Howdy all! Long time, no see. Been a bit crazy with life. I had my busiest year ever at work, had carpel tunnel surgery on one hand, my daughter is on 3 cheer teams at a very competitive level, my wife and I have been traveling a ton, blah, blah, blah.

Anyway, to the Mustang.

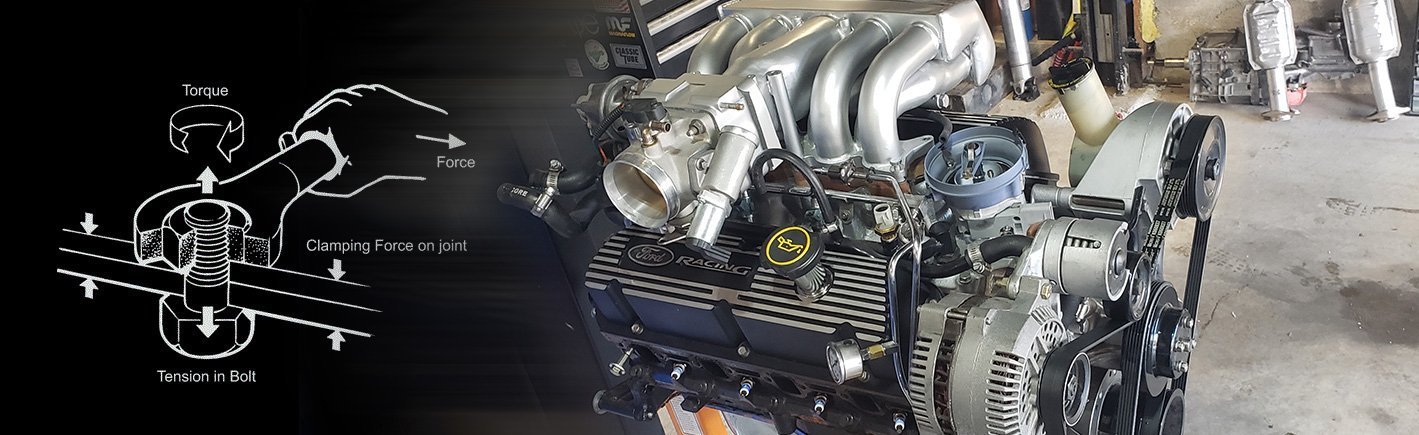

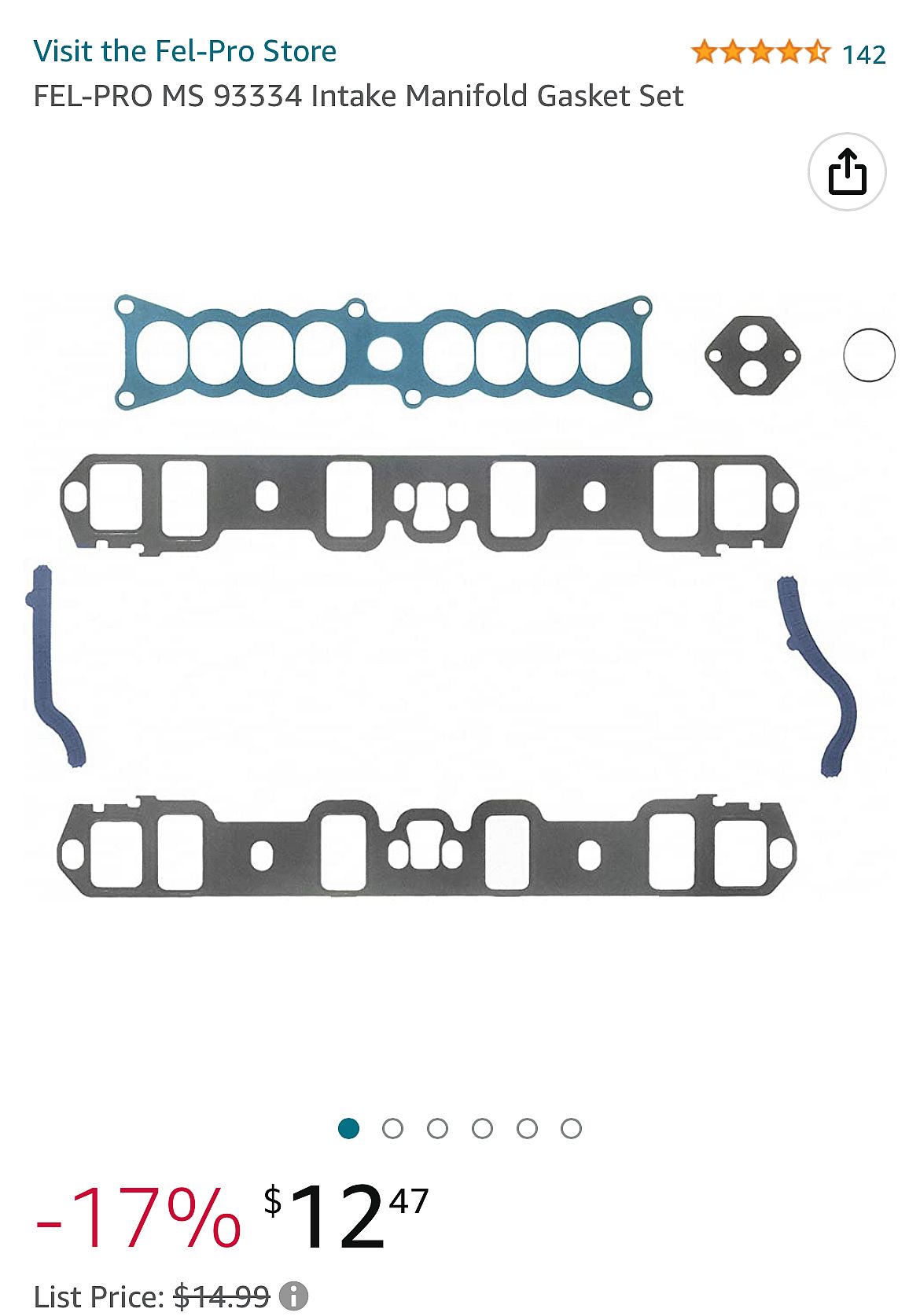

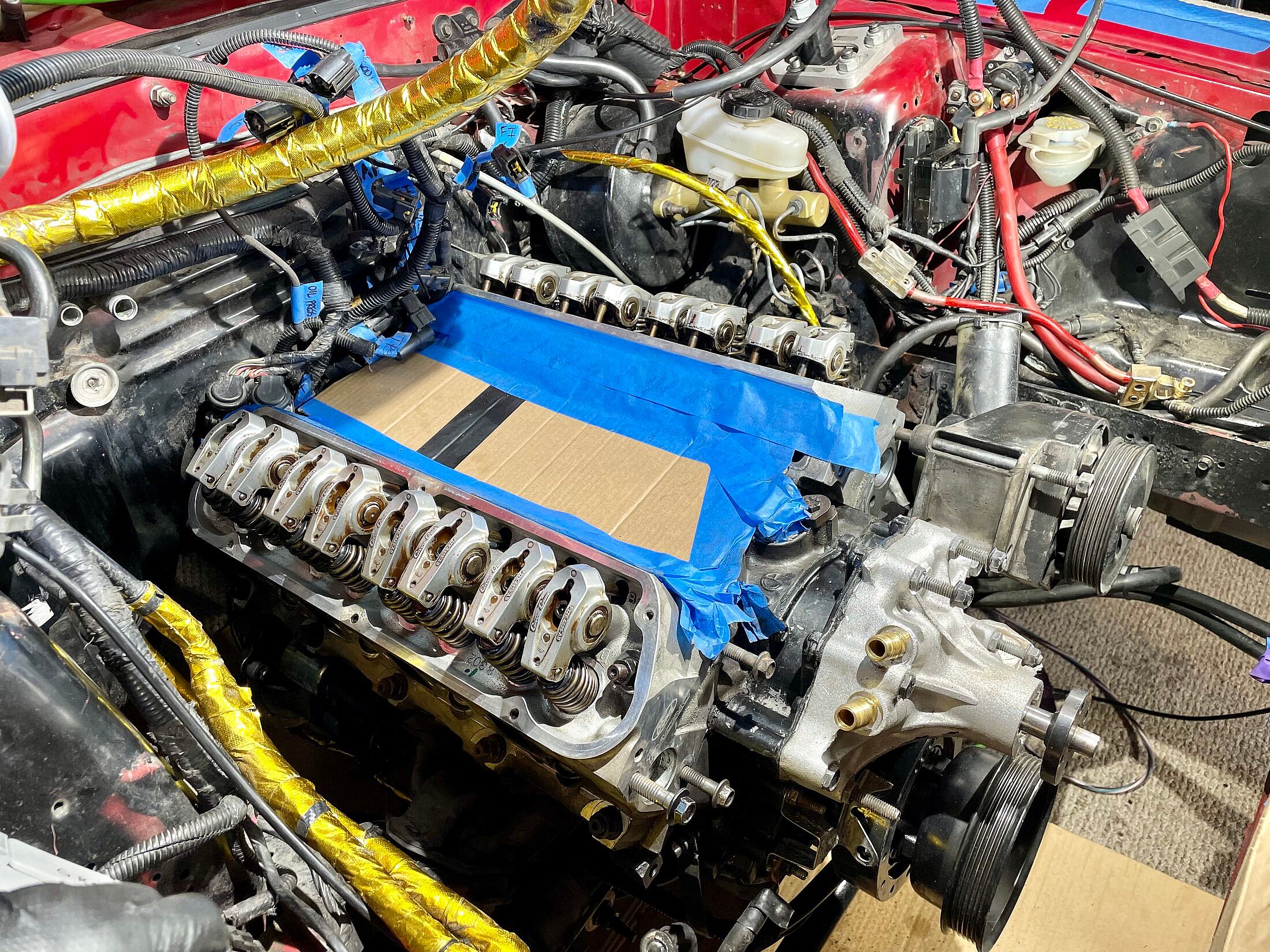

I will be replacing the head gaskets on my motor. I’m going with Felpro 9333’s, that’s what’s on it now and it’s lasted for damn near a decade. I had the motor assembled when I had the stroker kit done, that’s what they used.

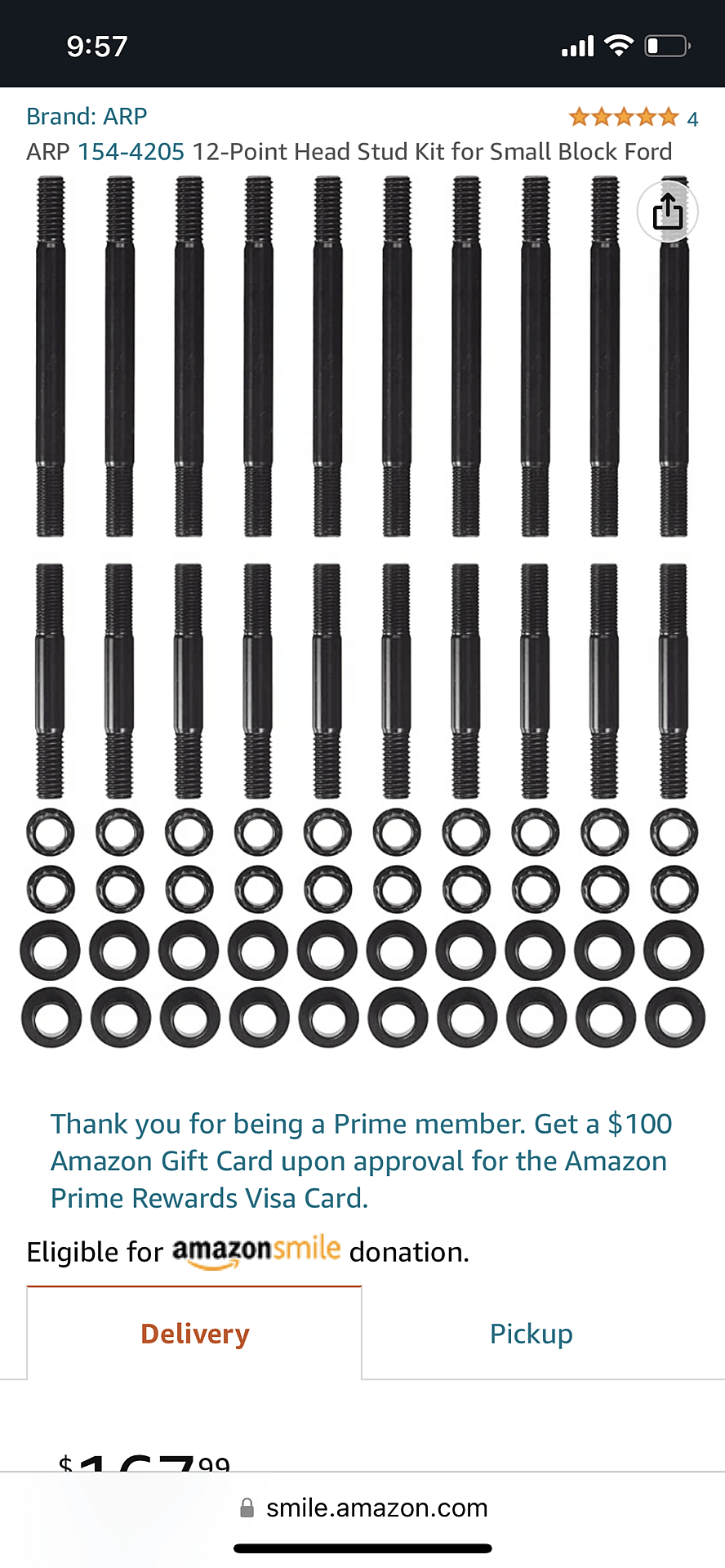

I’m thinking that I’ll just use ARP head bolts, not studs. I won’t be throwing boost at this motor anytime soon, so I think I’m ok with just bolts.

Anything else I should do at the same time?

Also, any good reference material? I don’t mind buying a book if one is better than another for my current needs. I thought I remembered reading a good write up on this website or Corral on the subject, including pictures and torquing procedure. Many thanks in advance, my friends.

Anyway, to the Mustang.

I will be replacing the head gaskets on my motor. I’m going with Felpro 9333’s, that’s what’s on it now and it’s lasted for damn near a decade. I had the motor assembled when I had the stroker kit done, that’s what they used.

I’m thinking that I’ll just use ARP head bolts, not studs. I won’t be throwing boost at this motor anytime soon, so I think I’m ok with just bolts.

Anything else I should do at the same time?

Also, any good reference material? I don’t mind buying a book if one is better than another for my current needs. I thought I remembered reading a good write up on this website or Corral on the subject, including pictures and torquing procedure. Many thanks in advance, my friends.