Well add another 300.00 to the compressor purchase for lines and related stuff, and you have a complete system.

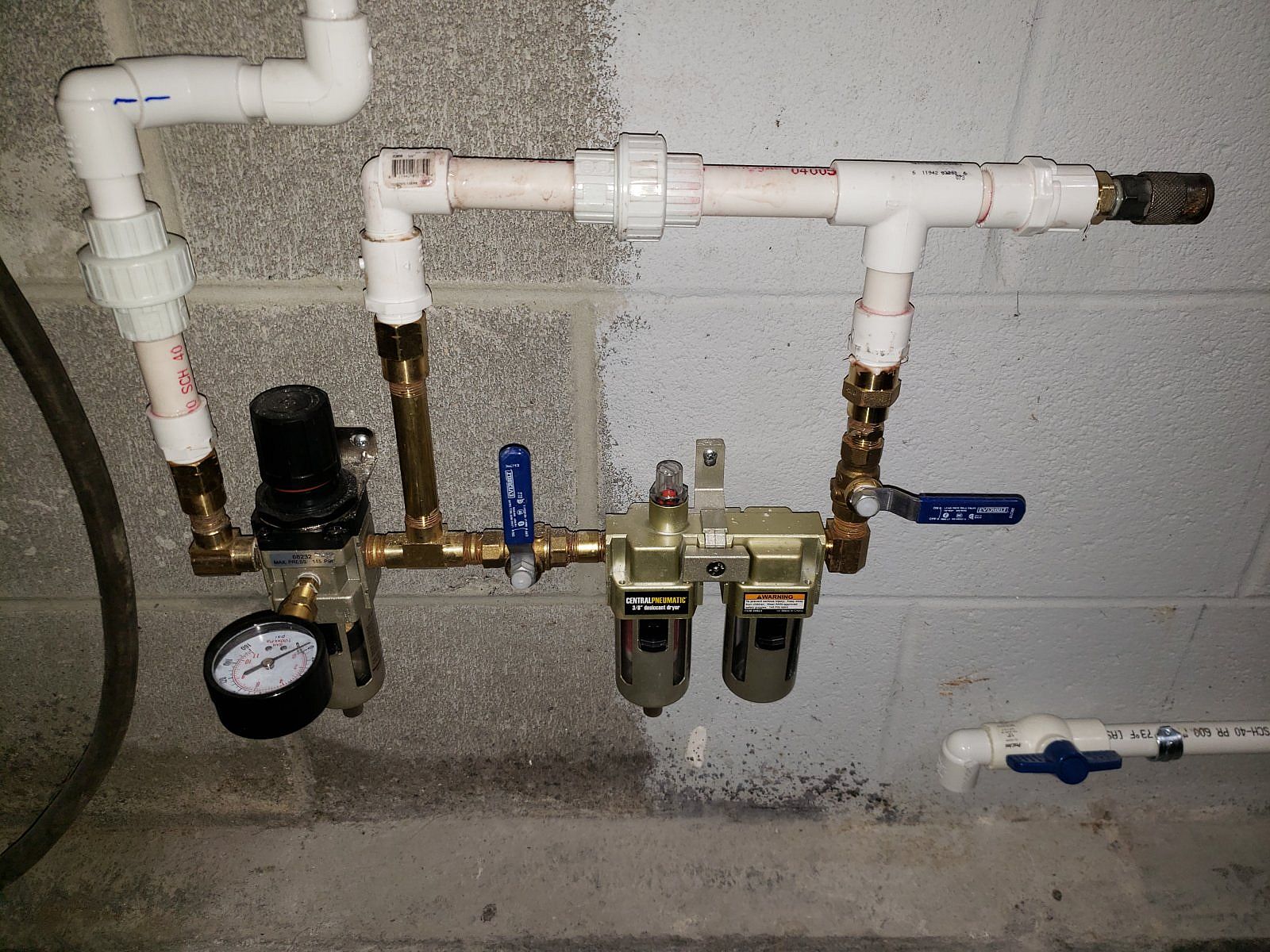

Something must be up with CPVC, because Home Depot stocked nothing in the way of fittings to use that stuff. I ended up going with standard ol' schedule 40 PVC. I bought (3) 10' sticks, and a buttload of fittings. Then, I went to HF, and bought their regulator/filter, and a combo filter dryer.

It is my intention to not run the air through the filter dryer all of the time, so I'm gonna split the air supply into two different paths, and use shut off valves to divert it one way or the other. 99% of the time, I'll just run the air through the regulator/ filter, and whenever I'm painting something, I'll route the air through the extra filter/dryer thingy.

Now I know that that seems like a lot of bullsht to go through just for the 1 percent of the time I may be painting something, and if I didn't have a paint project looming on the horizon, I wouldn't have gone through the extra money and headache to do this....

But I DO have a paint project looming ahead...and it only added 100 bucks to the project,.....So what the hell,...May as well do it...

Right?

The part where I can't wait to show is the "contraption" that is the air line manifold...35' of air line " boxed" into a 4'x3' space.

The line runs over and back a couple of times, and up and down a couple of times after that..with intersecting drain taps, all running into the traffic cop that routes the air this way and that,.......The freakin thing looks like a Dr. Suess musical instrument that any self respecting Who, living in Whoville would be proud to own...I believe that I've created a Rink dinky flu- fluter.

I've switched days off from Monday to Tuesday. I ran out of junk to finish the RDFF, so I'll have to postpone that particular picture till tomorrow.

You lost me after "the tail lights I like".

You lost me after "the tail lights I like".