Let me start by saying that transmission work is time consuming, and that if the trans is out of the car by God do the valve body then and not under the car... like an idiot... like me.

I did the transgo recalibration kit in the 44R70W I opted for all the firm shift options just short of "race car" it was not hard to follow the directions and tackle each step one at a time. I honestly think some guys make a bigger deal out of this than is needed.

I did not get pictures, I am filthy my work area is clean but only because I threw away the cardboard I used to stop a petrol disaster... I have more transmission fluid on me than the cardboard did I think.

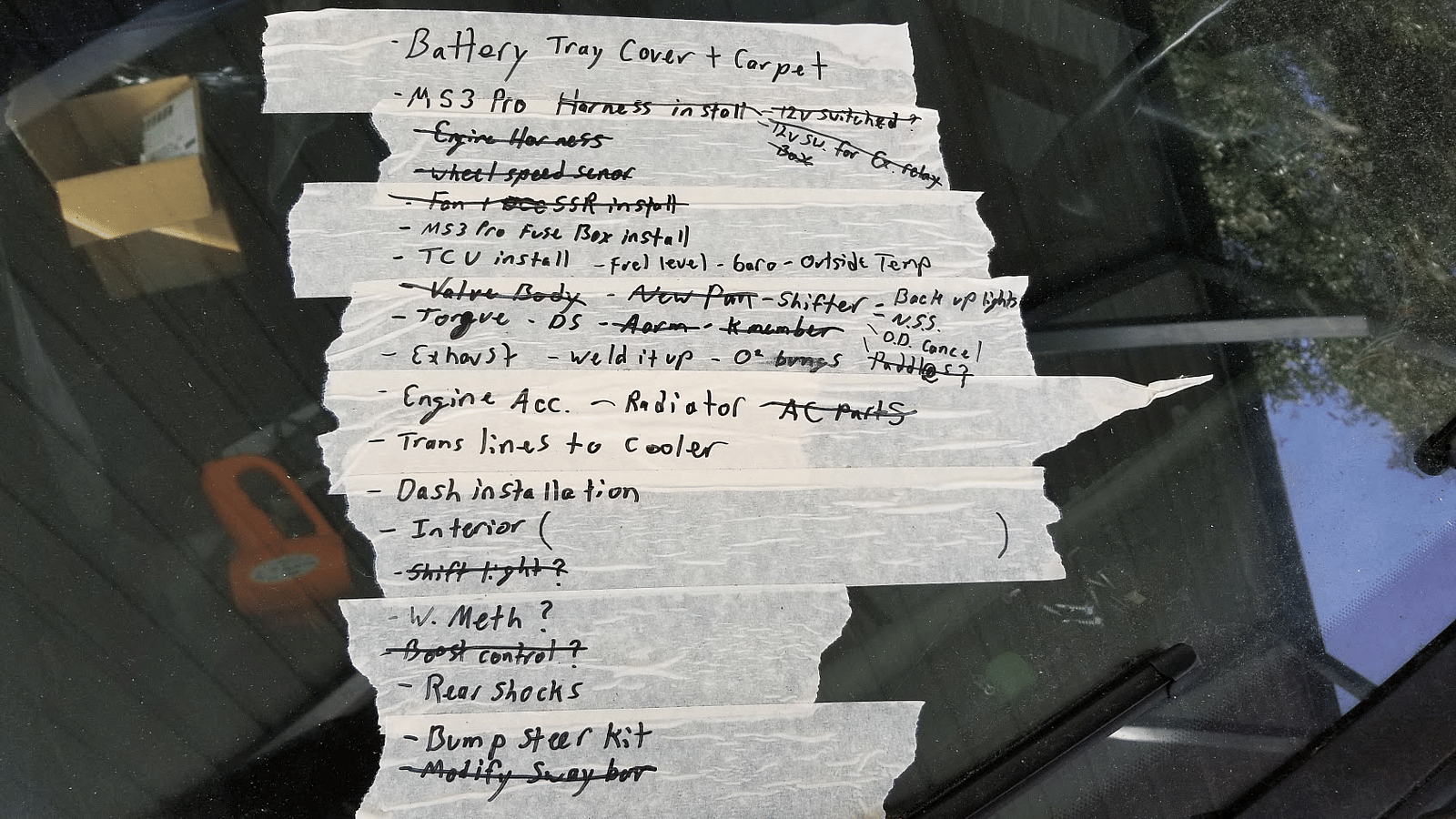

For me this is a major hurdle I just crossed, next up is to finish off the engine bay and then tackle the transmission harnesses.

If you are wondering the transmission looked ok inside and the fluid did not smell burned. I did have stuff on the magnet in the pan but the likelyhood of this trans ever having been serviced is nil.

I did the transgo recalibration kit in the 44R70W I opted for all the firm shift options just short of "race car" it was not hard to follow the directions and tackle each step one at a time. I honestly think some guys make a bigger deal out of this than is needed.

I did not get pictures, I am filthy my work area is clean but only because I threw away the cardboard I used to stop a petrol disaster... I have more transmission fluid on me than the cardboard did I think.

For me this is a major hurdle I just crossed, next up is to finish off the engine bay and then tackle the transmission harnesses.

If you are wondering the transmission looked ok inside and the fluid did not smell burned. I did have stuff on the magnet in the pan but the likelyhood of this trans ever having been serviced is nil.