Uh... Yeah! LOL Thanks for the lead on the oiling funnel. Going by the name it sounds like something that should be fully functional.Wow, that spring is terrible.

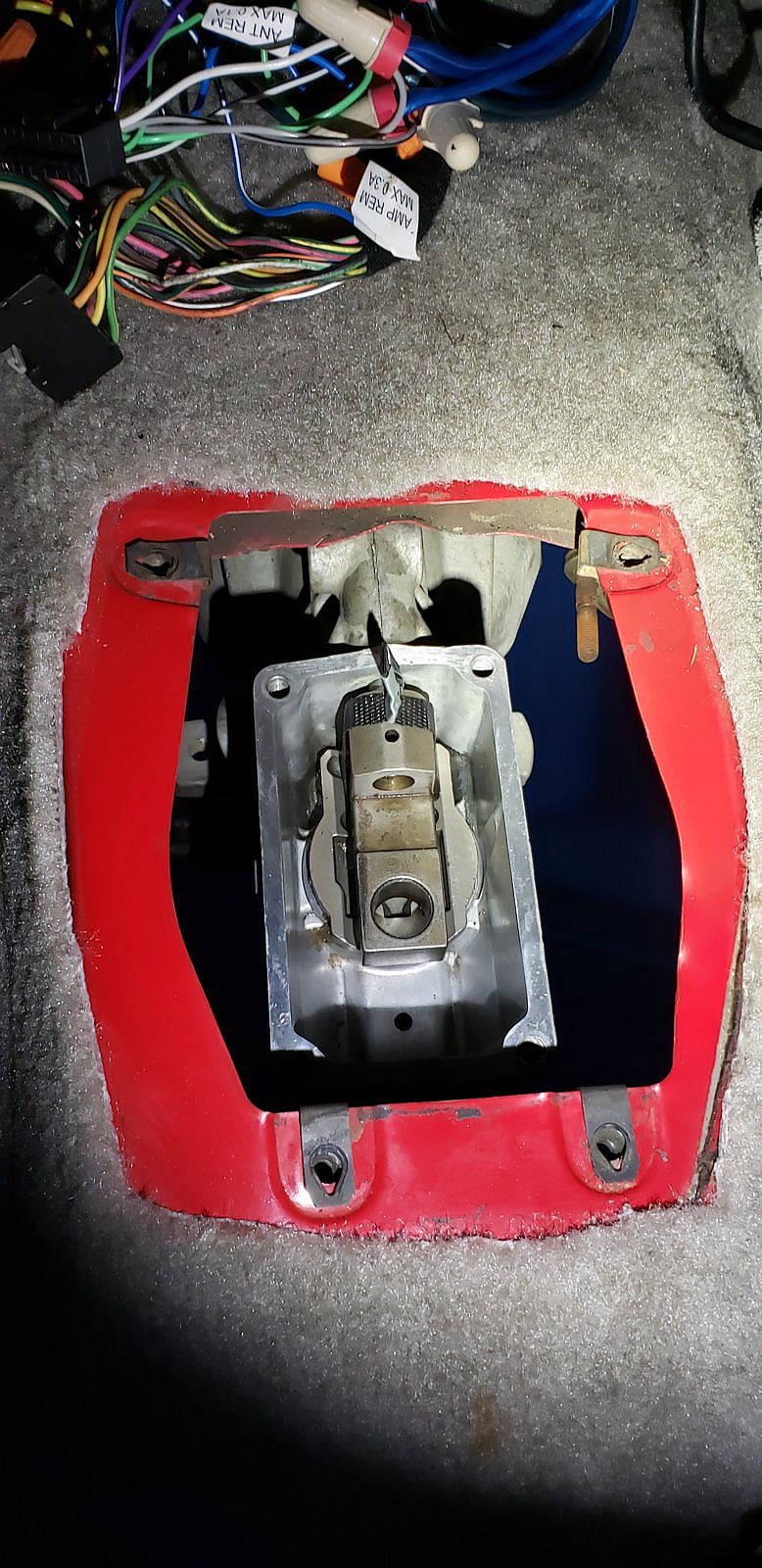

I've been trying to think of a good way of reinstalling the shifter detent spring and ball. I'm pretty much working on the car solo and as I'm sure you guys know this has to be installed as the tail shaft housing goes on, at least I think it does, but I can only be in the car or under the car at any given time. I was thinking about trying to use a heavy rubber band to hold it in place while I install the housing. Then when I get up in the car I can position the shuttle then just cut the rubber band and pull it out.

Thoughts?

I'm also going to do some youtube research as well.