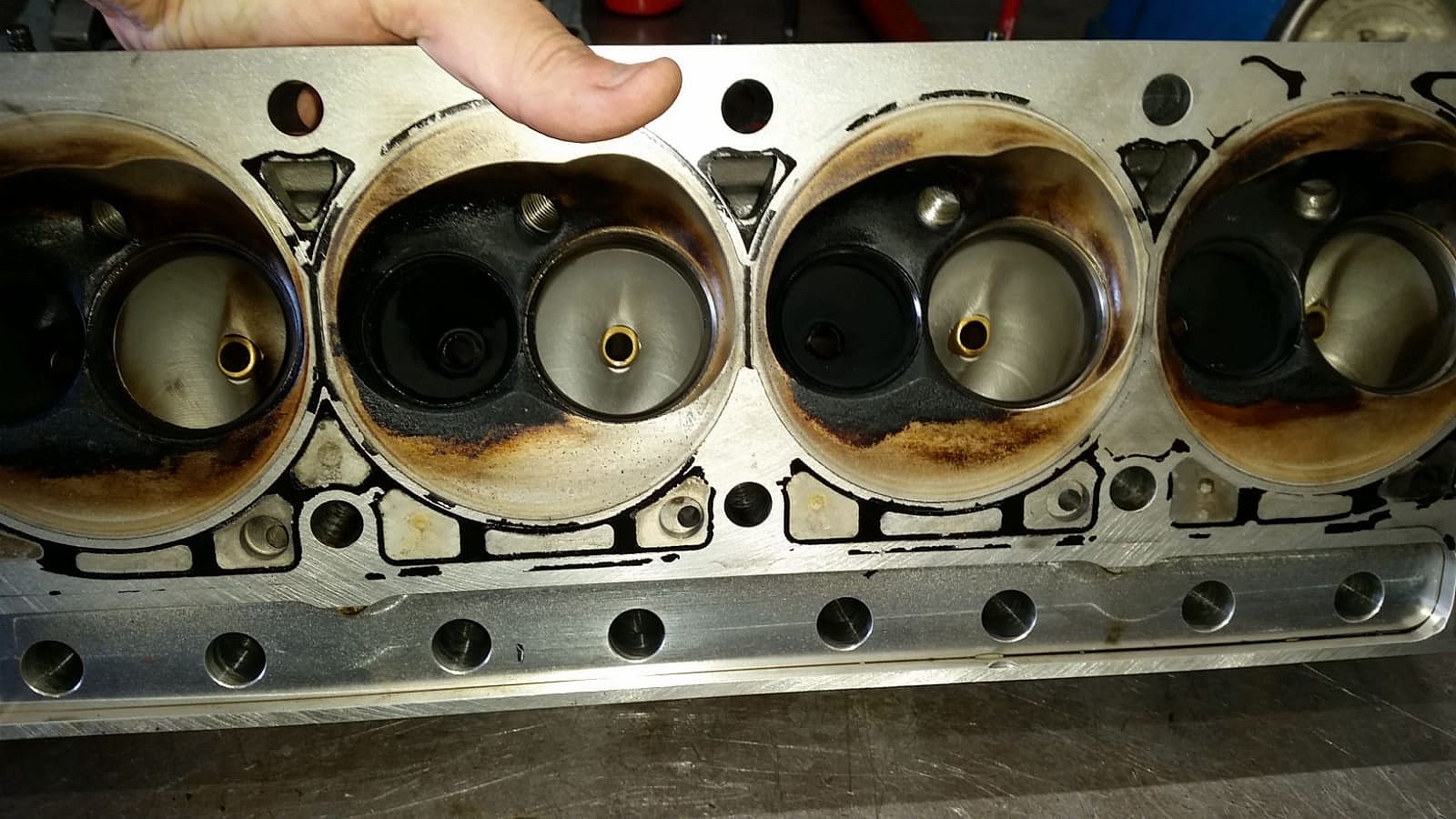

Bummer, The cratering look usually means water leak or way to little octane, that's Detonation.

Or oil getting through and lowering it.

Its interesting that it is also the intake side.

Piston is thinnest there. You can't see from the angle of the shot, but as that valve relief moves back down and to the right, it also shallows. The center of where it broke is the balance between getting close to the edge and still being deep enough. In other words, that's the closest point to the top ringland.

Note the peppering on the top flat of the piston, this thing did get run lean for a bit to cause the sand blasting or peppering look also detonation. I would pull the valves too, if you got some debris between the seat and valve it will need a valve job. Also it can transfer debris during over lap so you may have some other valves that had will need to be touched up. How is the turbine wheel? Any nicks? Might be hard to tell on the exhaust side without a full tear down and cleaning. So there was detonation, no doubt.

I see the peppering. Didn't realize that was the marker of detonation. The stuff I've seen before were pitted more deeply. You can barely feel this stuff on the surface of the piston.

Well, up through pulling the head, the motor's run very well. There has never been the slightest hint of an issue... noise, rattle, vibration, smoke.... nothing. I just dismissed the oil usage as the rings having larger gaps since it's a high-boost car and figured that was my oil consumption issue. In fact, I wasn't even really looking for it. Just thought my buddies bore scope was cool and wanted to try it out. I'm just surprised that something like this would have no more noticeable a symptom than high oil consumption.

The rest of the pistons look good. Now that I'm looking for it though, I do see even slighter peppering at the top of #4.

I have no plans for a full tear down. I didn't even have to pull any accessories to get this head off. I had it off in about 3 hours, taking my time. In fact, because I'm moving in 3 months, I'm probably just going to slap it back together for now until I can get settled back at Fort Knox and find a nice machine shop that can help me out. I won't be racing or pushing it anymore, but it runs/drives perfectly fine, and as it has done so for almost 2 years, I'm not afraid of running it so I can move it around under its own power.

As you advise, I'll get the head checked out professionally. I might do that now, since it's already apart. To the naked eye, it looks alright.

Last edited: