You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Build Thread Want To Blow 5 Years And $50k On A Foxbody? Step By Step Instructions Inside!

- Thread starter RacEoHolic330

- Start date

-

Sponsors (?)

Mine was for my t5 I just used the tko kit that came with it when I bought ityea mine was also for a TKO-600 originally and i used a adapter to set the driveline angle and use the stifflers crossmember. Interesting the the 600 goes the other way.

Sent from my iPhone using my fingers while my auto correct makes me seem illiterate

So I guess I'm the only one using a stock crossmember with a tko these days?

Other than the looks, is there any real good reason to use the stiflers over a stock one? I can't see it really being any lighter.

Other than the looks, is there any real good reason to use the stiflers over a stock one? I can't see it really being any lighter.

It's a nice solid piece and doesn't have anywhere near the flex my stock didSo I guess I'm the only one using a stock crossmember with a tko these days?

Other than the looks, is there any real good reason to use the stiflers over a stock one? I can't see it really being any lighter.

Sent from my iPhone using my fingers while my auto correct makes me seem illiterate

After looking on Stifflers site, there is a very good chance that I have the T56 crossmember. Oh well, at least I won't need to change it if (read: when) I switch to a T56.

Will do. It will probably be a winter project. I'll be shopping for parts to see what pops up in the classifieds between now and then.

So I guess I'm the only one using a stock crossmember with a tko these days?

Other than the looks, is there any real good reason to use the stiflers over a stock one? I can't see it really being any lighter.

I used the stock one for as long as i could, i switched to the stifflers cause the stock one wouldnt work with the new transmission. With the fragile TKO case in my setup i actually preferred more flex at the transmission mount, that my have been why i broke 2 transmissions pretty bad and never cracked a case.

I spoke with the fuel pump company (Fuelab) and the fuel line company (TechAFX) today. After Fuelab told me to check a few things to make sure its not a pump or regulator problem, they said that it has to be a routing issue. TechAFX basically told me the same thing. Braided lines will hold more heat, but having them anywhere near heat sources will not help. I think my close muffler proximity is to blame. I'm going to put some fire sleeve on the lines in the engine bay, but I think I definitely need to get the lines away from the mufflers.

I did take a car for a short drive. Got on it a little bit too. Saw 13.6 psi on the 13 psi gate spring setup. At least the turbo setup is working well. Now let's see if I can get the fuel to take a chill pill.

The plan will be to route the fuel lines through the frame rail with causing me the least amount of disassembly and grief possible. The IRS makes accessing anything behind the car nearly impossible, so this should be fun.

Remember when I drilled through the return line when I was mounting the fender? That gave me a great disconnect point to avoid having to remove the line directly from the tank. There are factory holes in the frame rail right at the top of the rear wheel wells. The lines can then exit out the side of the frame rail about a foot behind the firewall. I'll need to remove the feed line from the sump though.

Why I didn't do this in the first place is beyond me. What made me think fuel lines an inch from a muffler is a good idea either? I'm starting to feel like our pal Do It Twice Mike!

I blame you guys. You're all supposed to stop me from making dumb decisions like this.

The plan will be to route the fuel lines through the frame rail with causing me the least amount of disassembly and grief possible. The IRS makes accessing anything behind the car nearly impossible, so this should be fun.

Remember when I drilled through the return line when I was mounting the fender? That gave me a great disconnect point to avoid having to remove the line directly from the tank. There are factory holes in the frame rail right at the top of the rear wheel wells. The lines can then exit out the side of the frame rail about a foot behind the firewall. I'll need to remove the feed line from the sump though.

Why I didn't do this in the first place is beyond me. What made me think fuel lines an inch from a muffler is a good idea either? I'm starting to feel like our pal Do It Twice Mike!

I blame you guys. You're all supposed to stop me from making dumb decisions like this.

Last edited:

Would it help if I went back to the first page and created a post with instructions to use the frame rail?

Can't say that I told you so, but I am constantly referencing what not to do (and using your name) when it comes to drilling holes.

And now that I think of it, you do your fair share of " doing it twice" kinda stuff.

And now that I think of it, you do your fair share of " doing it twice" kinda stuff.

I'm very guilty of doing things twice. I've already admitted that I'm mostly learning as I go with this car. Some do it twice events have just cost me more money than I would have hoped.Can't say that I told you so, but I am constantly referencing what not to do (and using your name) when it comes to drilling holes.

And now that I think of it, you do your fair share of " doing it twice" kinda stuff.

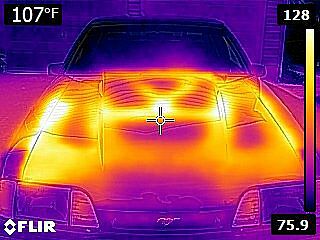

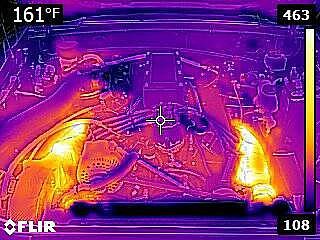

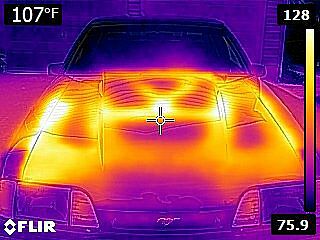

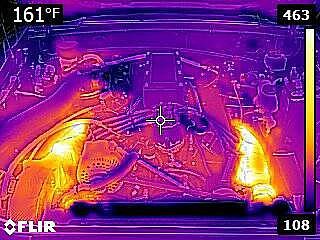

Hot stuff!

This was after a 15 minute drive without much hard acceleration, so things aren't as hot as they can be. The back side of the mufflers were into the 200 degree range. The tails were pretty hot as well. I definitely need to get the lines away from the mufflers and I may look into some stick on reflective sheets to help insulate the tank near the tail pipes. The IRS pipes aren't super close to the tank but they do surround it.

This was after a 15 minute drive without much hard acceleration, so things aren't as hot as they can be. The back side of the mufflers were into the 200 degree range. The tails were pretty hot as well. I definitely need to get the lines away from the mufflers and I may look into some stick on reflective sheets to help insulate the tank near the tail pipes. The IRS pipes aren't super close to the tank but they do surround it.

squeak93

15 Year Member

The fuel lines in the bay will be getting some heat sleeve treatment. I still need to get the lines in the frame rail though.

Number one, I'm concerned that your tailpipes pipes are getting as hot as they are me having a Gila hole that has body putty on it. And number two, where did you get the thermal imaging cameras and why do you need them?The fuel lines in the bay will be getting some heat sleeve treatment. I still need to get the lines in the frame rail though.

I don't own that camera. My coworker's wife does laser therapy on horses. She uses it to visually see the inflammation (and heat) decrease as she performs the treatments. It's a $1,500 camera. I'm going to get myself a cheap point and shoot temp gun eventually. It will be helpful to have. For now, I have a fancy camera available to me if I ever need to see something.

Similar threads

- Replies

- 32

- Views

- 40K

Progress Thread

'67 Mustang 351C > C4 trans > Clueless 21 year old

- Replies

- 5

- Views

- 2K

- Replies

- 3

- Views

- 10K

- Replies

- 1

- Views

- 7K

- Replies

- 2

- Views

- 3K