I have the startings of a oil pan..

I'm pretty proud of myself here..see the front " hump"? It's 3/16" thick and it fits like it was molded.. But it wasn't.

It was bent by me..in a vise. One little tweek at a time..

Needless to say, doing things this way takes for freakin ever...and I spent the whole day to get the engine separated, the stock pan off,..the engine mounted on a stand,..the pieces parts bought from lowes,..and get to this point.

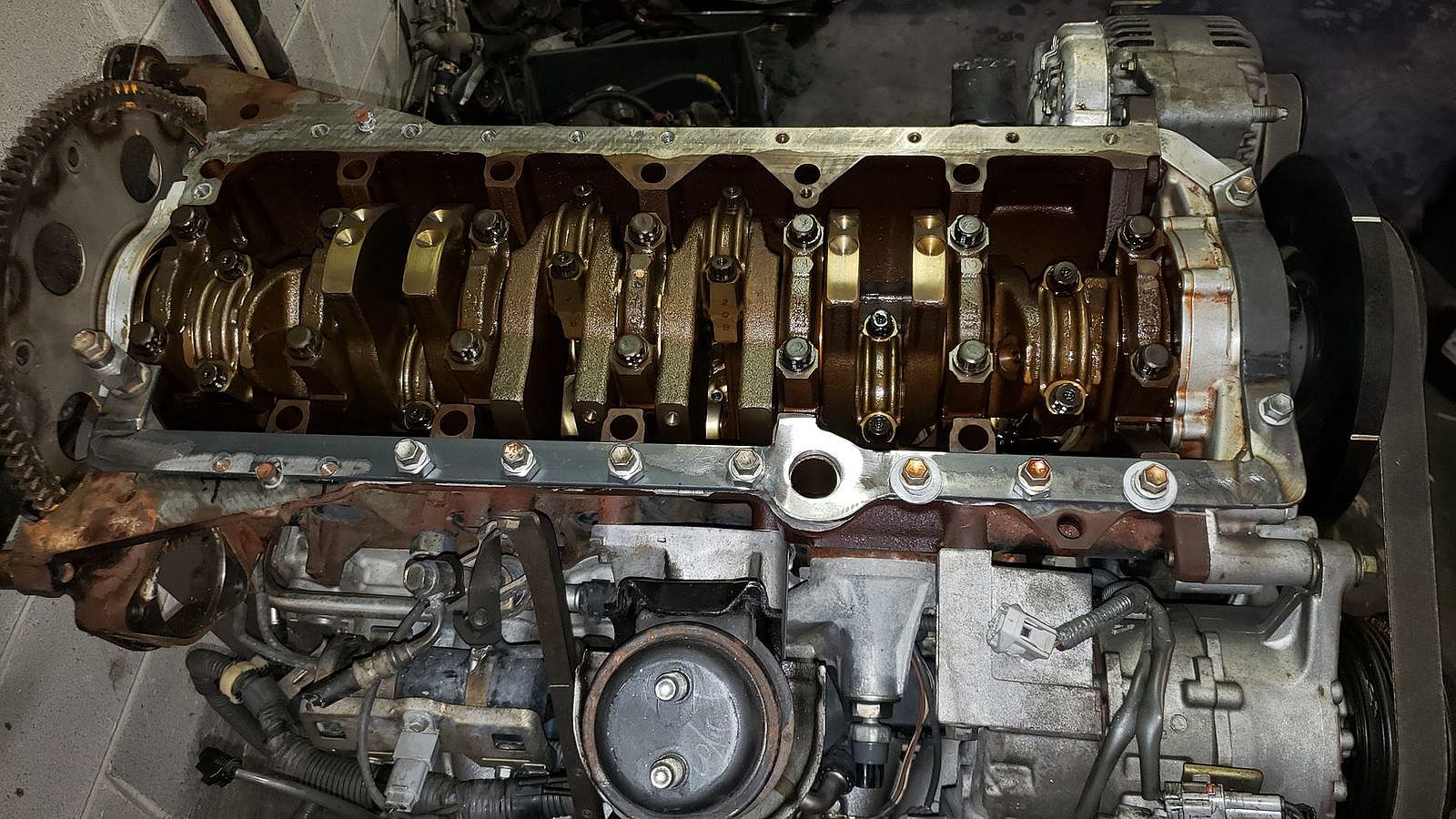

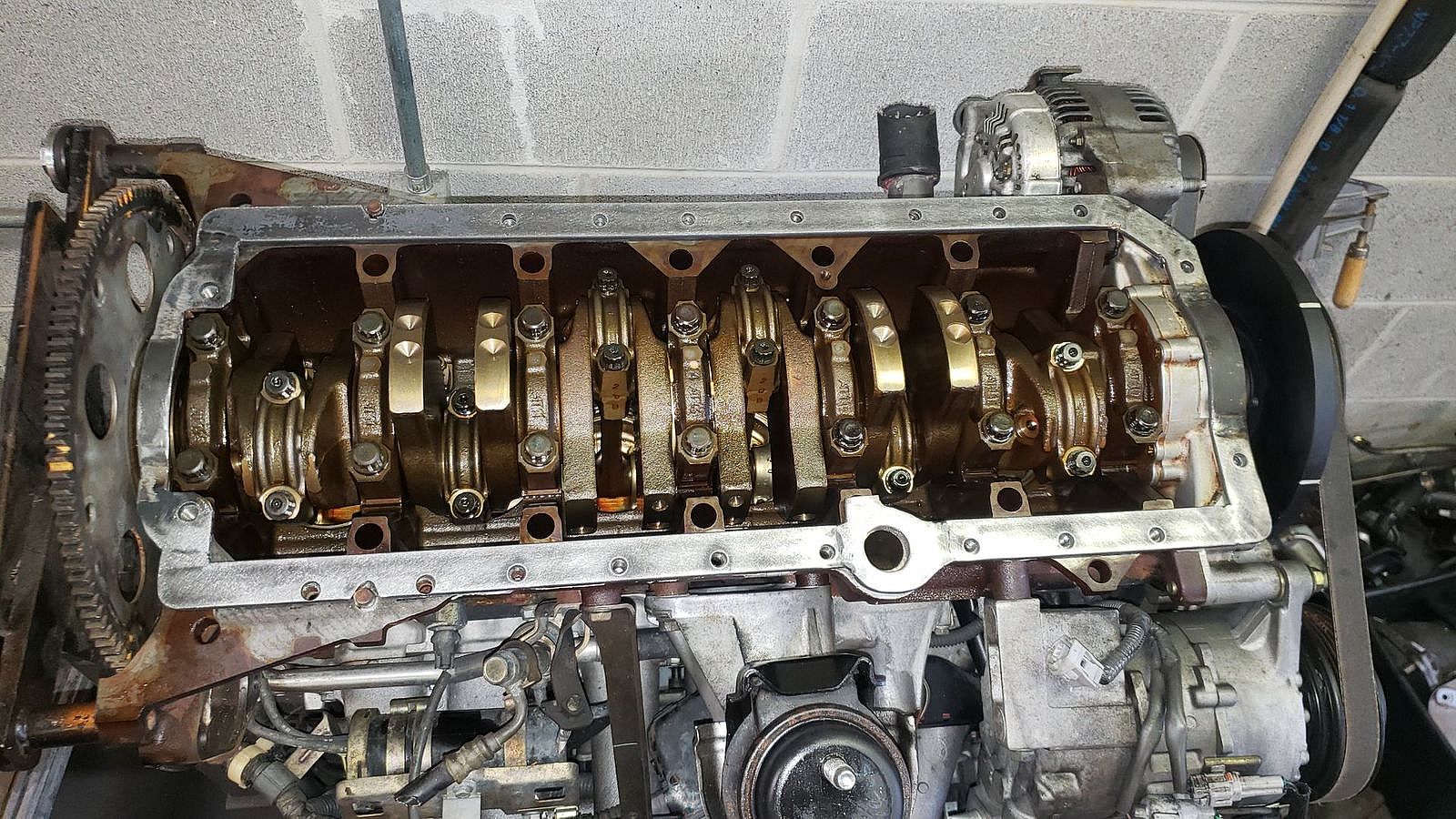

The good thing is this engine looks perfect..no sludge of any kind. The oil screen was clean, save for a tiny bit of sucked up silicone from something in its past....

The bad thing is that I hate having to build a pan using an assembled engine. Despite my best efforts to try and keep weld spatter out of the engine,..I still worry that some little ball,of hot molten steel might get past me.

I'm confident that I'll be able to build a pan for this thing. It'll be epic.

Then transmission adapter is getting closer to being solved..after getting the factory stuff separated, and putting the engine on a stand I'm thinkin.........." Why couldn't I do the same thing I'm doing to adapt this engine stand to the 2j? If I buy like 1/2" bar stock, drill one end to fit the 2j block,.and wherever the 4r70w bell pattern ends up I cut, drill and tap that leg . So,..I make 5or 6 legs.. I bolt them to the back of the block..I bolt my 4r70 to the legs. Once I get everything adjusted,...I remove the 4 r 70, and make interconnects that tie each leg together. They get welded to each other. In essence, I build an erector set that looks like a spider web of sorts.

All I gotta do is measure some sht...I don't need no stinkin cnc...And I'll do this for less than a couple of hundred bucks.

I do need a machinist with a lathe though.

The spacer that hubs off of the 2j crank, and steps up to my converter hub OD is beyond me.. But putting a 4r70 behind a 2j isn't.

yourself" classes.

yourself" classes.