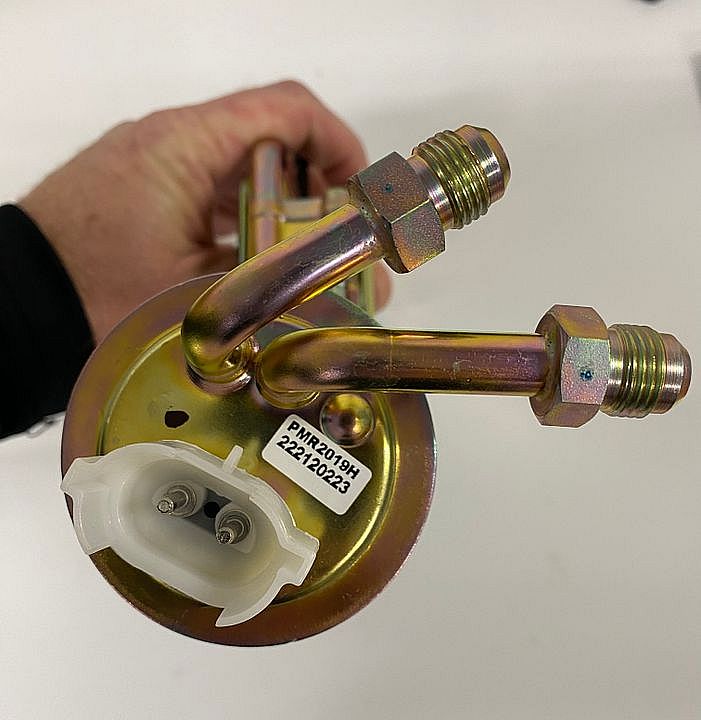

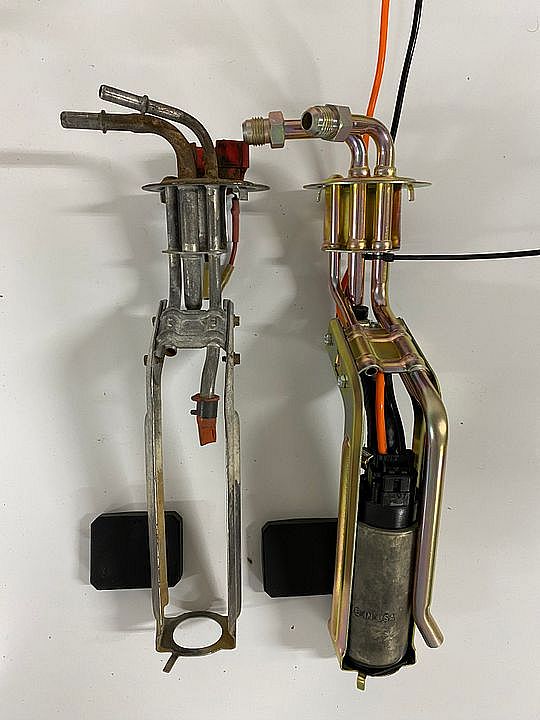

Got the Pro-M hanger and as far as I can tell is it a quality piece.

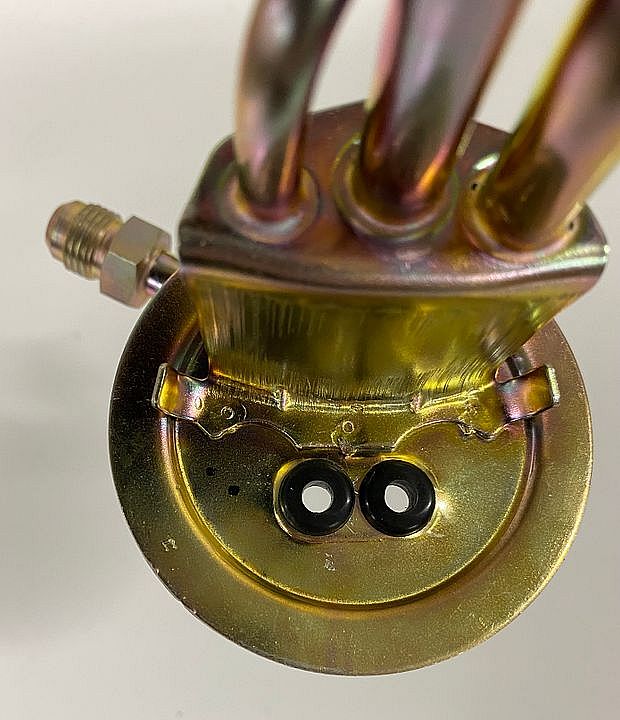

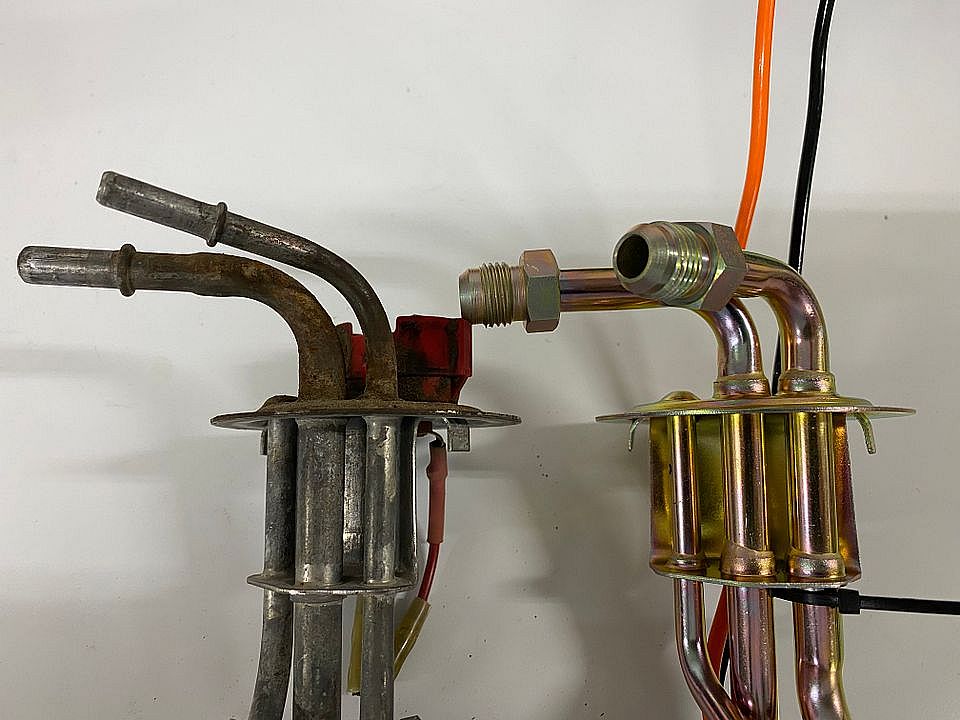

I got the factory connector off by drilling the rivets on the bottom side of the flange and then opened the holes up to 9/32" and was able to install the grommets with some persuasion as I wanted them to fit as tight as possible:

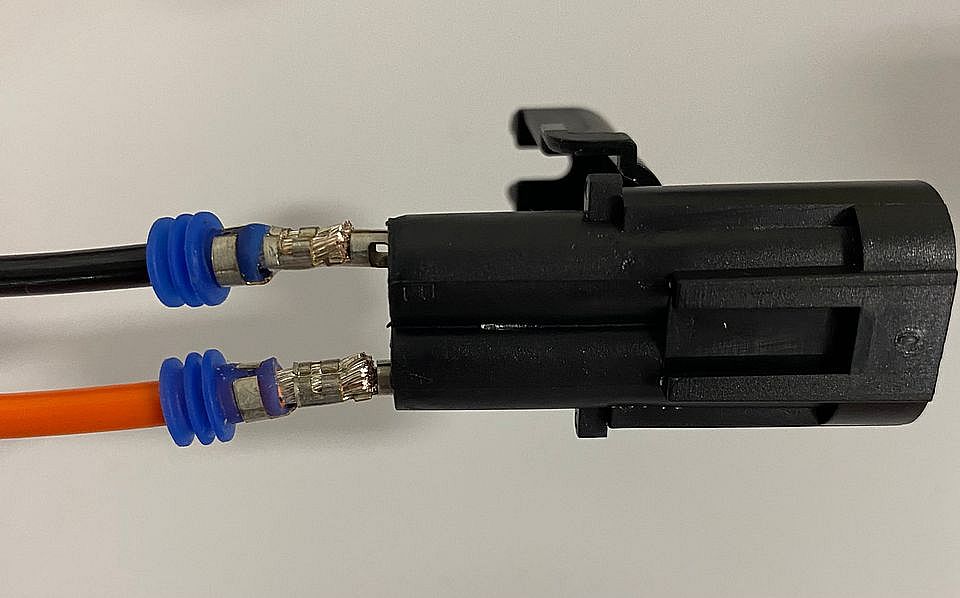

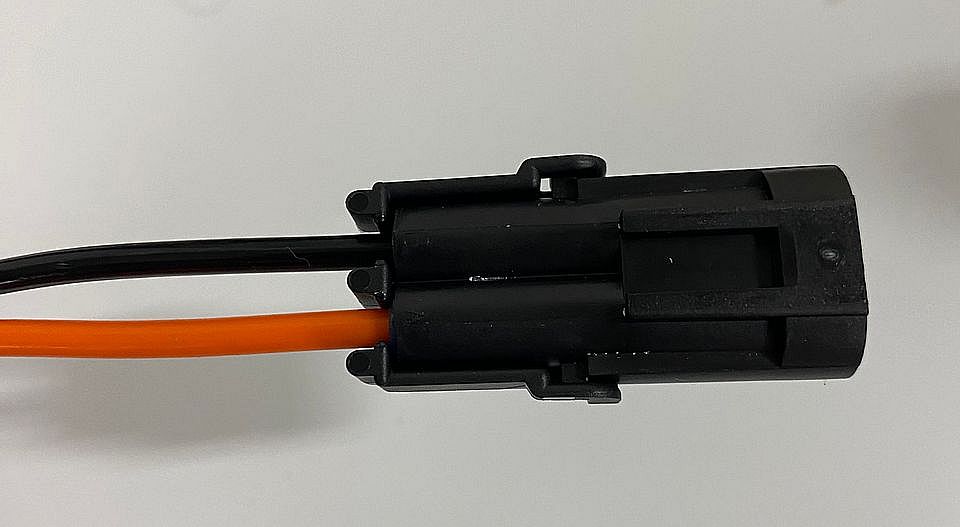

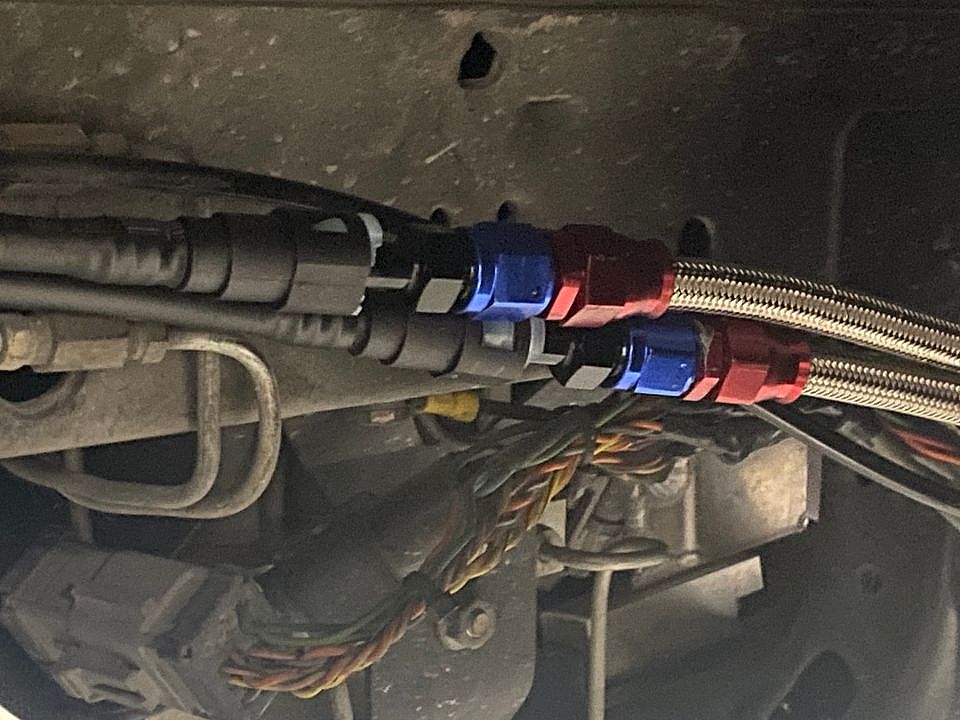

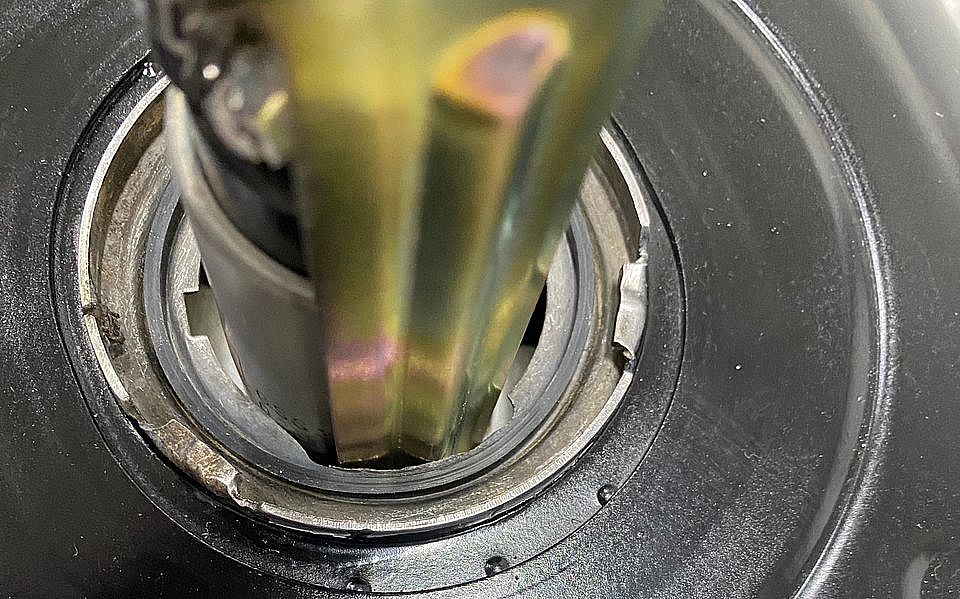

Got the fuel pump connector made up and popped that on the pump and fed the wires through the grommets:

Laid out the wiring path for the pump and sending unit on the tank and made the cuts on the fuel pump wires for the Weatherpack fitting that will be under the car so I can take the tank out at a later date with no issues:

Having the correct crimping tool is a must with these fittings. I have and highly recommend the following crimpers:

Sargent 3302 WPCT Crimping Tool for Aptiv Weather-Pack Terminals, 12-10 Ga.

Sargent 3301 WPCT Crimping Tool for Aptiv Weather-Pack Terminals, 20-14 Ga.

I get most of my stuff off of Waytek Wire (

https://www.waytekwire.com/) as they seem to have good prices and they ship fast.

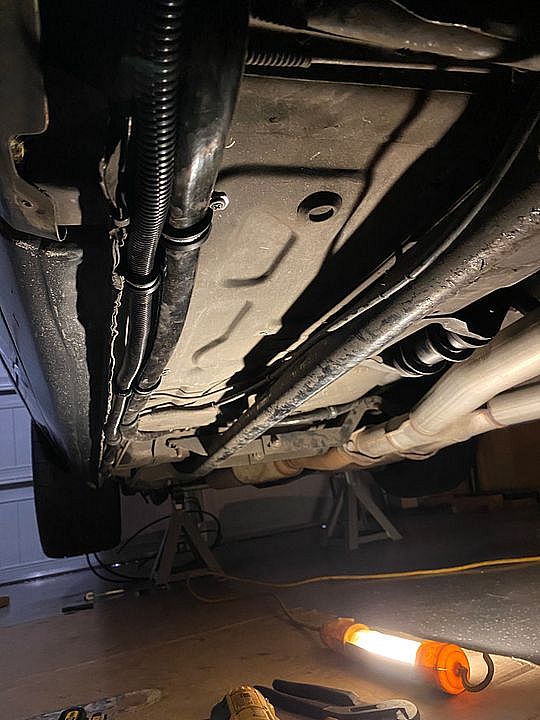

Mixed some epoxy up and applied that to the wires and grommets on both sides of the fuel hat flange and its supposed to get down into the high 30's this evening so that is curing in the house overnight.