Just want to say that both VEAL and ve-analyzer both are designed to work with AE and EGO enabled. Fwiw

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1991 Turbo 306 coupe MS3/PiMPxs tuning adventure

- Thread starter wiseguyk

- Start date

-

Sponsors (?)

Cool, I knew that was a setting but never checked to see if I had it enabled. I've turned it off in the next rev of my tune.Defiantly need to disable Over-Run Fuel at this point you are in right now. That is going to throw off your numbers for sure.

Thanks for explaining, I think the biggest takeaway for me here is the steady throttle and smooth RPM sweeps. I've been driving in the neighborhood around the shop and really should find a better area where I can do this on a long straightaway or something. I can't wait to get the car back from the exhaust shop and get back to it!I do things probably a little different than others but I typically disable: Over-run fuel, EGO Control, and Accel Enrichment. I do this so there isnt anything adding/subtracting fuel while dialing in my initial VE Table. I personally do like VEAL, but just make sure you are not doing quick throttle changes. Slowly get on the throttle (25%ish), since Accel Enrichment is disabled this will make sure you dont have lean spikes. It is best to do this on an LONG open highway or street, so you can go from a stop and roll slowly up the RPM's to say 5k then shift gears and do the same thing again. Just like @a91what said you want to keep at a steady set point as long as possible. Once I get the the end of the highway or street, I pull over smooth out the VE Table, and then drive it back with VEAL on again. It typically only takes 2 trips to get an initial VE Table ironed out.

Awesome, this is my first project like this so I'm just paranoid about breaking something before I even get done tuning lol. Thanks to you awesome dudes I might actually get this thing back home again here soon!You will not hurt your engine in part/low throttle. It is WOT you have to be more careful.

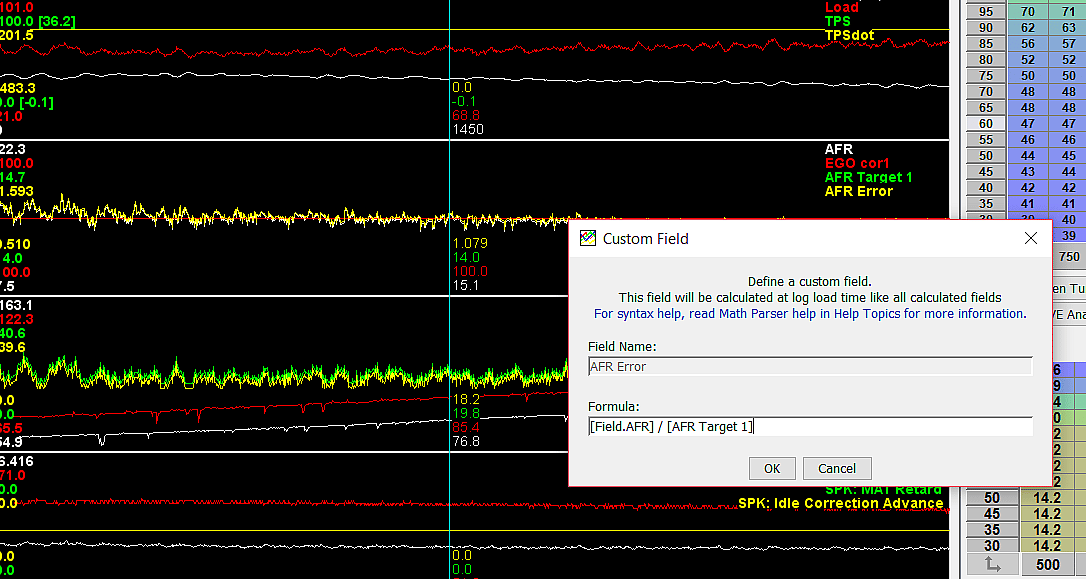

Custom error field in TS.

see the AFR error line in the log, the number in that field is what you would multiply the VE table value by.

see the AFR error line in the log, the number in that field is what you would multiply the VE table value by.

Just a quick update on the car. I'm still waiting to get it back from the exhaust shop, they have half of the Stiffler's stuff welded up and ran into an issue with the crappy On3 v-band clamps for the exhaust from the downpipe back. I had a couple extras, but they were still missing one so I ran over there yesterday and brought them one I picked up from a local speed shop so they can hopefully get the car finished up today or this weekend. Fingers crossed...

So a word of caution to anyone considering an On3 turbo kit: the v-band clamps they give you are crap and pretty much good for one use and that's it. When you remove them, the bolts twist and distort and make completely unusable I ran into this issue with the crossover pipe to header connections and turbo to downpipe connection earlier in the build and picked up new quality ones from RacePartSolutions.com. I should have gotten enough for the rest of the connections post-downpipe but I didn't. Hopefully I won't have a reason to remove the exhaust for a bit but when I do I'll definitely be ordering replacement clamps from RPS.

I ran into this issue with the crossover pipe to header connections and turbo to downpipe connection earlier in the build and picked up new quality ones from RacePartSolutions.com. I should have gotten enough for the rest of the connections post-downpipe but I didn't. Hopefully I won't have a reason to remove the exhaust for a bit but when I do I'll definitely be ordering replacement clamps from RPS.

Hopefully I'll have another update for you guys soon and I can get back to tuning this thing

So a word of caution to anyone considering an On3 turbo kit: the v-band clamps they give you are crap and pretty much good for one use and that's it. When you remove them, the bolts twist and distort and make completely unusable

I ran into this issue with the crossover pipe to header connections and turbo to downpipe connection earlier in the build and picked up new quality ones from RacePartSolutions.com. I should have gotten enough for the rest of the connections post-downpipe but I didn't. Hopefully I won't have a reason to remove the exhaust for a bit but when I do I'll definitely be ordering replacement clamps from RPS.

I ran into this issue with the crossover pipe to header connections and turbo to downpipe connection earlier in the build and picked up new quality ones from RacePartSolutions.com. I should have gotten enough for the rest of the connections post-downpipe but I didn't. Hopefully I won't have a reason to remove the exhaust for a bit but when I do I'll definitely be ordering replacement clamps from RPS.Hopefully I'll have another update for you guys soon and I can get back to tuning this thing

I picked the car up last week but it was so rainy that all I got a chance to do was to take another idle log with my newest VE table adjustments in place. It idles really well in the higher RPMs while still in the warm-up curve but once it's fully warm it surges pretty badly.

If anyone has a chance to take a look for me and give suggestions about getting the idle surge smoothed out I'd really appreciate it! Hoping to get some more shop time this week to continue onward.

If anyone has a chance to take a look for me and give suggestions about getting the idle surge smoothed out I'd really appreciate it! Hoping to get some more shop time this week to continue onward.

Attachments

- Jul 7, 2005

- 1,563

- 1,197

- 164

Couple issues I see just by a quick 5 minute look in MegaLogViewer.

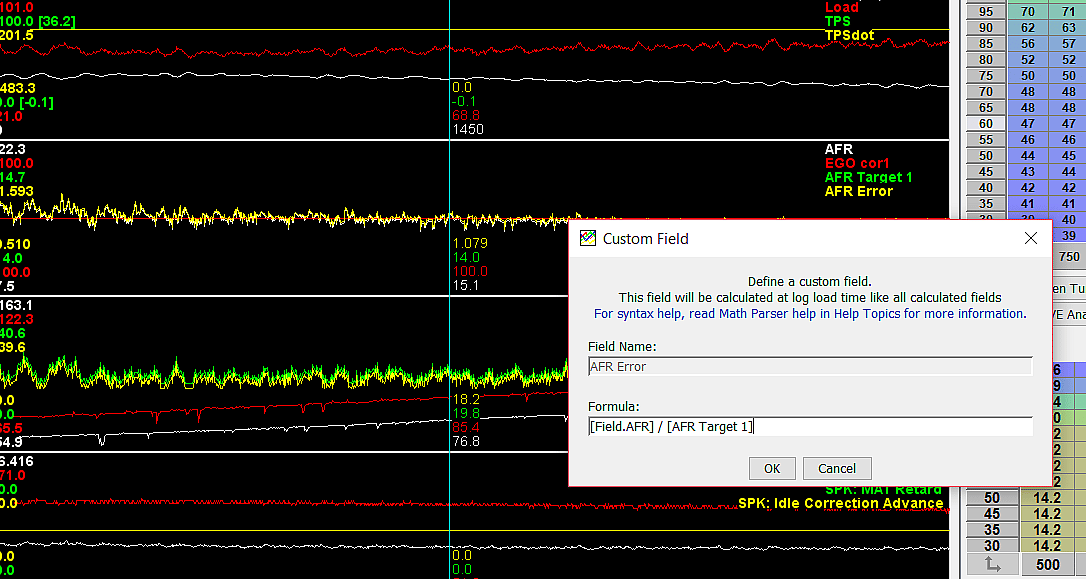

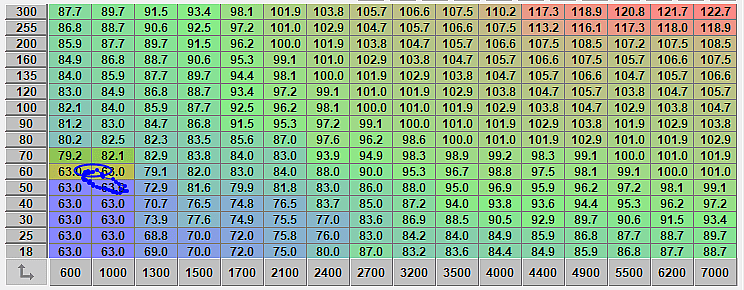

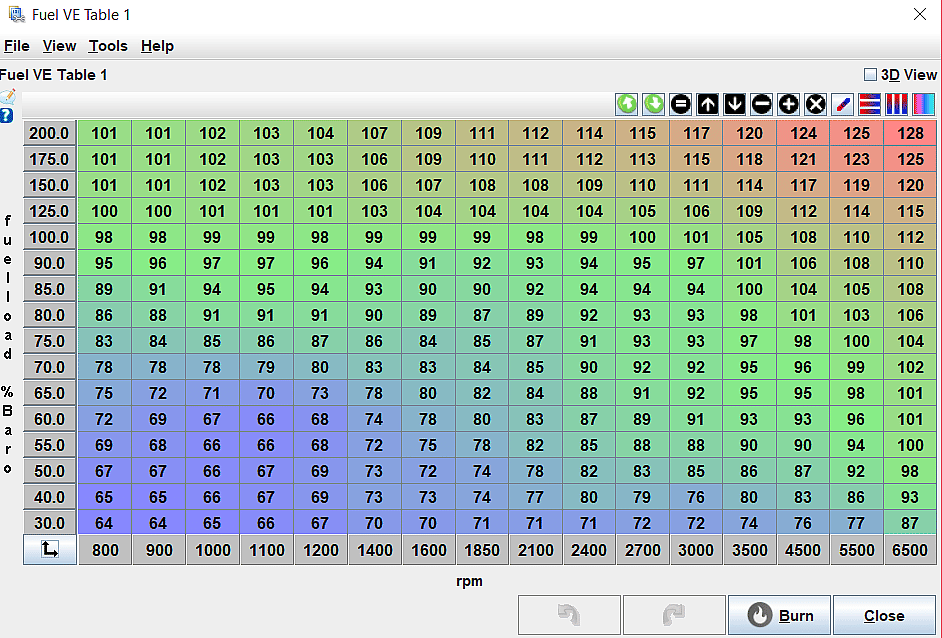

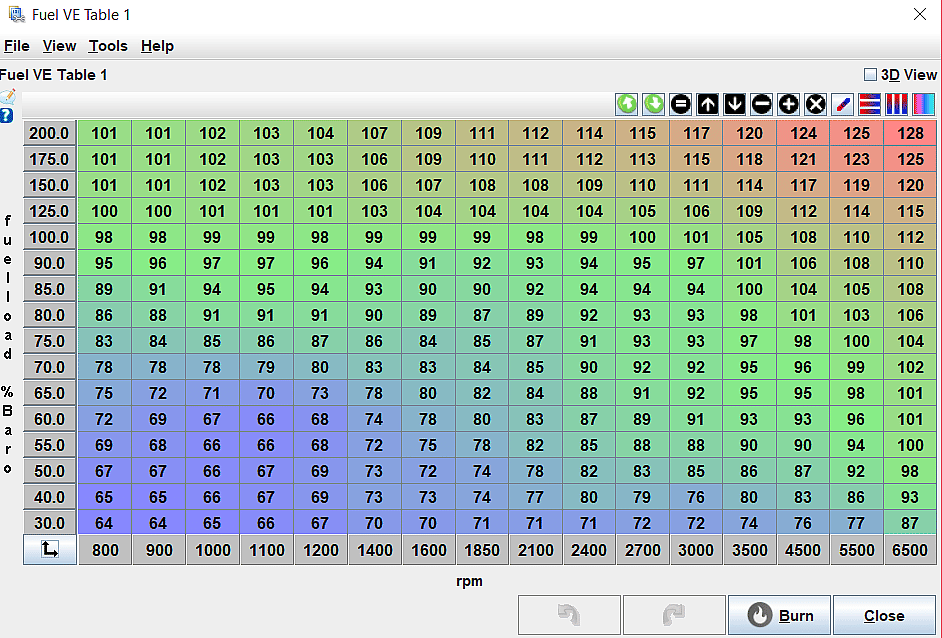

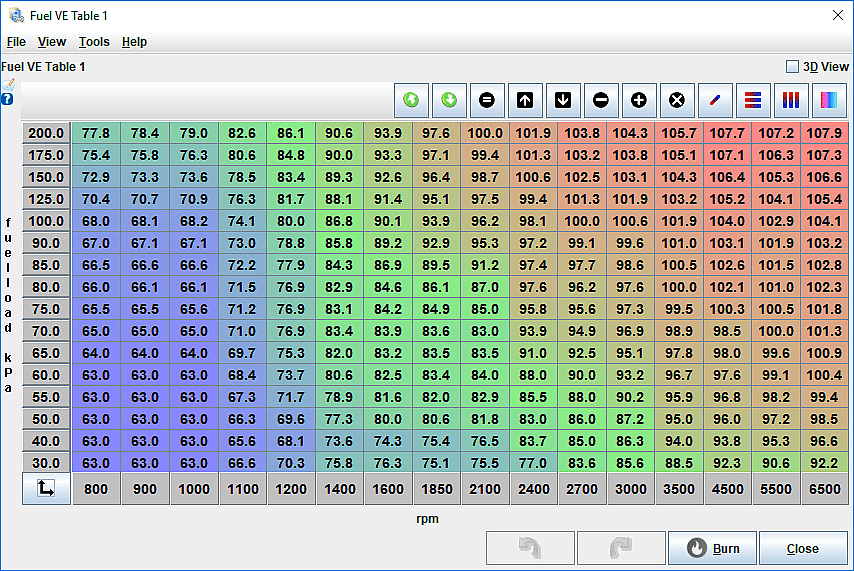

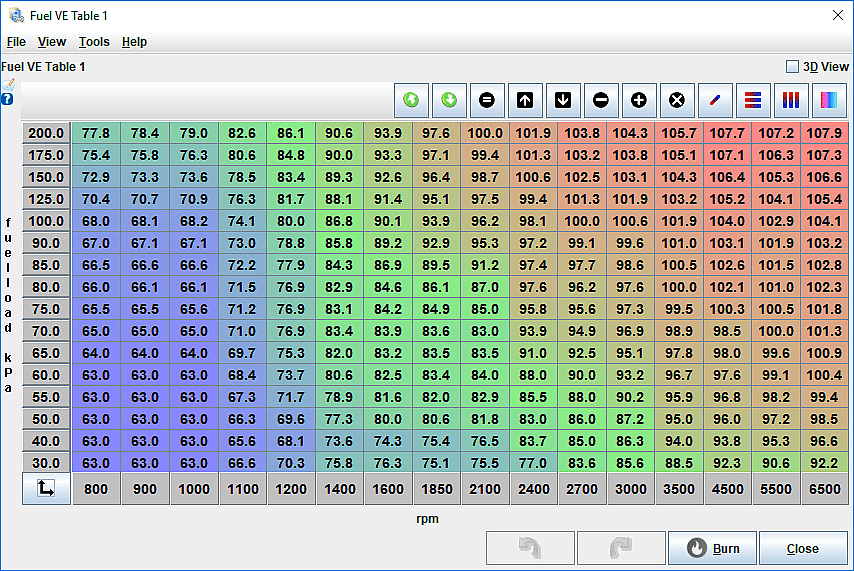

Below is your VE Table in MegaLogviewer. As you can see you are hitting the MAP reading of row 70, which is a HUGE jump in VE then it is in your row 60. This needs to be closer together at say 65 for both 600 and 1000 RPM columns and then you can blend vertically to your 300 row for those 2 columns. I would also change the 1st RPM column to 800 over the current 600 getting it closer to your Closed Loop Target RPM. This should help with the fuel surging getting the RPM's +\- 100 RPM's from your AFR Target and the VE values closer not giving large swings of fuel. This will most likely need to be tweaked as you get this dialed in more.

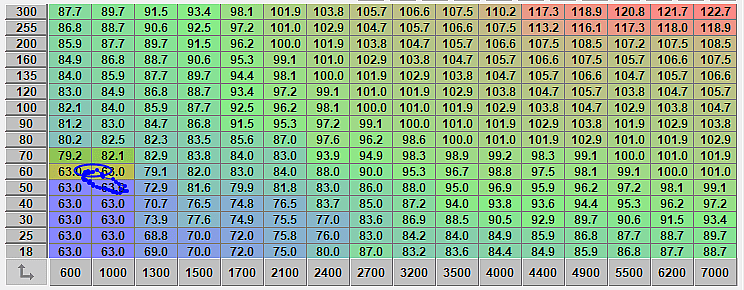

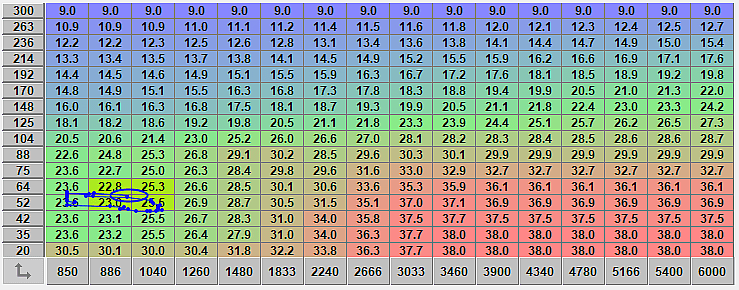

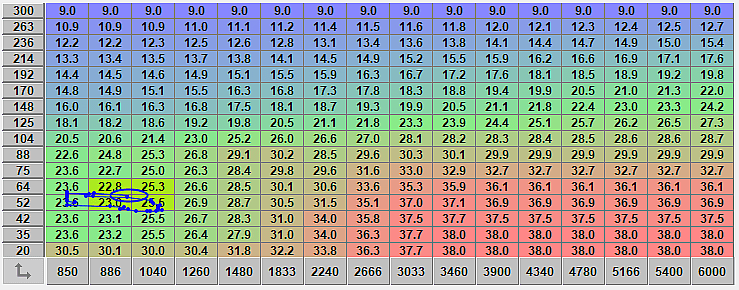

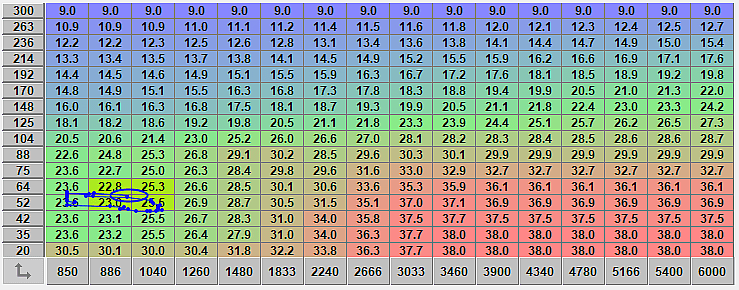

Second issue is the Spark Table that your spark changes in your idle range as well, which makes for a very unstable idle as well. I recommend changing the second column of RPM from 886 to 1000 and making the timing the same as the 850 RPM column. Then update the next 3 columns to 1200, 1400, and 1600 making it 850, 1000, 1200, 1400, 1600.

The goal you are trying to do is make everything as stable as possible for air, fuel, and spark. If any or all of these are not level then you get constant surging.

Below is your VE Table in MegaLogviewer. As you can see you are hitting the MAP reading of row 70, which is a HUGE jump in VE then it is in your row 60. This needs to be closer together at say 65 for both 600 and 1000 RPM columns and then you can blend vertically to your 300 row for those 2 columns. I would also change the 1st RPM column to 800 over the current 600 getting it closer to your Closed Loop Target RPM. This should help with the fuel surging getting the RPM's +\- 100 RPM's from your AFR Target and the VE values closer not giving large swings of fuel. This will most likely need to be tweaked as you get this dialed in more.

Second issue is the Spark Table that your spark changes in your idle range as well, which makes for a very unstable idle as well. I recommend changing the second column of RPM from 886 to 1000 and making the timing the same as the 850 RPM column. Then update the next 3 columns to 1200, 1400, and 1600 making it 850, 1000, 1200, 1400, 1600.

The goal you are trying to do is make everything as stable as possible for air, fuel, and spark. If any or all of these are not level then you get constant surging.

idle timing in ms3 is in it's own table, check under the closed loop settings. Once the car enters the "idle" engine state these idle tables take over. Ms3 has far more options than most ms2 users are used too..... everytime I work on an ms3 tune I learn something new or find a new hidden table.Couple issues I see just by a quick 5 minute look in MegaLogViewer.

Below is your VE Table in MegaLogviewer. As you can see you are hitting the MAP reading of row 70, which is a HUGE jump in VE then it is in your row 60. This needs to be closer together at say 65 for both 600 and 1000 RPM columns and then you can blend vertically to your 300 row for those 2 columns. I would also change the 1st RPM column to 800 over the current 600 getting it closer to your Closed Loop Target RPM. This should help with the fuel surging getting the RPM's +\- 100 RPM's from your AFR Target and the VE values closer not giving large swings of fuel. This will most likely need to be tweaked as you get this dialed in more.

Second issue is the Spark Table that your spark changes in your idle range as well, which makes for a very unstable idle as well. I recommend changing the second column of RPM from 886 to 1000 and making the timing the same as the 850 RPM column. Then update the next 3 columns to 1200, 1400, and 1600 making it 850, 1000, 1200, 1400, 1600.

The goal you are trying to do is make everything as stable as possible for air, fuel, and spark. If any or all of these are not level then you get constant surging.

Thanks for the input guys. Here's some tweaks I made based on your suggestions and some chatting between Steve and me and have also attached the new tune file.

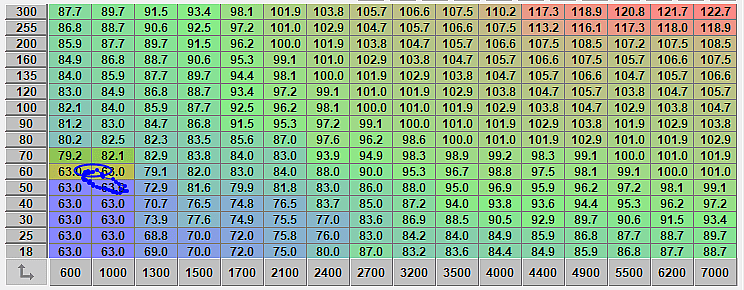

I adjusted the VE table to make the jump between 60 and 70 less drastic and then smoothed vertically for the 800 (changed from 600) and 1000 rpm column:

I'm a little concerned about the jump between the 1000 and 1300 column now though since it seems similarly drastic to the one I fixed based on @stanglx2002 suggestions. There are more big jumps as the RPMs increase too (plus some jumps in the red rectangle area) so curious what you guys think I should do about that?

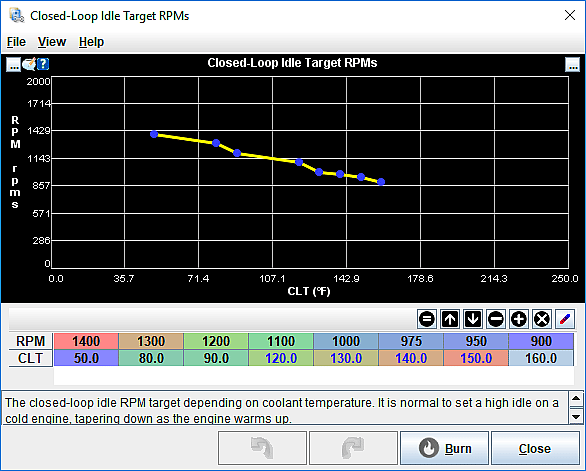

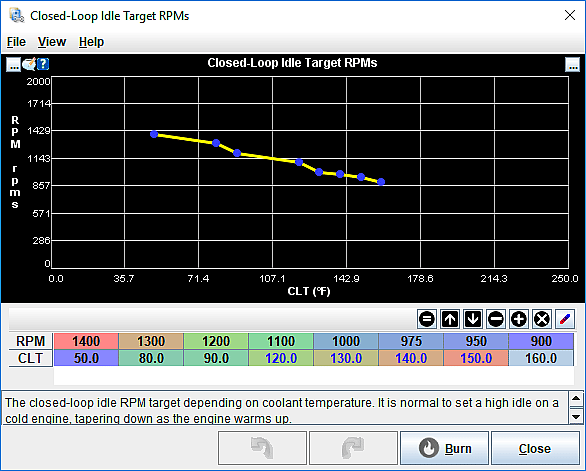

I adjusted the Closed Loop Idle Target RPM coolant values to have the final temp value at 160 instead of 140. I then adjusted the cells moving from there to the left to decrease from 160:

I made the Idle RPM Timing Correction Curve less drastic, going from 4 to -4 in 1 degree increments. I didn't change the RPM delta values at all:

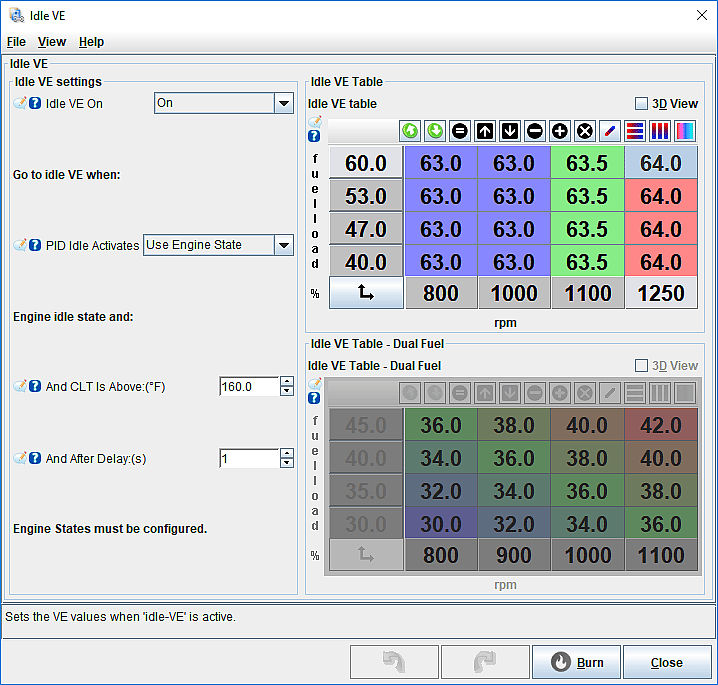

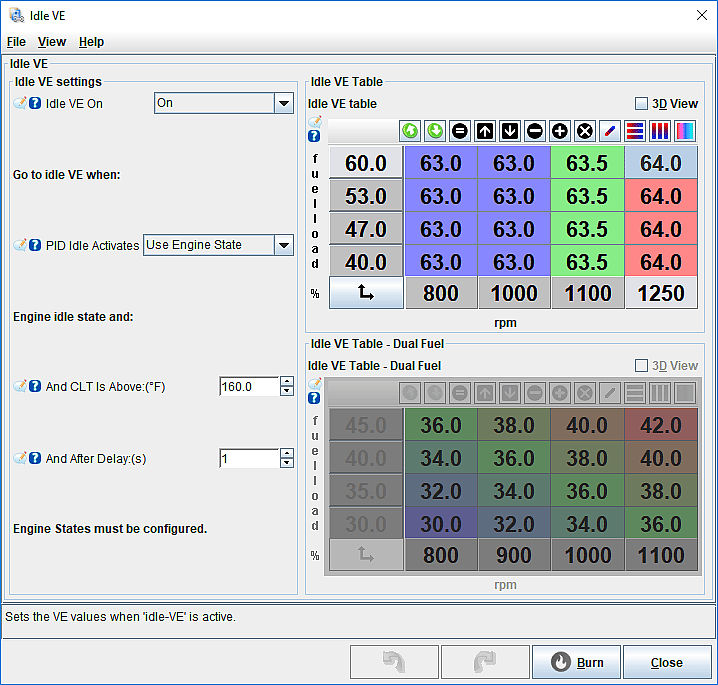

Finally, I enabled Idle VE, set the coolant temp to use it at 160, and changed the VE values to closely match my main table's idle range values:

Thanks again for all your help!

I adjusted the VE table to make the jump between 60 and 70 less drastic and then smoothed vertically for the 800 (changed from 600) and 1000 rpm column:

I'm a little concerned about the jump between the 1000 and 1300 column now though since it seems similarly drastic to the one I fixed based on @stanglx2002 suggestions. There are more big jumps as the RPMs increase too (plus some jumps in the red rectangle area) so curious what you guys think I should do about that?

I adjusted the Closed Loop Idle Target RPM coolant values to have the final temp value at 160 instead of 140. I then adjusted the cells moving from there to the left to decrease from 160:

I made the Idle RPM Timing Correction Curve less drastic, going from 4 to -4 in 1 degree increments. I didn't change the RPM delta values at all:

Finally, I enabled Idle VE, set the coolant temp to use it at 160, and changed the VE values to closely match my main table's idle range values:

Thanks again for all your help!

Attachments

IMO your load value in the fuel table is really high.... you can lower it unless you plan on running more than 15psi. 300kpa is 30psi.....

MS3 has so much more table resolution you should take advantage of it and shift some of the columns to the left, you will want more columns between the idle and cruise ranges [below 3k rpm] and above that you only need one every 500 -1000 rpm you spend very little time above 3k rpm and when you do it is mostly wot anyway.

this is how i have mine in MS2

notice how heavily i filled the bottom of the rpm map, this car was driven daily before i decided to rebuild. It worked out well for me to have a column every 100rpm in the idle range to keep fuel right where the car wanted it, with the blower intake fuel reversion was a serious problem this helped significantly.

smooth smooth smooth its more important to have smooth number transitions than it is to be spot on the AFR target. being .1 AFR off isnt even noticeable

MS3 has so much more table resolution you should take advantage of it and shift some of the columns to the left, you will want more columns between the idle and cruise ranges [below 3k rpm] and above that you only need one every 500 -1000 rpm you spend very little time above 3k rpm and when you do it is mostly wot anyway.

this is how i have mine in MS2

notice how heavily i filled the bottom of the rpm map, this car was driven daily before i decided to rebuild. It worked out well for me to have a column every 100rpm in the idle range to keep fuel right where the car wanted it, with the blower intake fuel reversion was a serious problem this helped significantly.

smooth smooth smooth its more important to have smooth number transitions than it is to be spot on the AFR target. being .1 AFR off isnt even noticeable

- Jul 7, 2005

- 1,563

- 1,197

- 164

@a91what will add/correct my advice to my comments below...

VE Table

- I recommended smaller jumps in the lower RPM's and then larger in the higher RPM's

- What is your cruising RPM range? (ie: mine is 1500-2000 RPM's) so I set a 200 RPM difference from idle through cruising, which gives good resolution in low MAP & AFR and high Timing to combat bucking. You then progressively increase the RPM's in a linear fashion.

Closed Loop Idle Target RPM

- Im OCD so I would have to blend the CLT to make that curve smoother

- Big jump from 120 to 130 CLT of 100 RPM

- Make it easy on yourself and highlight the whole row of CLT and blend

Idle RPM Timing Correction Curve

- I give a +\- 50 RPM delta before timing correction buts that's just me

- You also have more resolution with MS3 then I do

- Stock cams you could get away with 2-3 degrees timing from 50 to 100 RPM delta but need more with choppier cams say 4-6*

Idle VE

- I would set the MAP +\- 10 from your idle MAP reading, meaning if you idle at 60 then your MAP would be 70, 63, 57, 50.

- I keep the smaller resolution in the middle where you want idle to be, also giving good resolution too

- Set your 800 and 1000 RPM VE values all the same currently until you get a stable idle, which you can then adjust to make AFR target and AFR match

- I always try to make everything as linear as possible until I get a stable idle then adjust. If you don't then it makes it harder for you to figure out what is making it unstable

- I always tune in warm-up mode first then enable CL after I can get a mostly stable idle, but I do things differently than others

VE Table

- I recommended smaller jumps in the lower RPM's and then larger in the higher RPM's

- What is your cruising RPM range? (ie: mine is 1500-2000 RPM's) so I set a 200 RPM difference from idle through cruising, which gives good resolution in low MAP & AFR and high Timing to combat bucking. You then progressively increase the RPM's in a linear fashion.

Closed Loop Idle Target RPM

- Im OCD so I would have to blend the CLT to make that curve smoother

- Big jump from 120 to 130 CLT of 100 RPM

- Make it easy on yourself and highlight the whole row of CLT and blend

Idle RPM Timing Correction Curve

- I give a +\- 50 RPM delta before timing correction buts that's just me

- You also have more resolution with MS3 then I do

- Stock cams you could get away with 2-3 degrees timing from 50 to 100 RPM delta but need more with choppier cams say 4-6*

Idle VE

- I would set the MAP +\- 10 from your idle MAP reading, meaning if you idle at 60 then your MAP would be 70, 63, 57, 50.

- I keep the smaller resolution in the middle where you want idle to be, also giving good resolution too

- Set your 800 and 1000 RPM VE values all the same currently until you get a stable idle, which you can then adjust to make AFR target and AFR match

- I always try to make everything as linear as possible until I get a stable idle then adjust. If you don't then it makes it harder for you to figure out what is making it unstable

- I always tune in warm-up mode first then enable CL after I can get a mostly stable idle, but I do things differently than others

Hey guys, I've made some changes based on your suggestions and wanted to share the new tune and some of the changes I made to see what you think.

I'm planning on getting over to the shop after work today to put the fender liners back in and the interior back together. I definitely plan on doing some more idle tuning too and maybe some driving tuning but wanted to shoot you over these changes first to see if there's any more dialing in we can do before I go there tonight.

Since I don't really know exactly what my cruising range is (haven't hit 5th gear yet in my short drives) I went ahead and used your RPM and MAP settings since we have a similar motor/cam setup. I hope you don't mind me plagiarizing that My rear end gear is 3.08 and 5th gear is 0.63 if that helps at all to estimate...

My rear end gear is 3.08 and 5th gear is 0.63 if that helps at all to estimate...

Another question I thought of is do I now need to adjust my AFR and Ignition tables MAP and RPM values to match the VE changes? The Ignition table is 16x16 like the VE table, but AFR is 12x12. I haven't touched them as of right now but guessing I'll at least need to adjust for the change from 300 to 200 kPA. The upper RPM limits are also different...

Does that look good? Just to make sure I understand, I'll do my Idle VE changes here now rather than using the main VE table? Like, once it's warm I should be trying to change these cells to get it to idle at the 13.8 AFR in the AFR table?

As always, thanks a million for your help!

I'm planning on getting over to the shop after work today to put the fender liners back in and the interior back together. I definitely plan on doing some more idle tuning too and maybe some driving tuning but wanted to shoot you over these changes first to see if there's any more dialing in we can do before I go there tonight.

I don't have any plans to run 15psi, the WG spring is 7psi and I figure I'll just run that for now.IMO your load value in the fuel table is really high.... you can lower it unless you plan on running more than 15psi. 300kpa is 30psi.....

Since I don't really know exactly what my cruising range is (haven't hit 5th gear yet in my short drives) I went ahead and used your RPM and MAP settings since we have a similar motor/cam setup. I hope you don't mind me plagiarizing that

My rear end gear is 3.08 and 5th gear is 0.63 if that helps at all to estimate...

My rear end gear is 3.08 and 5th gear is 0.63 if that helps at all to estimate...

Do you think my table above looks decent enough, or are the jumps still bigger than I should have?VE Table

- I recommended smaller jumps in the lower RPM's and then larger in the higher RPM's

- What is your cruising RPM range? (ie: mine is 1500-2000 RPM's) so I set a 200 RPM difference from idle through cruising, which gives good resolution in low MAP & AFR and high Timing to combat bucking. You then progressively increase the RPM's in a linear fashion.

Another question I thought of is do I now need to adjust my AFR and Ignition tables MAP and RPM values to match the VE changes? The Ignition table is 16x16 like the VE table, but AFR is 12x12. I haven't touched them as of right now but guessing I'll at least need to adjust for the change from 300 to 200 kPA. The upper RPM limits are also different...

I went ahead and blended the CLT row like you suggested:Closed Loop Idle Target RPM

I left this alone for now, since I'm not really sure what they should be set to. Are you saying to have the two "middle" columns set to 0 timing and +/- 50 RPM and then go up from there?Idle RPM Timing Correction Curve

Looking at my most recent log, the car seems to idle with a MAP around 50 so I set the idle VE range like you suggested and made the cells the same for 800 and 1000 rpm:Idle VE

- I would set the MAP +\- 10 from your idle MAP reading, meaning if you idle at 60 then your MAP would be 70, 63, 57, 50.

Does that look good? Just to make sure I understand, I'll do my Idle VE changes here now rather than using the main VE table? Like, once it's warm I should be trying to change these cells to get it to idle at the 13.8 AFR in the AFR table?

As always, thanks a million for your help!

Attachments

yes you are correct and things look good to start with for now.

no issue using my values, i have a t5 with 3.08 rear gear as well. With a long runner intake you should be able to cruise as low as 1400rpm... however the car will feel as though you are lugging the engine.

no issue using my values, i have a t5 with 3.08 rear gear as well. With a long runner intake you should be able to cruise as low as 1400rpm... however the car will feel as though you are lugging the engine.

- Jul 7, 2005

- 1,563

- 1,197

- 164

You look good to go for right now. Time to dialing in the VE table more, and start using some longer datalogs (20-30 minute) in MegaLog Viewer. Then you can start making tweaks to the AFR and Spark tables based on how the car feels.

Quick upload of datalogs after master Steve's visit to the shop today  Heading home now but I wanted to upload the logs before I have to go home and actually be a productive adult lol. Full update to follow... Thanks Steve, you're the man!!!!

Heading home now but I wanted to upload the logs before I have to go home and actually be a productive adult lol. Full update to follow... Thanks Steve, you're the man!!!!

Attachments

- Jul 7, 2005

- 1,563

- 1,197

- 164

Phew! Sorry for the delay in my update, I wish I had a week of vacation to just work on the car everyday lol

So I would call yesterday a huge success Having Steve there in person to work his magic was invaluable and it was great just hanging with him too. I'll try my best to recap what we did but I'm sure I'll be forgetting some stuff and hopefully Steve can chime in with those bits

Having Steve there in person to work his magic was invaluable and it was great just hanging with him too. I'll try my best to recap what we did but I'm sure I'll be forgetting some stuff and hopefully Steve can chime in with those bits

While tackling the idle, we reset the timing, moving the rotor more to the middle of the pin because it was previously only hitting the edge of the rotor. This involved breaking out the timing light and getting the offset dialed in again in TS. Steve thinks it might need to be adjusted again as we were seeing some hesitation while doing pulls in 2nd and 3rd gear. We found that the car likes to idle pretty lean at around 14.6-15 AFR and likes more timing too, set to 25 degrees across the board for idle advance.

Steve also tweaked the IAC, ASE, and cranking settings to make it fire up more quickly than before while cold and when fully warmed up. Previously you'd have to crank for several seconds before it would fire up and now it starts right up quickly. Once we were happy enough with the idle (Steve still isn't 100% happy haha) we moved on to actually driving the damn thing

I drove while Steve ran VEAL and did manual tuning himself. The main focus was keeping an eye on the AFR and temps and since everything was looking good Steve had me do some actual 2nd and 3rd gear pulls. WOWOWOWOWOW was it awesome to feel the boost! I'm completely addicted now and I think I was even dreaming of the PSSSSH blowoff sound lol.

Aside from the (currently unknown but email has been sent to Tony at Astro transmissions) terrible sound the transmission is making, the car ran really well and I can't wait to get back over to the shop to drive it again.

I know I'm forgetting a lot, but just trying to recap real quick. I still haven't had a chance to really check out the datalogs and go over everything but am planning to do that as soon as I have time.

Thanks again to Steve for being the man and making the trek down to me. We're getting there and all these months of work are finally paying off!

Pics and vids! Please try to ignore the hideous transmission noise

Pulls:

View: https://youtu.be/7vhGaptn6F8

View: https://youtu.be/u8jv4L0HYjo

Nice smooth idle and shot of new upper radiator pipe (still need to get a couple clamps to finish) and belt squeal fix:

View: https://youtu.be/YRnuZwb70XQ

Car actually out of the shop! lol

So I would call yesterday a huge success

Having Steve there in person to work his magic was invaluable and it was great just hanging with him too. I'll try my best to recap what we did but I'm sure I'll be forgetting some stuff and hopefully Steve can chime in with those bits

Having Steve there in person to work his magic was invaluable and it was great just hanging with him too. I'll try my best to recap what we did but I'm sure I'll be forgetting some stuff and hopefully Steve can chime in with those bits While tackling the idle, we reset the timing, moving the rotor more to the middle of the pin because it was previously only hitting the edge of the rotor. This involved breaking out the timing light and getting the offset dialed in again in TS. Steve thinks it might need to be adjusted again as we were seeing some hesitation while doing pulls in 2nd and 3rd gear. We found that the car likes to idle pretty lean at around 14.6-15 AFR and likes more timing too, set to 25 degrees across the board for idle advance.

Steve also tweaked the IAC, ASE, and cranking settings to make it fire up more quickly than before while cold and when fully warmed up. Previously you'd have to crank for several seconds before it would fire up and now it starts right up quickly. Once we were happy enough with the idle (Steve still isn't 100% happy haha) we moved on to actually driving the damn thing

I drove while Steve ran VEAL and did manual tuning himself. The main focus was keeping an eye on the AFR and temps and since everything was looking good Steve had me do some actual 2nd and 3rd gear pulls. WOWOWOWOWOW was it awesome to feel the boost! I'm completely addicted now and I think I was even dreaming of the PSSSSH blowoff sound lol.

Aside from the (currently unknown but email has been sent to Tony at Astro transmissions) terrible sound the transmission is making, the car ran really well and I can't wait to get back over to the shop to drive it again.

I know I'm forgetting a lot, but just trying to recap real quick. I still haven't had a chance to really check out the datalogs and go over everything but am planning to do that as soon as I have time.

Thanks again to Steve for being the man and making the trek down to me. We're getting there and all these months of work are finally paying off!

Pics and vids! Please try to ignore the hideous transmission noise

Pulls:

View: https://youtu.be/7vhGaptn6F8

View: https://youtu.be/u8jv4L0HYjo

Nice smooth idle and shot of new upper radiator pipe (still need to get a couple clamps to finish) and belt squeal fix:

View: https://youtu.be/YRnuZwb70XQ

Car actually out of the shop! lol

- Jul 7, 2005

- 1,563

- 1,197

- 164

While tackling the idle, we reset the timing, moving the rotor more to the middle of the pin because it was previously only hitting the edge of the rotor. This involved breaking out the timing light and getting the offset dialed in again in TS. Steve thinks it might need to be adjusted again as we were seeing some hesitation while doing pulls in 2nd and 3rd gear. We found that the car likes to idle pretty lean at around 14.6-15 AFR and likes more timing too, set to 25 degrees across the board for idle advance.

@a91what - What is he talking about here dialing in the offset to the center of the rotor? Can you explain further...

basically you try and find a sweet spot where the rotor is in the center of the pin when it fires the spark... only issue is the distributor is being used for sequential injection so the pip window affects where TS will allow you to set the offset, as the offset changes the number we are shooting for in the wizard. another reason i dont like TFI setups. I think we may have to opt for the original position with a lower offset and less than optimal rotor phasing, this may be due to the MSD distributor having the pickup differ from the stock distributor.

Similar threads

- Replies

- 2

- Views

- 277

- Replies

- 8

- Views

- 2K

- Replies

- 51

- Views

- 7K

- Replies

- 31

- Views

- 15K