If its puking out more than a quart of oil every 1000 miles, then the rings haven't bedded into bores, that is a gradual processas modern bores are too smooth for oil retention, especially if someone has only targeted average Roughness (Ra) instead of Rvk, Rk, and Rpk combination that comes from a good plateau hone. . With modern chromium rings , not the ductile iron, that process can take a while. Target Rvk should be 24, Rk, 20, and Rpk 5. Ra is not a measure I'd use on a modern engine anywhere, not on the head gasket, not on the cylinder walls, but I'd expect your cylinder walls are a super slick 10 Ra. If its rougher than all those figures by a factor of 1.6, its getting too rough, and you start to see oil at the bottom of hill after a long run, or the blues on start up. s on start up.

I'm sure you've got issues since you haven't done a 1000 miles yet, but as you know, the operator is the plateau hone for a performance engine.

As long as the liners are still true, then if the moderate boundary layer needed has gone west, (and you haven't got other issues, like the late 90's Modular and LS Chev 1500-1800 rpm shallow compression heighet Zollener piston slap), it all comes from a really smooth bore and need for a little more valley depth in the bore from the core roughness.

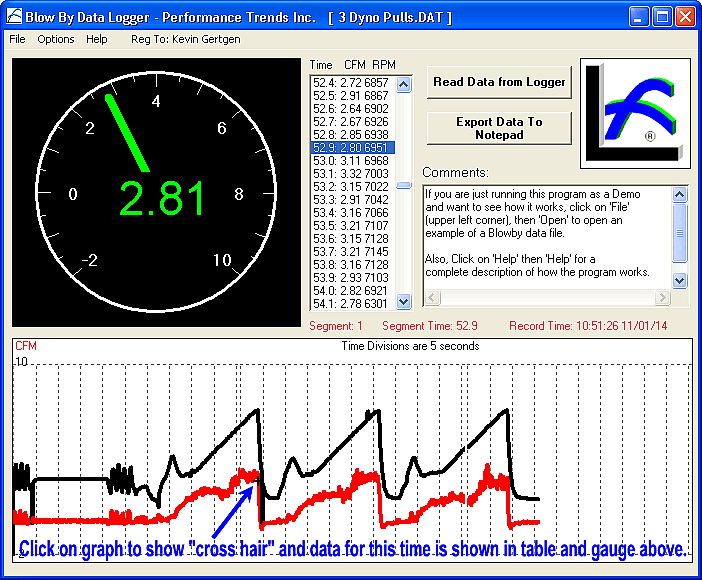

If your having blow by, then you know the peak levels have already been given, generally 3 cfm at 5500 rpm or maxumum torque, which on a turbo will be at 3000 rpm, and the same as at 5500 rpm.

With 3 cfm going basically to the crankcase and to the rocker cover, water in oil readings are only an issue for engines with blown head gaskets, or porus head castings, or wet liner engines with a slipped liner. Then, they would go off the chart with milky oil the symptom, basically more than 50% of the blow by would then be water. After a varied bed in, weekly or monthly 1000 miles of running, you might have close to zero oil loss, but a constant 3 cfm blow by is what a normally aspirated engine makes. Turboed, it'll see that peak and more, much more often. Guides, rings, ( through the piston ring gap, and piston rings ) and the additional blow by from a 1.6 boost ratio, and cfm goes up primarily another 40% by turbo shaft, both air compressors, and that extra from the valve stems. In total, these components can be responsible for as much as 40% of the crankcase blowby. The combustion process is largely wasted in a piston engine through heat, but the cracking process of converting gasoline to heat and movement also liberates a lot more steam in a turbo engine. But none of that steam is anything other than evaporative emission blow by, what comes back through the injectors via fuel stand off, and rings, ring gaps, valve steams, then the whole three parts of the turbo. On a turbo engine, that can be a crap ton.

I'm sure you've got issues since you haven't done a 1000 miles yet, but as you know, the operator is the plateau hone for a performance engine.

As long as the liners are still true, then if the moderate boundary layer needed has gone west, (and you haven't got other issues, like the late 90's Modular and LS Chev 1500-1800 rpm shallow compression heighet Zollener piston slap), it all comes from a really smooth bore and need for a little more valley depth in the bore from the core roughness.

If your having blow by, then you know the peak levels have already been given, generally 3 cfm at 5500 rpm or maxumum torque, which on a turbo will be at 3000 rpm, and the same as at 5500 rpm.

With 3 cfm going basically to the crankcase and to the rocker cover, water in oil readings are only an issue for engines with blown head gaskets, or porus head castings, or wet liner engines with a slipped liner. Then, they would go off the chart with milky oil the symptom, basically more than 50% of the blow by would then be water. After a varied bed in, weekly or monthly 1000 miles of running, you might have close to zero oil loss, but a constant 3 cfm blow by is what a normally aspirated engine makes. Turboed, it'll see that peak and more, much more often. Guides, rings, ( through the piston ring gap, and piston rings ) and the additional blow by from a 1.6 boost ratio, and cfm goes up primarily another 40% by turbo shaft, both air compressors, and that extra from the valve stems. In total, these components can be responsible for as much as 40% of the crankcase blowby. The combustion process is largely wasted in a piston engine through heat, but the cracking process of converting gasoline to heat and movement also liberates a lot more steam in a turbo engine. But none of that steam is anything other than evaporative emission blow by, what comes back through the injectors via fuel stand off, and rings, ring gaps, valve steams, then the whole three parts of the turbo. On a turbo engine, that can be a crap ton.

Last edited: