Obsessing way too much over every little detail is the regularly scheduled program in this thread.

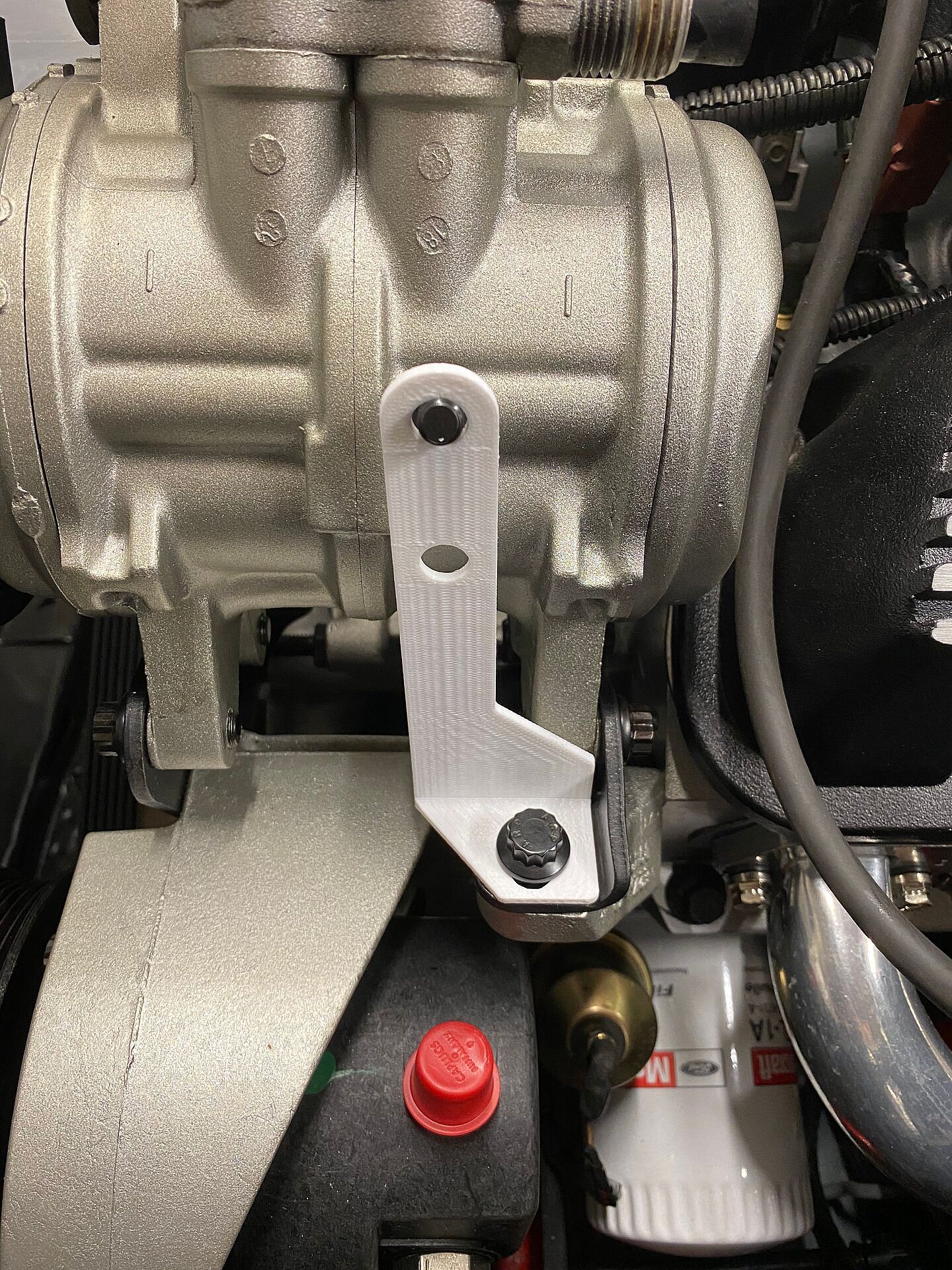

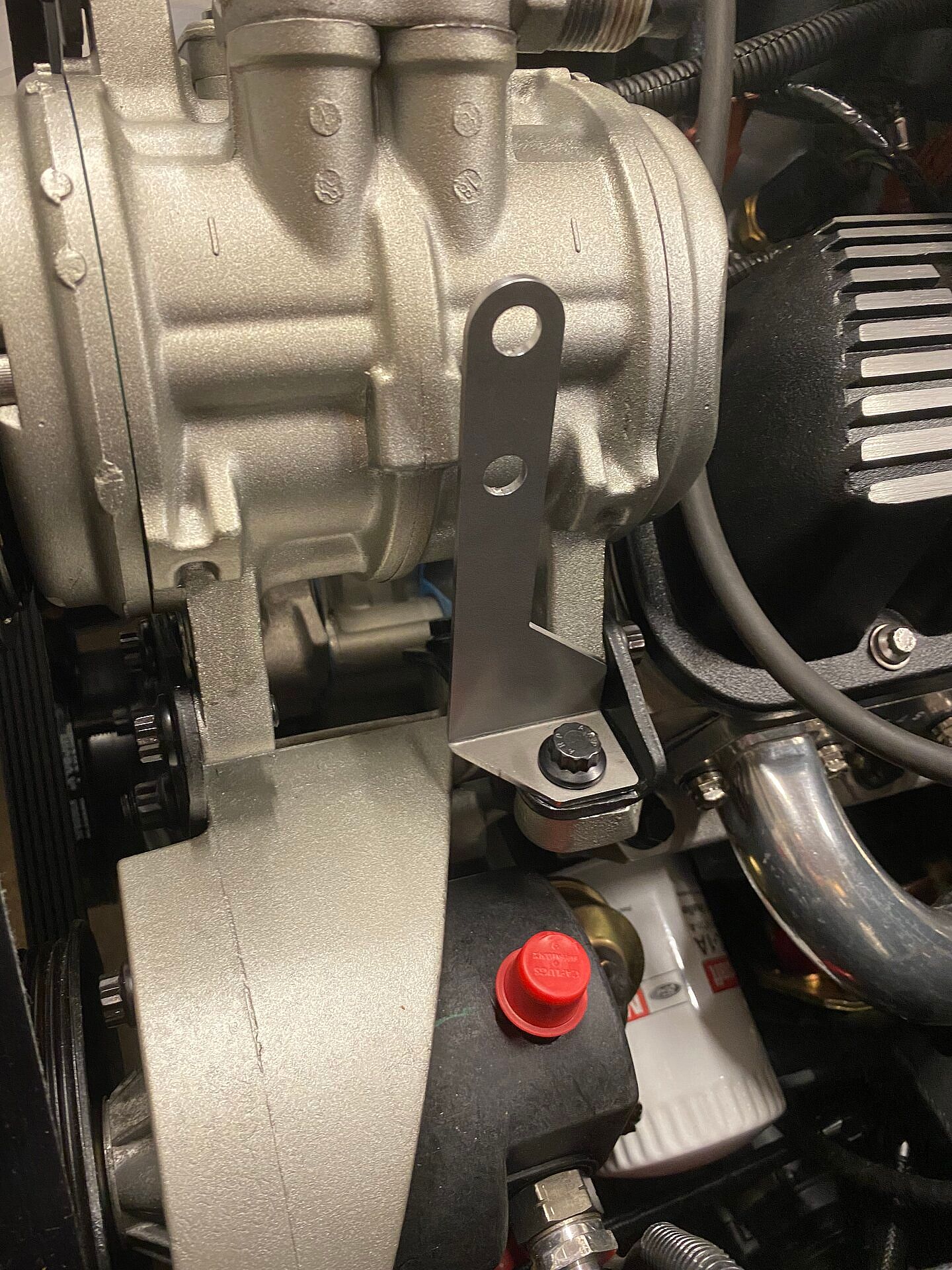

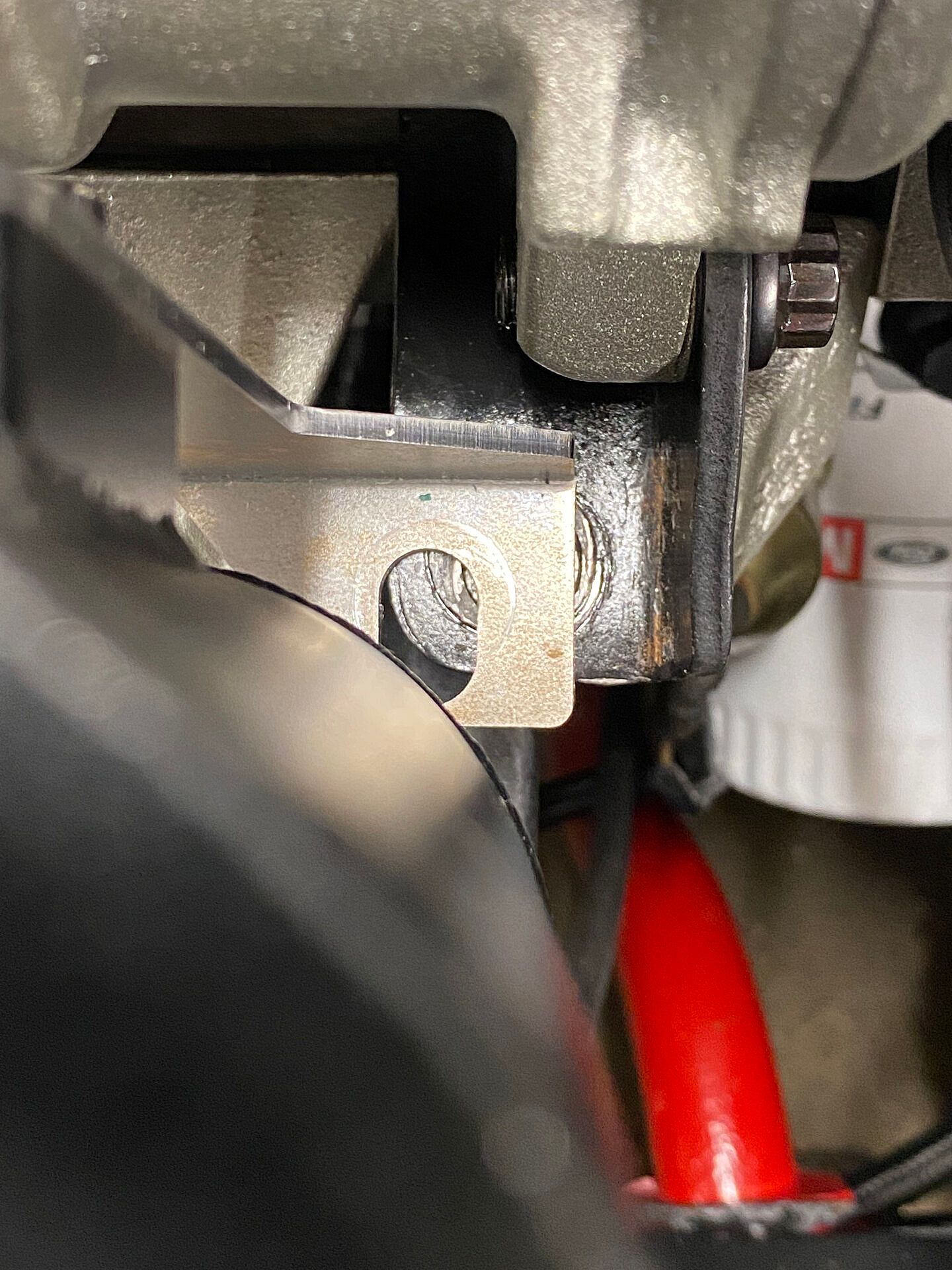

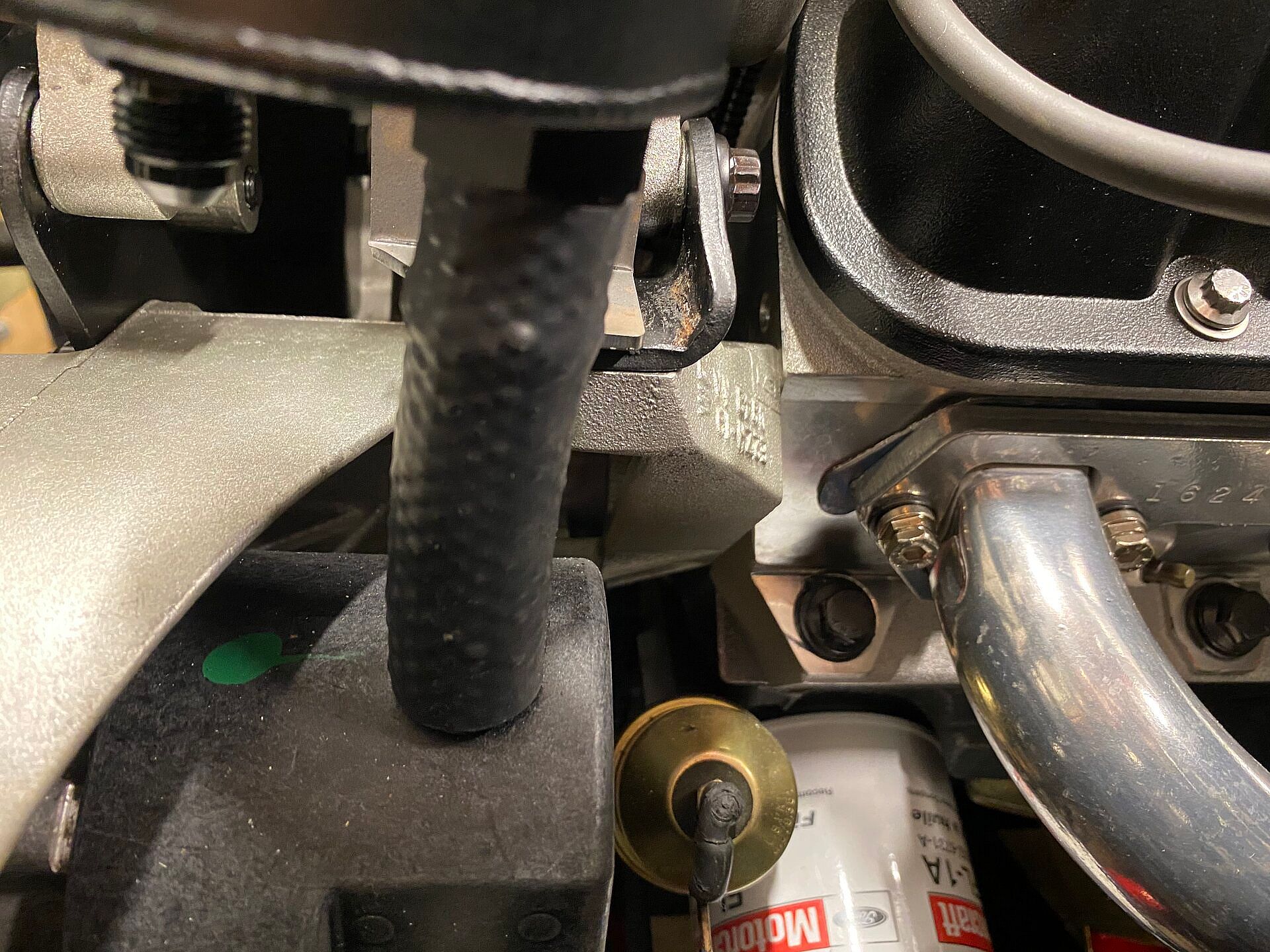

I don't necessarily think this is obsessing. This is what I do all day long, so it's not as complex as I make it seem to be. 5 mins of modeling, toss it on the 3D printer. Test fit, 5 mins to make a cut program, 30 seconds of active cutting and toss it in a brake and bend. Done. Most of that done while sitting in AC sipping a coffee. In about 3 months when we buy a 3D printer capable of printing metals I can just model and print it in 316L and call it a day.

Fabricating is fabrication. I just happen to have access to different methods of doing so. I like my methods.