I have to work Thursday..it pisses me off that the last week of every month means a 6 day work week. With almost zero exception, every dealer has its crew work w/o a day off the last week of the month....It takes a degree of creativity if you want a day off when it comes to selling cars.

Today,..I had a root canal, AND a tooth extraction.

Who'd be expected to work after having to go through that?

So,...despite having to deal with that pain, I took the time to reinstall the pan,...and reinstall the engine.

* here’s a hint.....I didnt really go to the dentist.

So,..now that I get back the day they tried to take away from me,..I get back to business.

Despite the fact that the mounts were made ( and remade a second time...I needed to move the engine over), I just couldn't resist the urge to do them over again for a third and final time.

The AC compressor hit the sway bar. It didn’t matter whether or not I moved the engine forward or backwards, the little ear that hung down on the compressor was all over the thing, and behind that, the body of the compressor itself was touching. I couldn’t just raise the engine by sticking a shim between the mount and the block like I could have if this was a Windsor, (2j’s bolt to the side) nor could I stick that shim between the bottom of the mount and the K member ( when I did that, it raised the mount stud up out of the bottom of the notch in the K member ).

So I had to add thickness to the bottom of each mount ( 1/4” on one side, 3/16” on the other) ...the engine didn’t sit as level as I wanted it to,..this fixed it. Both mount studs had to be cut off, drilled back out, and then new holes had to be drilled through what amounted to almost 1/2” thick steel....that had been welded and ground, welded and ground,... and welded and ground numerous times...to say that the metal was hard from all of the trial and error heat treating I had done to it...........yeah.

They're pretty hideous to look at...you’ll never see a close up of them.

When that finally was done I put the engine in. This makes 4 times. getting to the transmission bolts on top is impossible, ( because the engine is almost jammed against the firewall.) tightening the converter bolts is a giant pain in the ass ( because that custom made, leaky ass rear sump pan, blocks being able to get to them).

But you know what?....it sits where I want it to. Like I want it to, and despite the challenges, they can be overcome.

The drive shaft yoke has a little more travel distance in the tail shaft as compared to how it was with the Monster v1.0, the pan don’t hit nothin, and the compressor eeks by the sway bar. It cost me the whole day though.

There are more hurdles to jump now that the damn thing is in.

#The lower water outlet runs right into the AC fitting going into the compressor...I gotta make a jinky-doo so that it’ll get past it ( means I gotta have that housing welded with an offset to clear) Both the inlet, and outlet have to be made to fit.

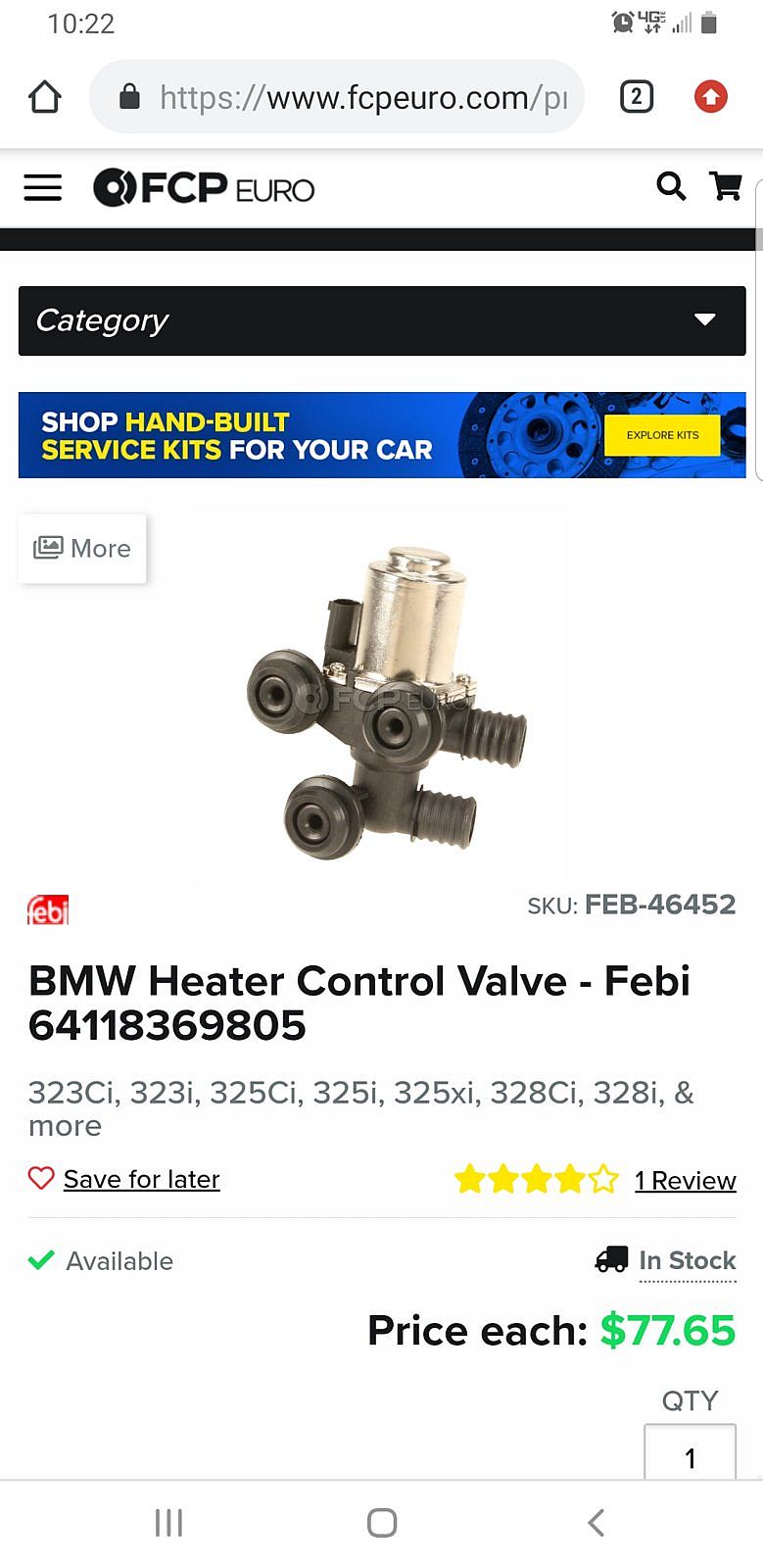

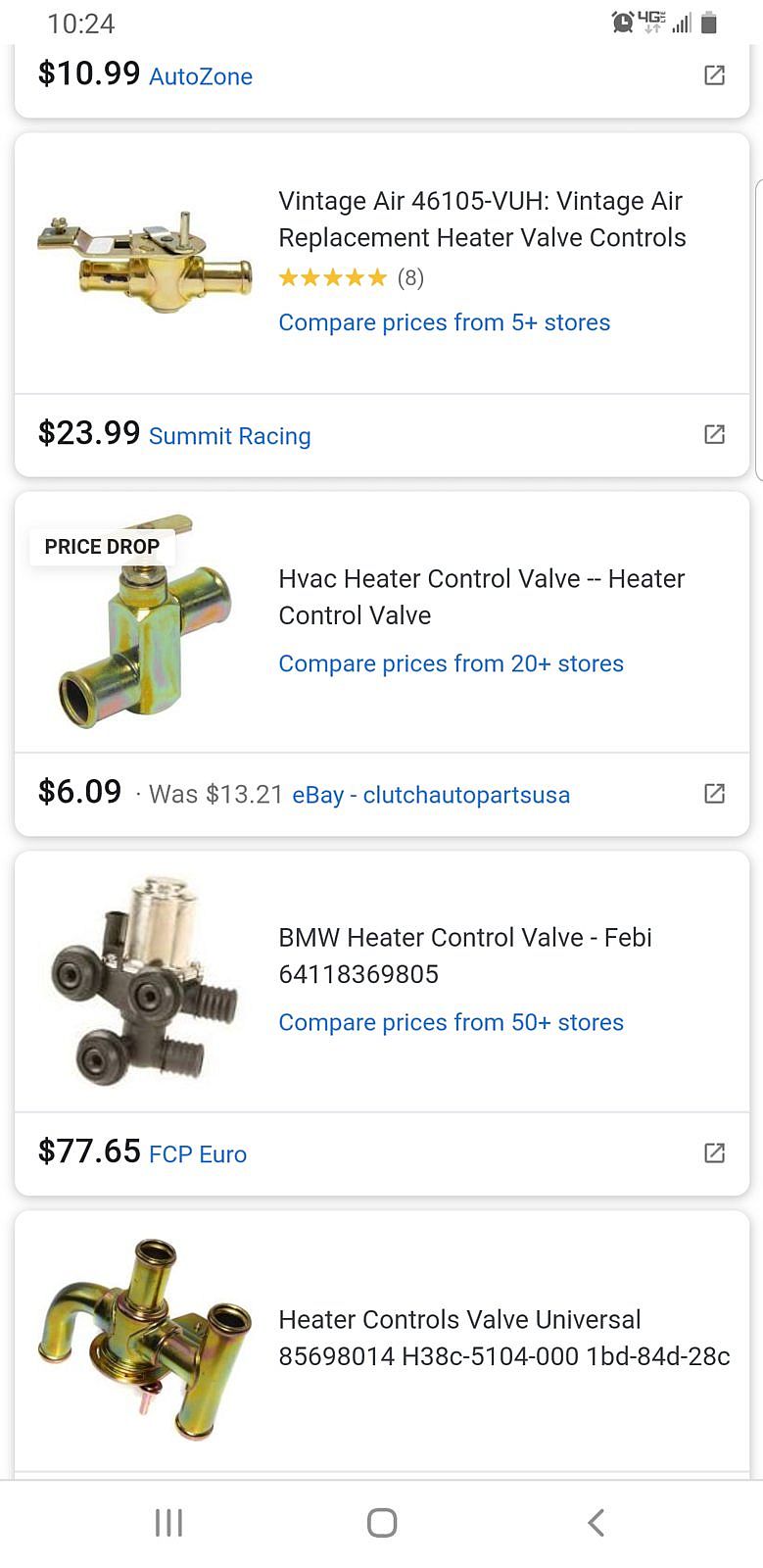

# The water pump has an inlet to allow for bypass water to come back to it. In the car that the engine came in, a tube ran under the exhaust header to one of the heater outlets and it got that water from there. My heater has a control valve on it that blocks water flow when the heater isn’t on, so now I have to add some sort of “ summer/ winter” control valve so that I can by pass the heater in the summer months, and allow that water to move through the engine.

# I pulled all of the wires that were hanging into the engine compartment back through the firewall. i have to remove the ones I don’t need, keep the ones I do, and add even more, now that I’m changing the thing over to COP/ SEFI/ knock sensing/ VVTI. Tracing those wires back to the ecu will be the same giant pain in the ass that they would be in a stock wiring harness.I can’t even see the firewall grommet without getting all bent up under the dash with a flashlight.

# I’ve got a whole bunch of work at the rear of the car, I have a fuel cell to modify and mount, a water reservoir for the A2W to mount. heat exchangers to mount, wire and plumb, and a floor to rebuild. I’m so tired of dicking with the engine, I believe that I’ll move to that next...

As the world turns.....