Thermactor Air System

Some review of how it works...

Revised 26-Jun-2105 to clarify operation of TAB & TAD solenoids

The Thermactor air pump (smog pump) supplies air to the heads or catalytic converters. This air helps break down the excess HC (hydrocarbons) and CO (carbon monoxide). The air supplied to the catalytic converters helps create the catalytic reaction that changes the HC & CO into CO2 and water vapor. Catalytic converters on 5.0 Mustangs are designed to use the extra air provided by the smog pump. Without the extra air, the catalytic converters will clog and fail.

The Thermactor air pump draws air from an inlet filter in the front of the pump. The smog pump puts air into the heads when the engine is cold and then into the catalytic converters when it is warm. The air provided by the air pump serves to help consume any unburned hydrocarbons by supplying extra oxygen to the catalytic process. With a warm engine, the computer operates on closed loop mode, taking input from all the sensors.

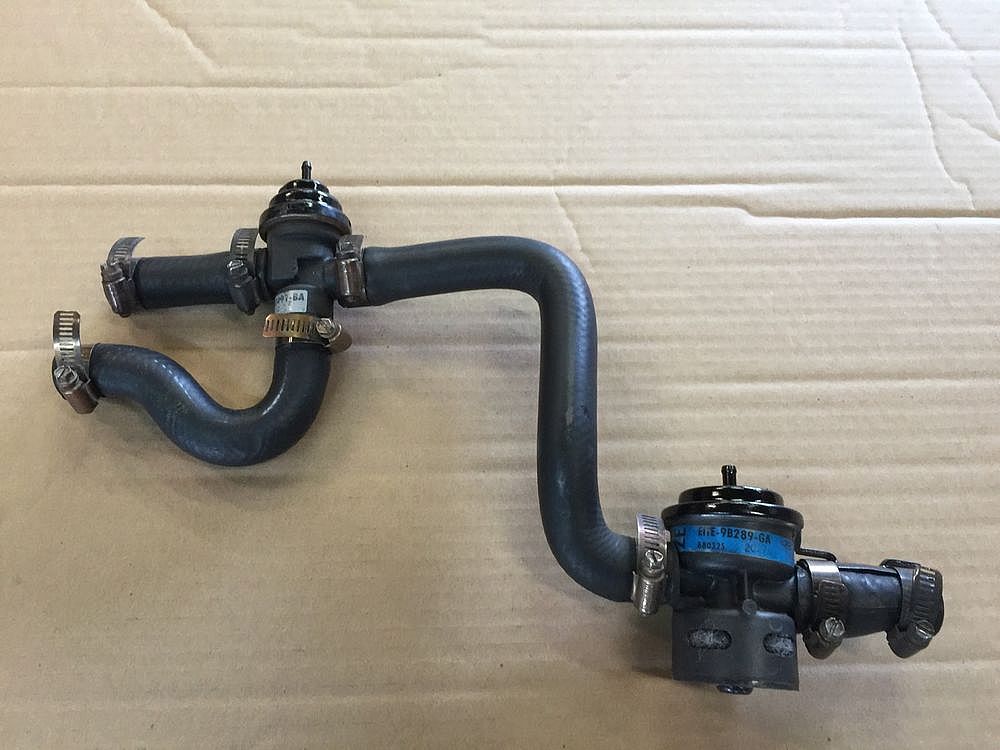

The Thermactor control valves serve to direct the flow. The first valve, TAB (Thermactor Air Bypass) or AM1 valve) either dumps air to the atmosphere or passes it on to the second valve. The computer tells the Thermactor Air System to open the Bypass valve at WOT (wide open throttle) minimizing engine drag. This dumps the pump's output to the atmosphere, and reduces the parasitic drag caused by the smog pump to about 2-4 HP at WOT. The Bypass valve also opens during deceleration to reduce or prevent backfires.

The second valve, TAD (Thermactor Air Diverter valve or AM2 valve) directs it to the heads or the catalytic converters. Check valves located after the TAD solenoid prevent hot exhaust gases from damaging the Diverter control valve or air pump in case of a backfire.

Code 44 RH side air not functioning.

Code 94 LH side air not functioning.

How the O2 sensors affect the operation of the Thermactor Air System.

The computer uses the change in the O2 sensor readings to detect operation of the Thermactor control valves. When the dump valve opens, it reduces the O2 readings in the exhaust system. Then it closes the dump valve and the O2 readings increase. By toggling the dump valve (TAB), the computer tests for the 44/94 codes.

Failure mode is usually due to a clogged air crossover tube, where one or both sides of the tube clog with carbon. The air crossover tube mounts on the back of the cylinder heads and supplies air to each of the Thermactor air passages cast into the cylinder heads. When the heads do not get the proper air delivery, they set codes 44 & 94, depending on which passage is clogged. It is possible to get both 44 & 94, which would suggest that the air pump or control valves are not working correctly, or the crossover tube is full of carbon or missing.

Computer operation & control for the Thermactor Air System.

Automobile computers use current sink technology. They do not source power to any relay, solenoid or actuator like the IAC, fuel pump relay, or fuel injectors. Instead the computer provides a ground path for the positive battery voltage to get back to the battery negative terminal. That flow of power from positive to negative is what provides the energy to make the IAC, fuel pump relay, or fuel injectors work. No ground provided by the computer, then the actuators and relays don't operate.

One side of the any relay/actuator/solenoid in the engine compartment will be connected to a red wire that has 12-14 volts anytime the ignition switch is in the run position. The other side will have 12-14 volts when the relay/actuator/solenoid isn't turned on. Once the computer turns on the clamp side, the voltage on the computer side of the wire will drop down to 1 volt or less.

In order to test the TAD/TAB solenoids, you need to ground the white/red wire on the TAB solenoid or the light green/black wire on the TAD solenoid. The TAB and TAD solenoid are located on the passenger side shock strut tower. Uneducated owners sometimes remove them to get more HP. This does not work, it just causes 81 & 82 codes.

For 94-95 cars: the colors are different. The White/Red wire (TAB control) is White/Orange (Pin 31 on the PCM). The Green/Black wire (TAD control) should be Brown (pin 34 at the PCM). Thanks to HISSIN50 for this tip.

Testing the system:

To test the computer, you can use a test light across the TAB or TAD wiring connectors and dump the codes. When you dump the codes, the computer does a self test that toggles every relay/actuator/solenoid on and off. When this happens, the test light will flicker.

Disconnect the big hose from smog pump: with the engine running you should feel air output. Reconnect the smog pump hose & apply vacuum to the first vacuum controlled valve: Its purpose is to either dump the pump's output to the atmosphere or pass it to the next valve.

The next vacuum controlled valve directs the air to either the cylinder heads when the engine is cold or to the catalytic converter when the engine is warm. Disconnect the big hoses from the back side of the vacuum controlled valve and start the engine. Apply vacuum to the valve and see if the airflow changes from one hose to the next.

The two electrical controlled vacuum valves mounted on the rear of the passenger side wheel well turn the vacuum on & off under computer control. Check to see that both valves have +12 volts on the red wire. Then ground the white/red wire and the first solenoid should open and pass vacuum. Do the same thing to the light green/black wire on the second solenoid and it should open and pass vacuum.

Remember that the computer does not source power for any actuator or relay, but provides the ground necessary to complete the circuit. That means one side of the circuit will always be hot, and the other side will go to ground or below 1 volt as the computer switches on that circuit.

The computer provides the ground to complete the circuit to power the solenoid valve that turns the

vacuum on or off. The computer is located under the passenger side kick panel. Remove the kick panel & the cover over the computer wiring connector pins. Check Pin 38 Solenoid valve #1 that provides vacuum to the first Thermactor control valve for a switch from 12-14 volts to 1 volt or less. Do the same with pin 32 solenoid valve #2 that provides vacuum to the second Thermactor control valve. Starting the engine with the computer jumpered to self test mode will cause all the actuators to toggle on and off. If after doing this and you see no switching of the voltage on and off, you can start testing the wiring for shorts to ground and broken wiring. An Ohm check to ground with the computer connector disconnected & the solenoid valves disconnected should show open circuit between the pin 32 and ground and again on pin 38 and ground. In like manner, there should be less than 1 ohm between pin 32 and solenoid valve #2 and pin 38 & Solenoid valve #1.

If after checking the resistance of the wiring & you are sure that there are no wiring faults, start looking at the solenoid valves. If you disconnect them, you can jumper power & ground to them to verify operation. Power & ground supplied should turn on the vacuum flow, remove either one and the vacuum should stop flowing.

Typical resistance of the solenoid valves is in the range of 20-70 Ohms.

Theory of operation:

Catalytic converters consist of two different types of catalysts: Reduction and Oxidation.

The Reduction catalyst is the first converter in a 5.0 Mustang, and the Oxidation converter is the second converter. The Oxidation converter uses the extra air from the smog pump to burn the excess HC. Aftermarket converters that use the smog pump often combine both types of catalysts in one housing. Since all catalytic reactions depend on heat to happen, catalytic converters do not work as efficiently with long tube headers. The extra length of the long tubes reduces the heat available to operate the O2 sensors and the catalytic converters. That will cause emissions problems, and reduce the chances of passing an actual smog test.

Now for the Chemistry...

"The reduction catalyst is the first stage of the catalytic converter. It uses platinum and rhodium to help reduce the NOx emissions. When an NO or NO2 molecule contacts the catalyst, the catalyst rips the nitrogen atom out of the molecule and holds on to it, freeing the oxygen in the form of O2. The nitrogen atoms bond with other nitrogen atoms that are also stuck to the catalyst, forming N2. For example:

2NO => N2 + O2 or 2NO2 => N2 + 2O2

The oxidation catalyst is the second stage of the catalytic converter. It reduces the unburned hydrocarbons and carbon monoxide by burning (oxidizing) them over a platinum and palladium catalyst. This catalyst aids the reaction of the CO and hydrocarbons with the remaining oxygen in the exhaust gas. For example:

2CO + O2 => 2CO2

There are two main types of structures used in catalytic converters -- honeycomb and ceramic beads. Most cars today use a honeycomb structure." Quote courtesy of How Stuff Works (

HowStuffWorks "Catalysts")

What happens when there is no extra air from the smog pump...

As engines age, the quality of tune decreases and wear causes them to burn oil. We have all seem cars that go down the road puffing blue or black smoke from the tailpipe. Oil consumption and poor tune increase the amount of HC the oxidation catalyst has to deal with. The excess HC that the converters cannot oxidize due to lack of extra air becomes a crusty coating inside the honeycomb structure. This effectively reduces the size of the honeycomb passageways and builds up thicker over time and mileage. Continuous usage under such conditions will cause the converter to fail and clog. The extra air provided by the Thermactor Air System (smog pump) is essential for the oxidation process. It oxidizes the added HC from oil consumption and poor tune and keeps the HC levels within acceptable limits.

Newer catalytic converters do not use the Thermactor Air System (smog pump) because they are designed to work with an improved computer system that runs leaner and cleaner

Newer catalytic converters do not use the Thermactor Air System (smog pump) because they are designed to work with an improved computer system that runs leaner and cleaner

They add an extra set of O2 sensors after the catalytic converters to monitor the oxygen and HC levels. Using this additional information, the improved computer system monitors the health and efficiency of the catalytic converters. If the computer cannot compensate for the added load of emissions due to wear and poor tune, the catalytic converters will eventually fail and clog. The periodic checks (smog inspections) are supposed to help owners keep track of problems and get them repaired. Use them on an 86-95 Mustang and you will slowly kill them with the pollutants that they are not designed to deal with.