Here's a dumb/theoretical question:

I wonder if there would be any benefit to increasing the vacuum canister volume for combos with crappy overlap?

Sorry... random thought.

I've heard of guys doing this either running a vacuum pump, or a larger supplemental canister.

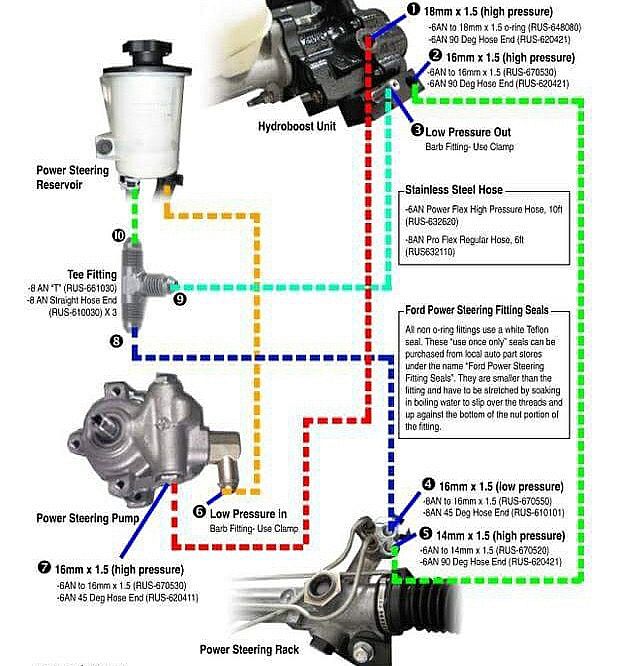

In my case it doesn't matter. With the hydroboost, all I need vac for is the HVAC system, FPR and the EGR. Eventually the EGR will be gone as well when I go with the Megasquirt. I'm leaving that stuff in just in case down the road MA does anything crazy with vehicle emmissions and I need to hook some of the stuff back up. I'm not too worried about the extra 1/2 pound of plastic weight when I cruise around to get a coffee or hit a car show.