203

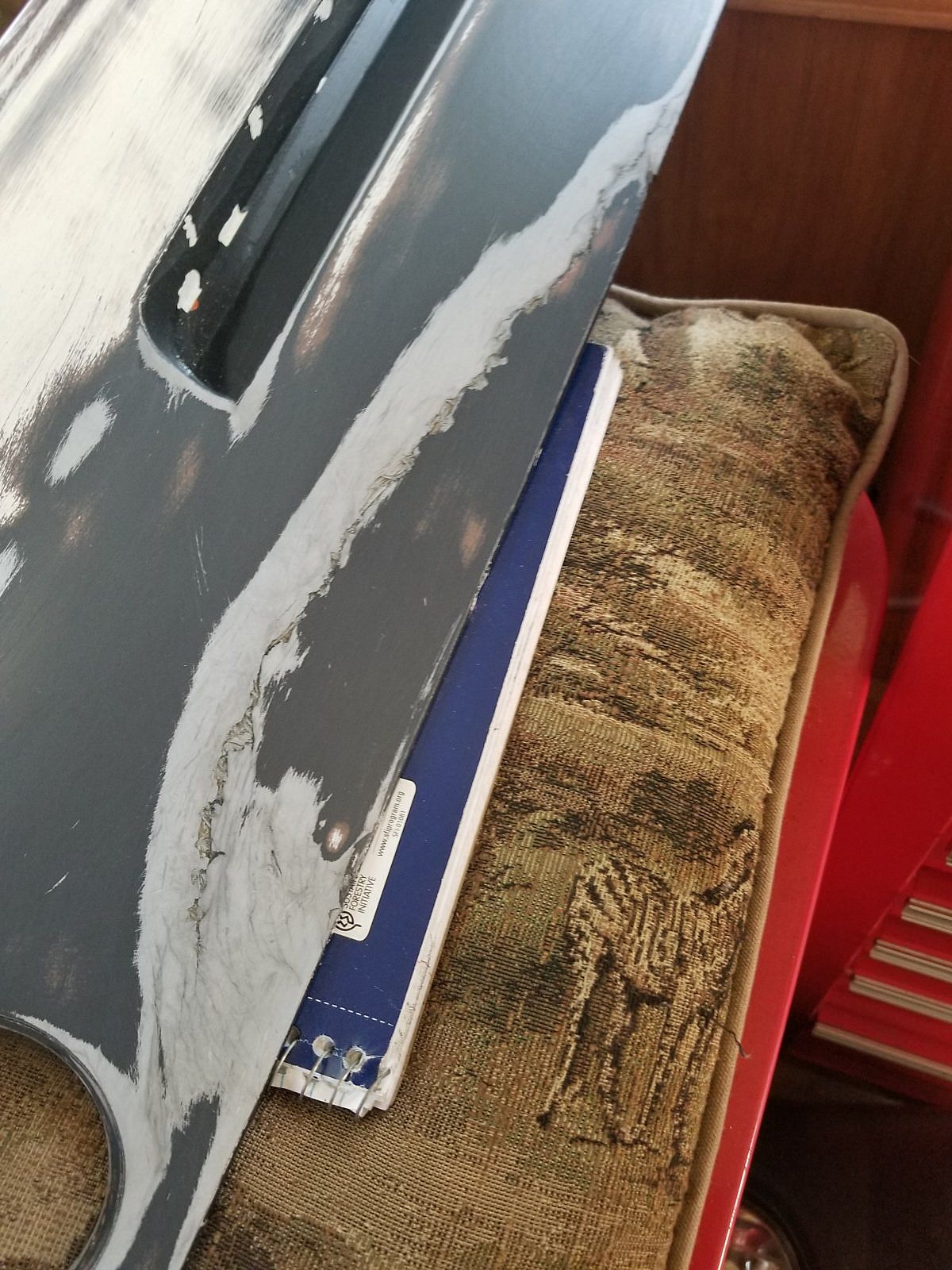

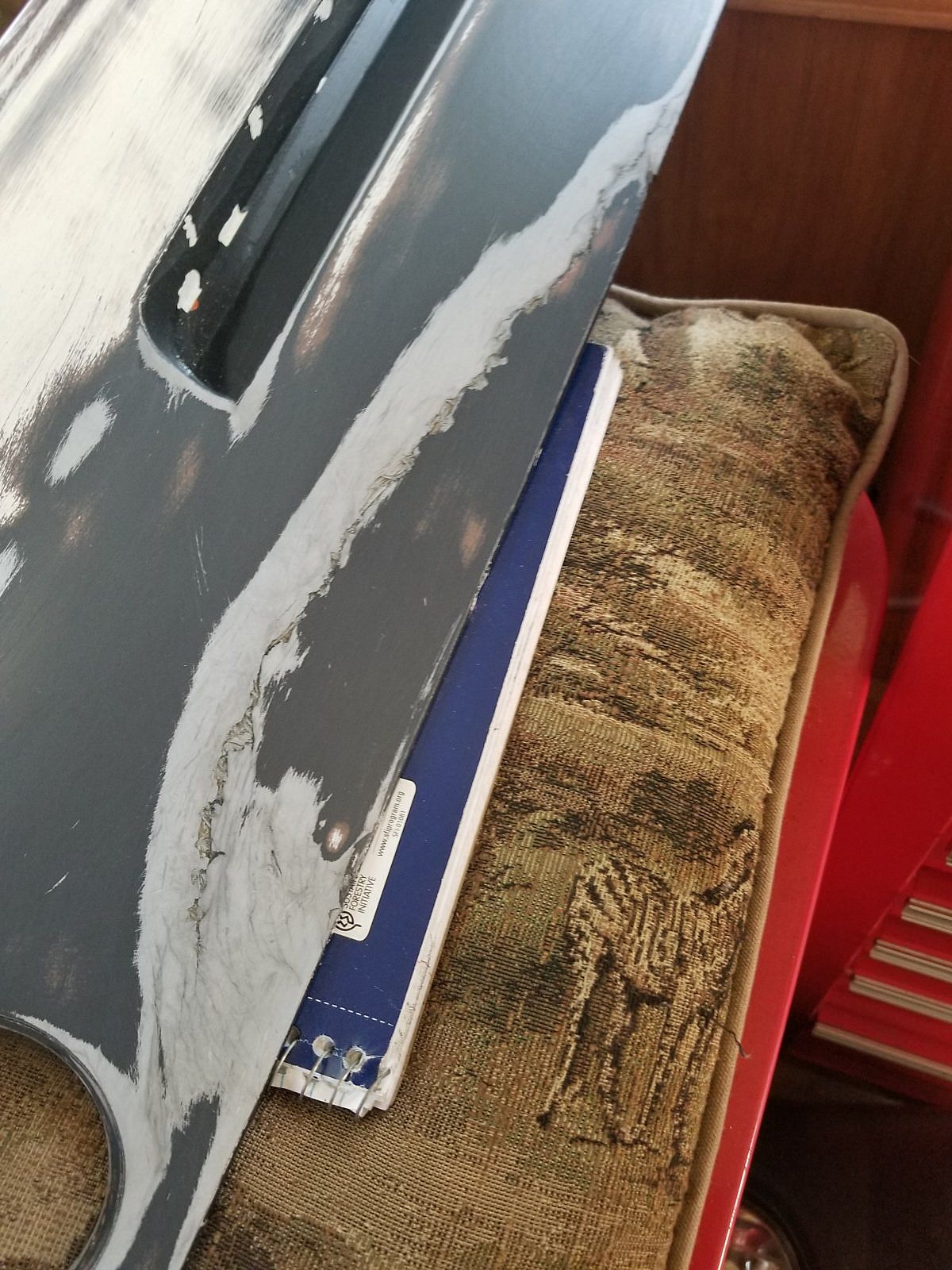

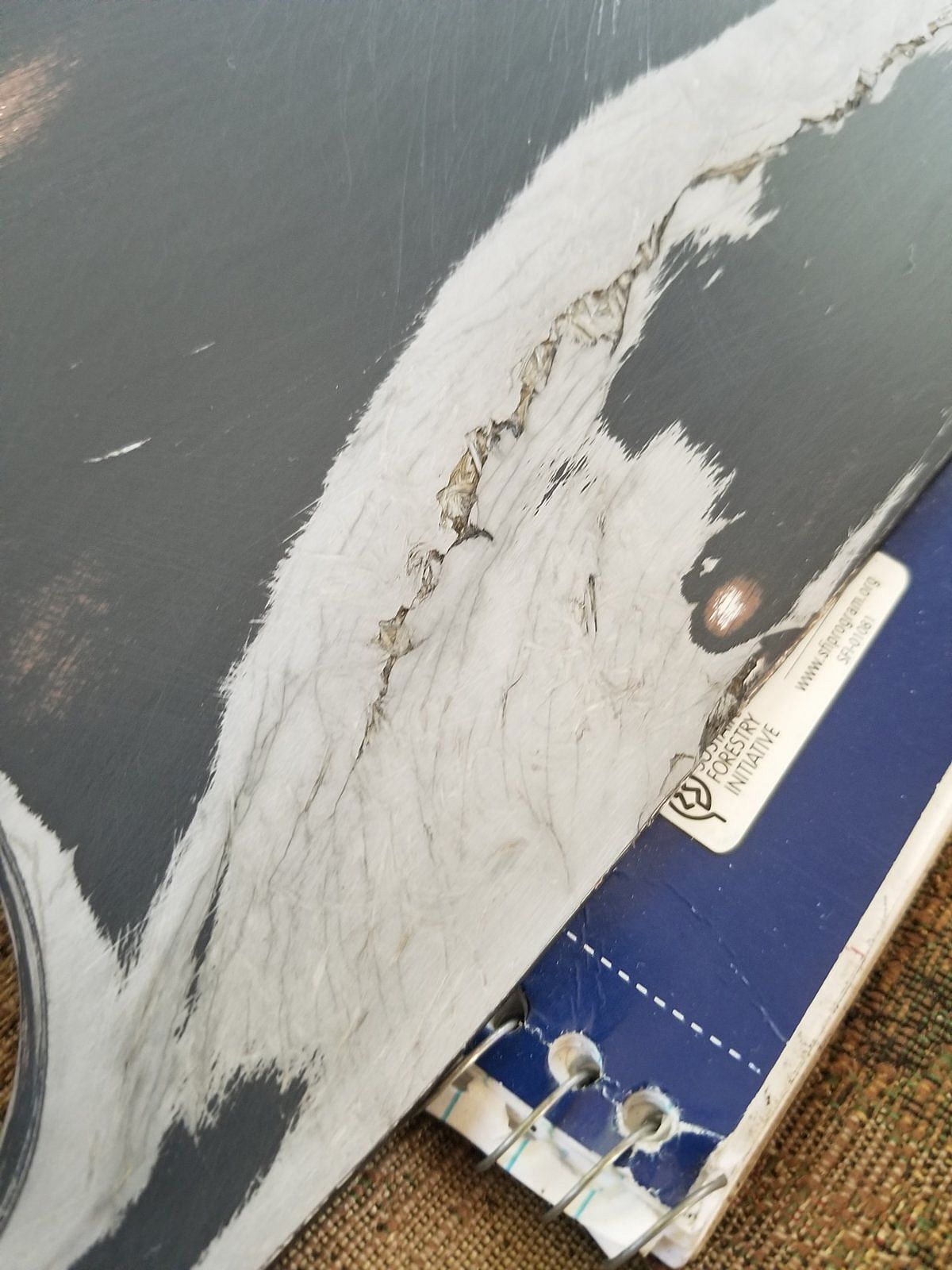

The wing is coming together. Sanded through the layers of paint and got down to the nitty gritty.

This thing has a pretty decent series of cracks. I'll need some advise from davedacarpainter for this one....

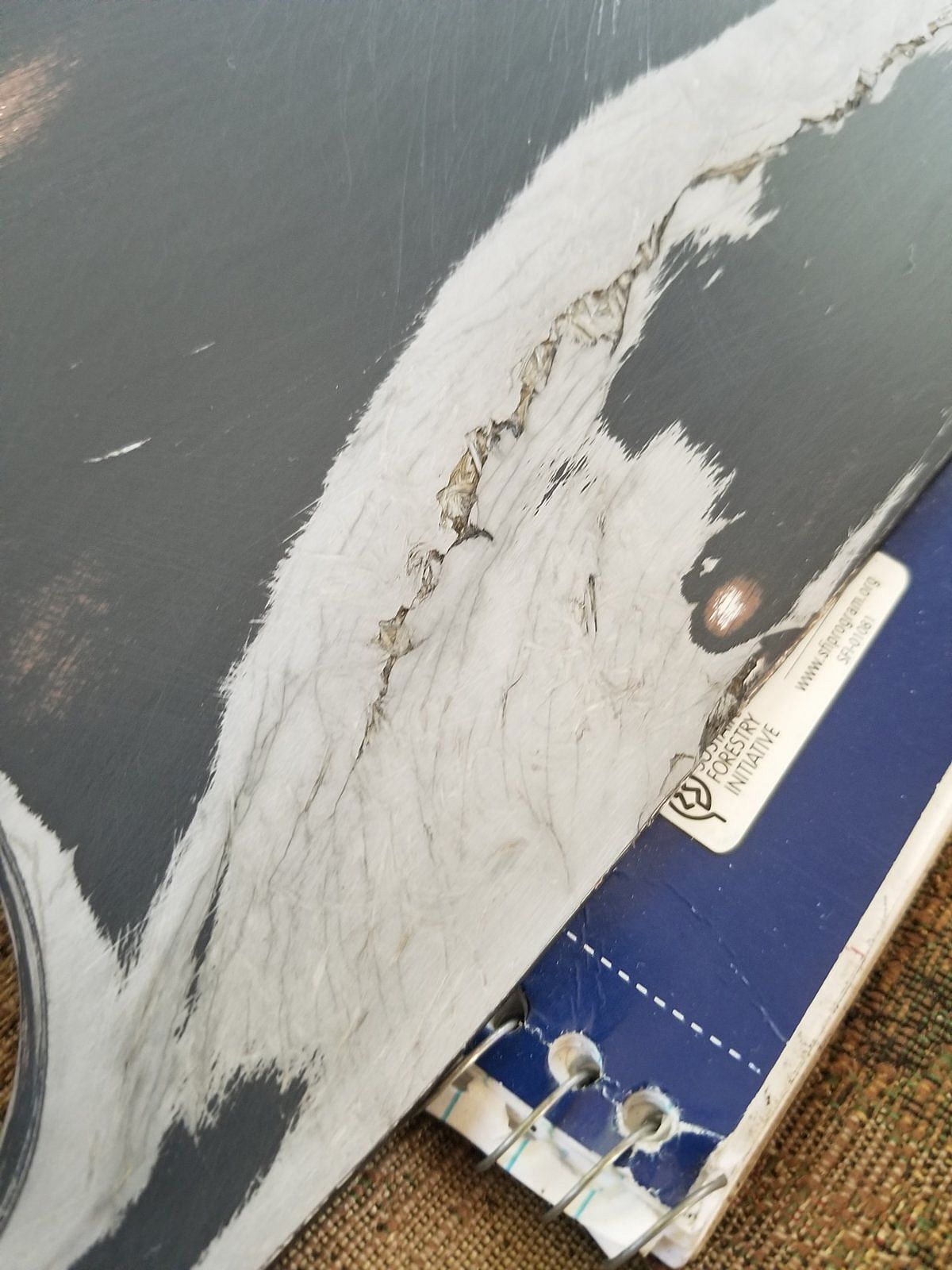

Here's a close up...

They don't seem to go all the way through.

I need some help with this one fellas. I have some fiberglass resin jelly. Figure I can grind it out with the dremel and spread some jelly with some fiberglass reinforcement strands in it. Then I would use filler over it. I don't want this thing coming back. The questions are ... do i need to grind all those little cracks out, too ? What's the best way to tackle this crapola ?

This thing has a pretty decent series of cracks. I'll need some advise from davedacarpainter for this one....

Here's a close up...

They don't seem to go all the way through.

I need some help with this one fellas. I have some fiberglass resin jelly. Figure I can grind it out with the dremel and spread some jelly with some fiberglass reinforcement strands in it. Then I would use filler over it. I don't want this thing coming back. The questions are ... do i need to grind all those little cracks out, too ? What's the best way to tackle this crapola ?

Last edited: