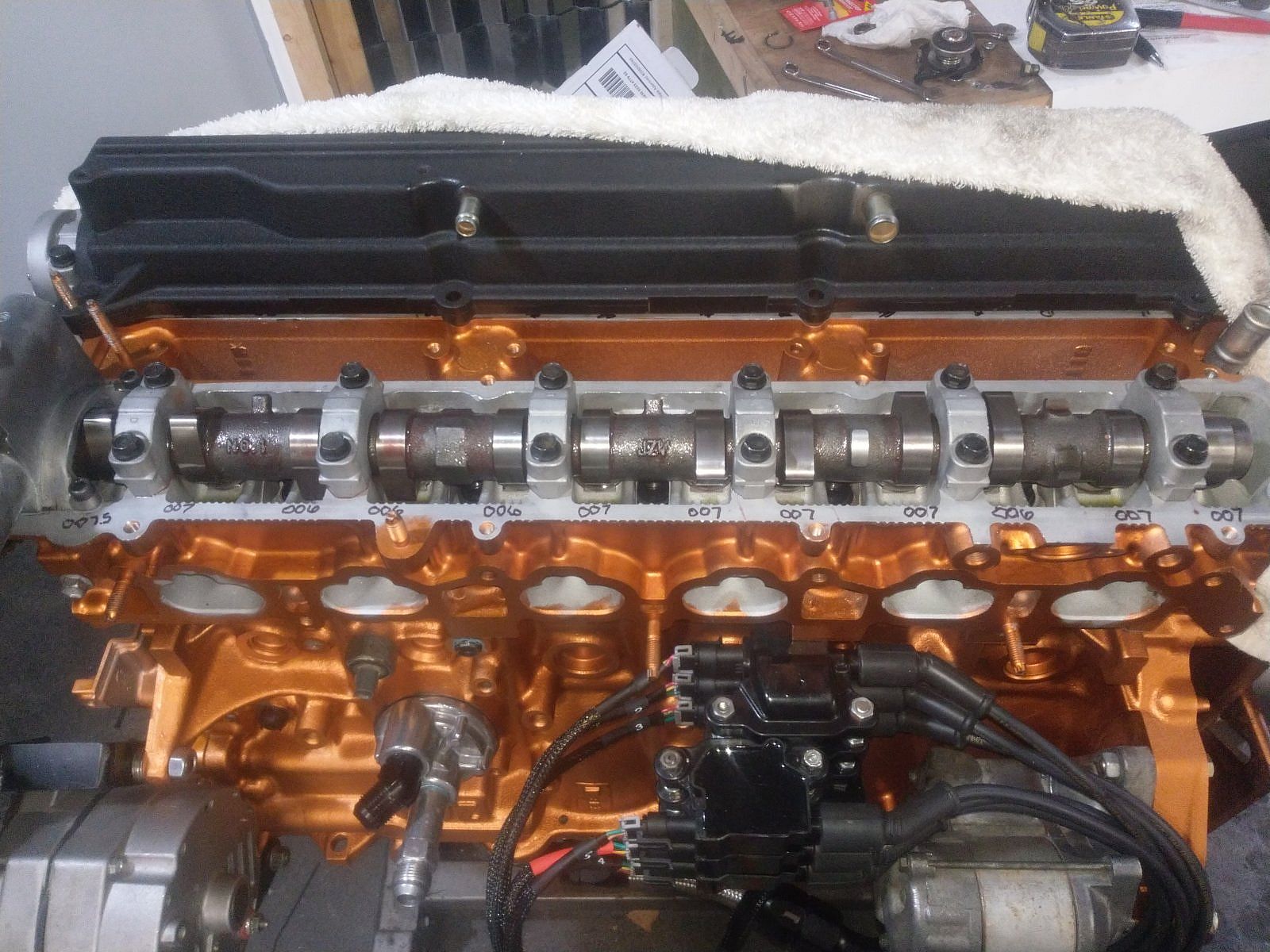

Well I got the new shims installed,....most came into line. One’s too tight, two are too loose. $27.00 to fix it.

Trying to decide how best to prime the engine...I’m thinking that I’m gonna do it on the stand. Since this thing has a crank driven oil pump, the only way to prime the engine is to spin it......with the starter. Since it makes sense to me that it needs to spin fast, I’ll probably do it with the plugs out. It’s one of my conversations with the 3AMD,...his concern that the thing will be hard to prime...and me telling him to go sit in the corner and shut the phck up while I do this.

Obviously, I’ll have to have the front of the engine back on to do that,..and that will have to wait till I get the last three shims from the clueless Lexus parts counter person...Tuesday will be the best case scenario for getting those....Soooo....Maybe Thursday?

I so wanted to be putting this freakin’ engine in the car this Thursday...

It doesn’t matter really...There are weeks of days off left to do the rest of the junk that needs to be done before I can hope to do the restart..Talk about biting off more than you can chew...