HotFox

15 Year Member

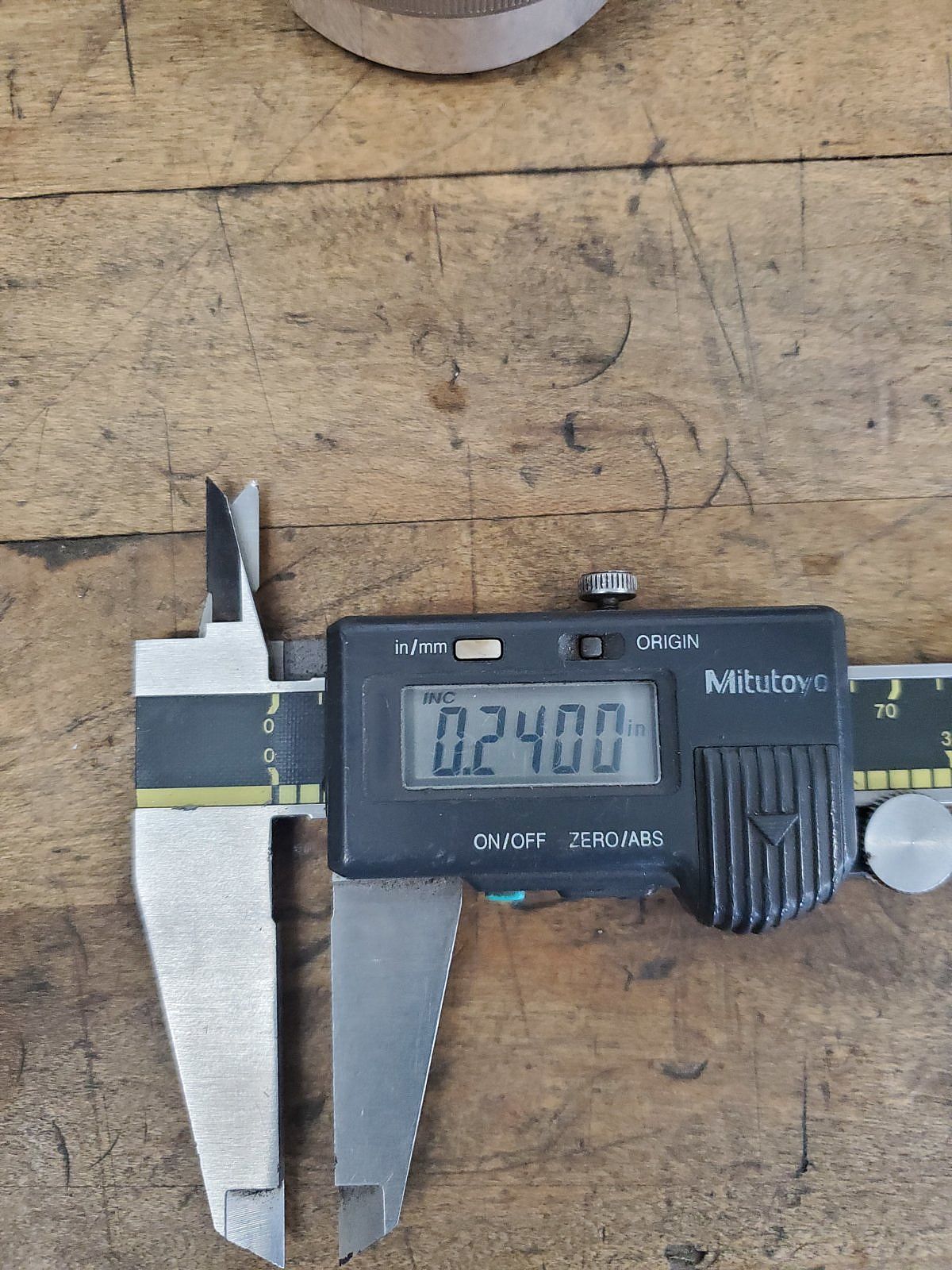

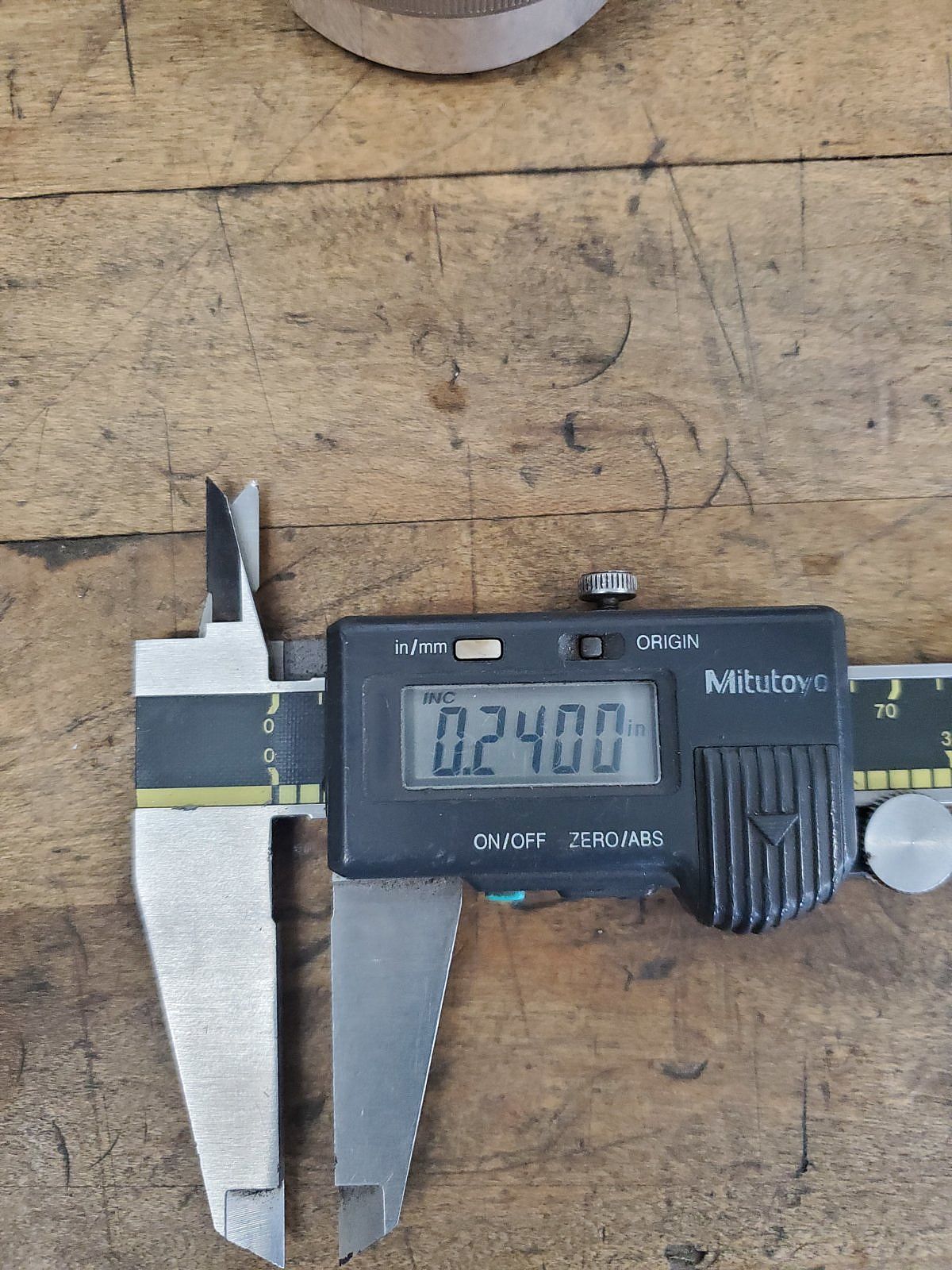

I have 2 styles, the blue would push on the top of the seal and probably be ok unless you were careless. I got dims for both but am just posting the silver as the double step grabs the outer body better. Diameter may vary depending on size my sample is .623 OD for a 11/32 stem.

^^^

^^^