You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Progress Thread The "grátis" 1966 Coupe - final sheet metal repairs

- Thread starter 02 281 GT

- Start date

-

Sponsors (?)

horse sence

15 Year Member

@horse sence if I recall correctly, the two smaller holes on either side here were from two sheet metal screws whose only purpose was the hold the pedal support in place on the assembly line until the master cylinder was installed, right?

I just want to make sure before I go ahead and weld those holes up.

I just want to make sure before I go ahead and weld those holes up.

I haven't been able to motivate myself to work on the car until today.

First off, it took a while for me to figure out that having the valve at the bottom of the tank wide open was letting too much of the glass beads get by. It took a while before I figured that out.

Once I did things went more smoothly. I managed to get the inside of the dash blasted and painted. This stuff gets everywhere. Fortunately, I managed to sweep up quite a bit.

I wasn't trying to make it look good. My main concern is rust prevention.

I got most of the lower cowl blasted but didn't manage to finish before I ran out. I hadn't yet bought a sieve and bucket, so I wasn't able to start again. I'll take care of that tomorrow and maybe finish blasting the lower cowl tomorrow.

Once I ran out of blast media I decided to cut out the rusted section on the driver's side and fabricate something to replace it. I'll weld it in tomorrow or next week.

There is still a bunch of glass inside the car that I'll vacuum up and recover. I think I should be able to reclaim enough to finish blasting the cowl at which point I'll paint it and weld it back on. I'm not going to try to get the fender aprons or tail panel put back together before we move. I figure I'll be fine to move the car as long as I get the cowl reinstalled before moving day.

First off, it took a while for me to figure out that having the valve at the bottom of the tank wide open was letting too much of the glass beads get by. It took a while before I figured that out.

Once I did things went more smoothly. I managed to get the inside of the dash blasted and painted. This stuff gets everywhere. Fortunately, I managed to sweep up quite a bit.

I wasn't trying to make it look good. My main concern is rust prevention.

I got most of the lower cowl blasted but didn't manage to finish before I ran out. I hadn't yet bought a sieve and bucket, so I wasn't able to start again. I'll take care of that tomorrow and maybe finish blasting the lower cowl tomorrow.

Once I ran out of blast media I decided to cut out the rusted section on the driver's side and fabricate something to replace it. I'll weld it in tomorrow or next week.

There is still a bunch of glass inside the car that I'll vacuum up and recover. I think I should be able to reclaim enough to finish blasting the cowl at which point I'll paint it and weld it back on. I'm not going to try to get the fender aprons or tail panel put back together before we move. I figure I'll be fine to move the car as long as I get the cowl reinstalled before moving day.

horse sence

15 Year Member

The two small holes hold the bracket for the brake pedal to the fire wall ,dont weld them up@horse sence if I recall correctly, the two smaller holes on either side here were from two sheet metal screws whose only purpose was the hold the pedal support in place on the assembly line until the master cylinder was installed, right?

I just want to make sure before I go ahead and weld those holes up.

I just screened my enough to get big stuff out to keep it from clogging up the blaster. The media gets contaminated, but I used my glass beads over and over when I blasted my car.

I feel you pain on the stuff getting in every space imaginable!

I feel you pain on the stuff getting in every space imaginable!

That’s what I was thinking. There at least isn’t anything big enough left in it that will clog the blaster. I really just need to get the cowl finished so I can get it reinstalled.I just screened my enough to get big stuff out to keep it from clogging up the blaster. The media gets contaminated, but I used my glass beads over and over when I blasted my car.

I feel you pain on the stuff getting in every space imaginable!

Thanks!

Fwiw-when I was at my old job,we reused our blasting glass over and over,and only strained it through a grate on top of our pot. Like mentioned above, just to catch the big stuff

So I went ahead and pressed on with fixing the rusted area on the driver's side kick panel. Good as new.

I got back to blasting and got the majority of the scale and rust removed from the lower cowl. All I need now is to repair the rusted areas in the lower cowl, rust proof, and then it's ready to be reinstalled. I ordered some seam sealer for the occasion that should get here early next week.

I got back to blasting and got the majority of the scale and rust removed from the lower cowl. All I need now is to repair the rusted areas in the lower cowl, rust proof, and then it's ready to be reinstalled. I ordered some seam sealer for the occasion that should get here early next week.

I'm getting better at the patch work. I really need to get better by the time I start getting to exterior panels that people will actually see.the little metal patch looks good and the home blasting looks to be kickin rusts ass!

It was far too cold to work on the car outside today. I decided to just cover everything up for now.

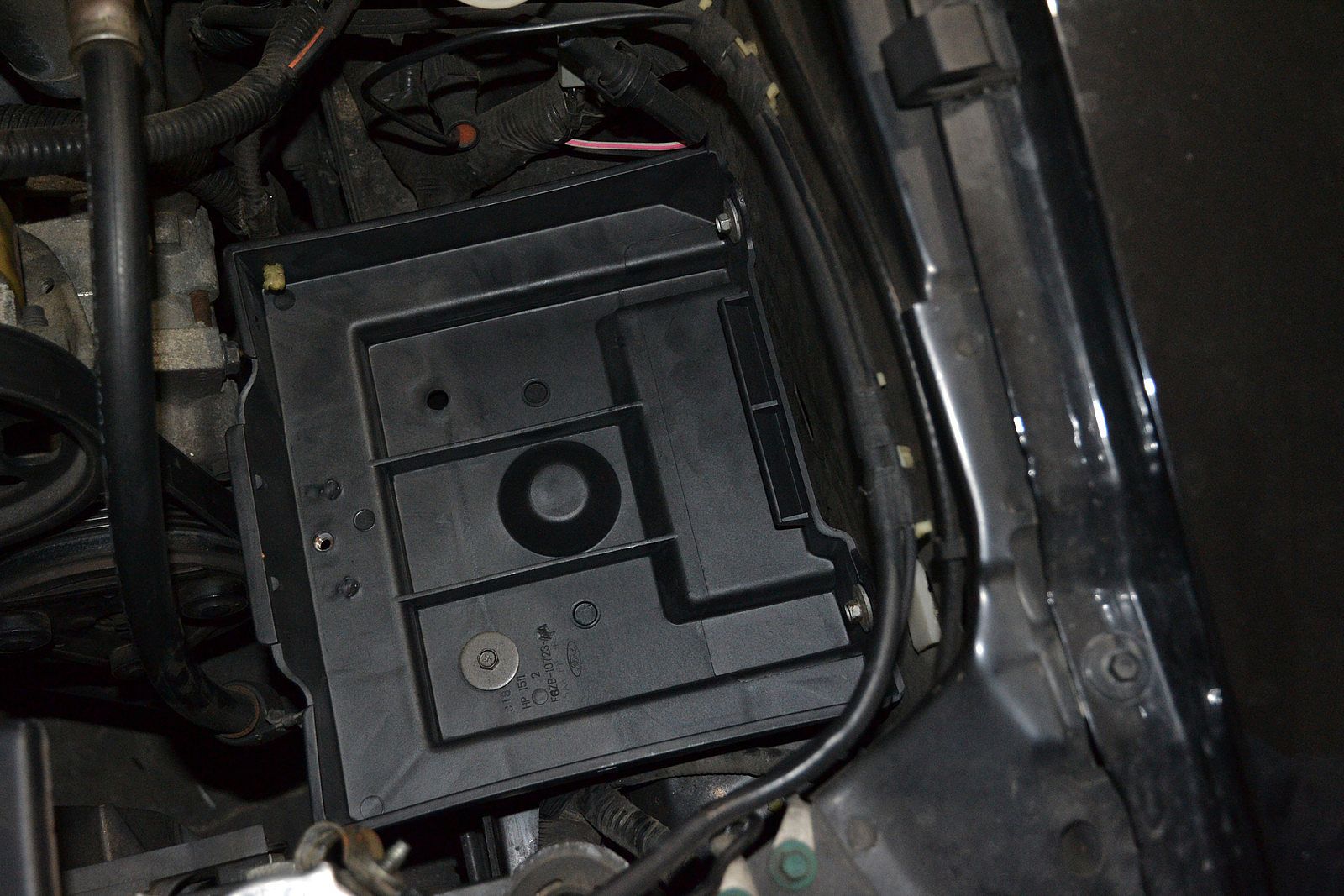

I did manage to get some small work done on my '95 Cobra. I busted the original battery tray when I jumped on the Optima bandwagon in 2012. Said red top gave up the ghost this past weekend (not a bad run) and I decided now was a great time to replace my broken battery tray. Fortunately, the SN-95 battery trays are still easy to come by for cheap. Brand new Ford part for less than $20. I had to replace the bolt that goes into the frame rail. That discontinued bolt wasn't as inexpensive.

More work on the lower cowl today. There was still a little bit of old seam sealer on the lower cowl I wire wheeled off. I then removed the old vent hats and cleaned up the metal beneath. All I need is to get some 20 gauge sheet metal to build some new vent hats. I'll try to document how I put them all together.

Sure would be nice to have a metal brake.

There's also a small bit of rusted area to patch in the lower. This is in the same spot where the kick panel rust was.

Sure would be nice to have a metal brake.

There's also a small bit of rusted area to patch in the lower. This is in the same spot where the kick panel rust was.

I completed the repairs to the lower cowl today.

I used a thicker piece of steel as a straight edge to help ensure the strips I cut were of uniform width. I then used a lot of clamps and one of the old vents as a form to make the needed circle. The strips I had weren't long enough to make a complete circle on their own. I ended up cutting two pieces from the old vents that weren't rusted to bridge the gap. That worked pretty well.

The new vents just sitting on the cowl waiting for welding.

Old hat, as they say.

I welded along the inside perimeter of the vents. I didn't do much blending of the welds. This area will be stuffed with A LOT of seam sealer inside and out. I'll take care of that along with painting the top side of the lower cowl once I get it welded back on.

I also managed to patch the area that was swiss cheesed on the driver's side.

One more wire wheeling before applying some primer.

Seam sealer applied to the nut plates that will be exposed to weather.

And finally, some good ol' Rustoleum satin black on the bottom side. I'll primer, seam seal, and paint the top side and around the new vents once it's installed.

I used a thicker piece of steel as a straight edge to help ensure the strips I cut were of uniform width. I then used a lot of clamps and one of the old vents as a form to make the needed circle. The strips I had weren't long enough to make a complete circle on their own. I ended up cutting two pieces from the old vents that weren't rusted to bridge the gap. That worked pretty well.

The new vents just sitting on the cowl waiting for welding.

Old hat, as they say.

I welded along the inside perimeter of the vents. I didn't do much blending of the welds. This area will be stuffed with A LOT of seam sealer inside and out. I'll take care of that along with painting the top side of the lower cowl once I get it welded back on.

I also managed to patch the area that was swiss cheesed on the driver's side.

One more wire wheeling before applying some primer.

Seam sealer applied to the nut plates that will be exposed to weather.

And finally, some good ol' Rustoleum satin black on the bottom side. I'll primer, seam seal, and paint the top side and around the new vents once it's installed.

horse sence

15 Year Member

wicked93gs

15 Year Member

I feel your pain...I finished my cowl not too long ago...although I chose to just buy and slightly trim a new repop lower 67 cowl....pretty easy to fit in a 66...had to enlarge the wiper holes, file a keyway into them, and trim the front edge just very slightly...I really didn't want any risk of leaks once it was back together, which is why I decided against patching the existing one.

I went ahead and primered, seam sealed, and painted the top of the lower cowl today. It ended up being too late in the afternoon to weld, so I decided to finish stripping the layers of old paint and seam sealer/tar from the upper cowl. I also applied another coat of Rustoleum satin black to the bottom side of the upper cowl.

One last wire wheeling as with the bottom side.

Primer, liberal amounts of seam sealer, another coat of primer, and then two coats of Rustoleum.

The paint left on the upper cowl put up a good fight. Original paint plus some ugly blue metallic and yellow primer layered on top. Also removed rust and scale that had developed in the areas near the old spot welds.

And I went ahead and brought everything inside to dry overnight out of the elements. I'll weld everything (or at least the lower) on tomorrow.

I'm so glad to finally have this part complete. It's taken me way to long to get here.

One last wire wheeling as with the bottom side.

Primer, liberal amounts of seam sealer, another coat of primer, and then two coats of Rustoleum.

The paint left on the upper cowl put up a good fight. Original paint plus some ugly blue metallic and yellow primer layered on top. Also removed rust and scale that had developed in the areas near the old spot welds.

And I went ahead and brought everything inside to dry overnight out of the elements. I'll weld everything (or at least the lower) on tomorrow.

I'm so glad to finally have this part complete. It's taken me way to long to get here.

Similar threads

What's it Worth?

1970 coupe worth?

- Replies

- 3

- Views

- 669

- Replies

- 4

- Views

- 344

- Replies

- 8

- Views

- 1K

What's it Worth?

1990 Notchback 5.0

- Replies

- 4

- Views

- 374