I was going to shoot a video of my fender repair. I scrapped that idea because the kids wouldn't stop running through the garage.

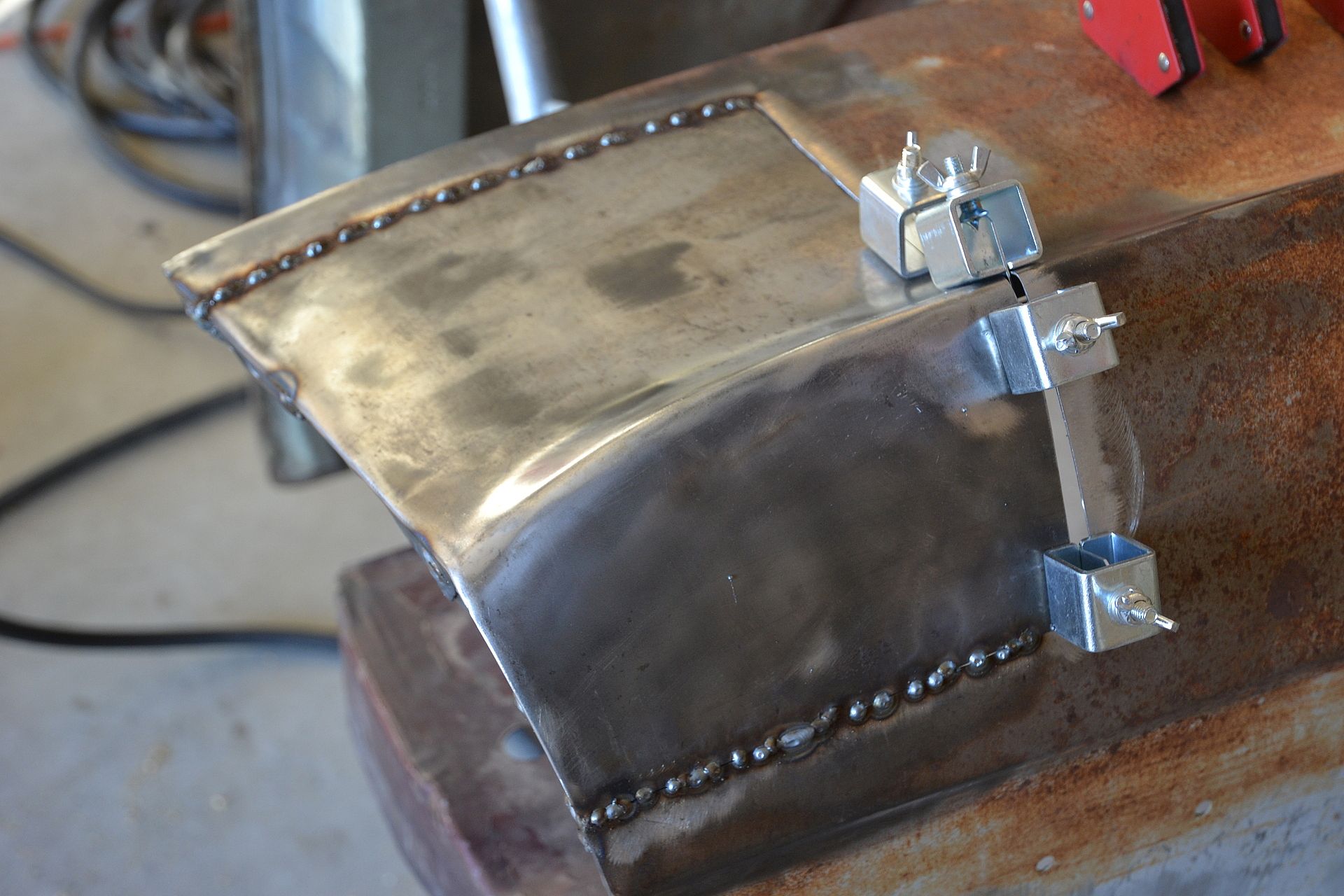

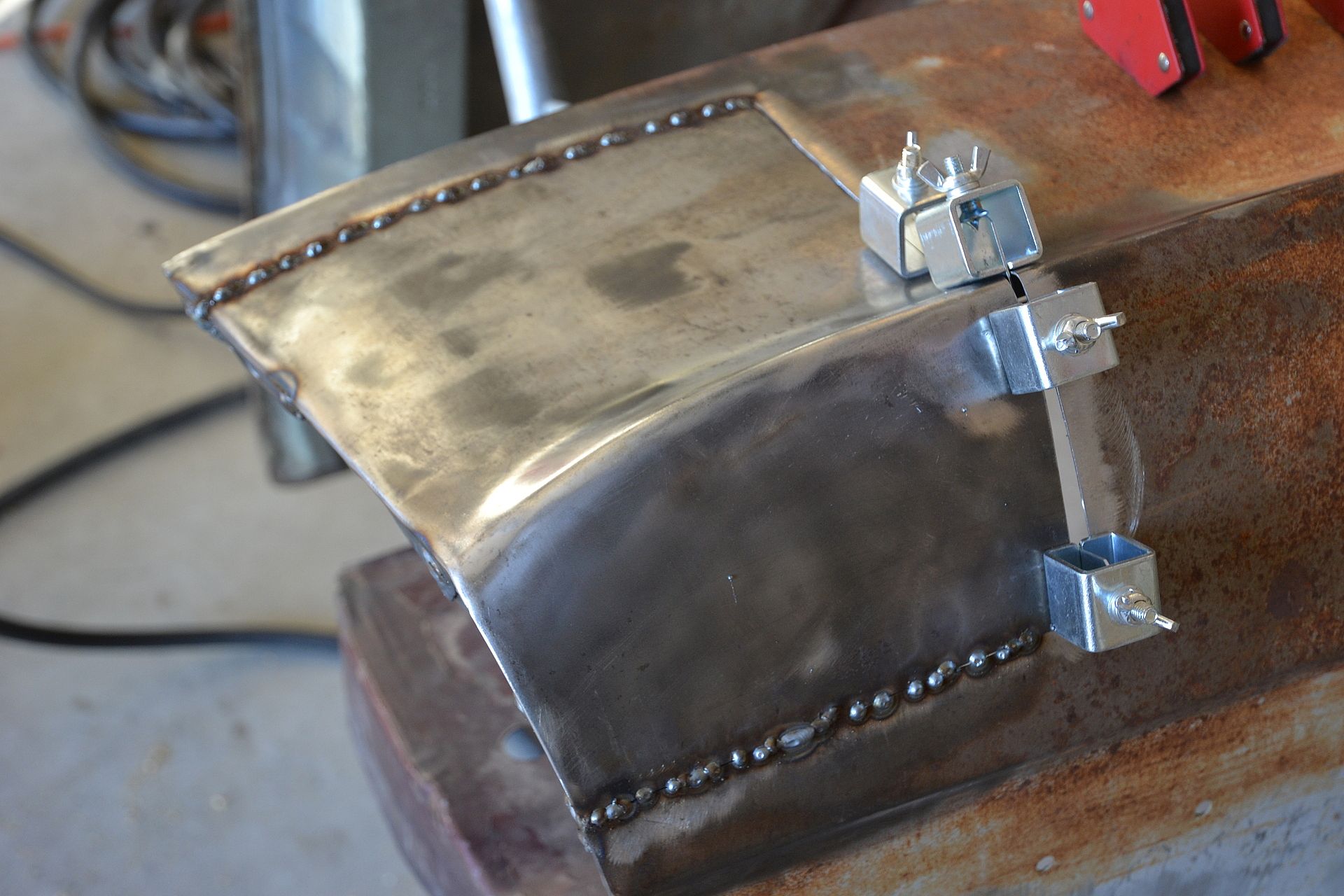

Got the headlight bucket where it needed to be and welded that in. Then started on the graft.

I still have some welding to do. I'll pick it back up tomorrow. I'm also going to need to make a small filler piece because, of course, I cut one side just a tad short. I think this may actually turn out pretty good.

Got the headlight bucket where it needed to be and welded that in. Then started on the graft.

I still have some welding to do. I'll pick it back up tomorrow. I'm also going to need to make a small filler piece because, of course, I cut one side just a tad short. I think this may actually turn out pretty good.