Progress Thread 12th Owner: My '93 Notchback Restoration & Performance Build

- By Habu135

- 1979 - 1995 (Fox, SN95.0, & 2.3L) -General/Talk-

- 800 Replies

Mounted the oil catch can. Text drive complete and no more spewing oil.

Decided to go with the larger 12 AN fitting equipped Catch Can as I figured the larger fitting would aid in greater breathing. The limiting factor though is really the rubber tubing running from the PCV port to the catch can.

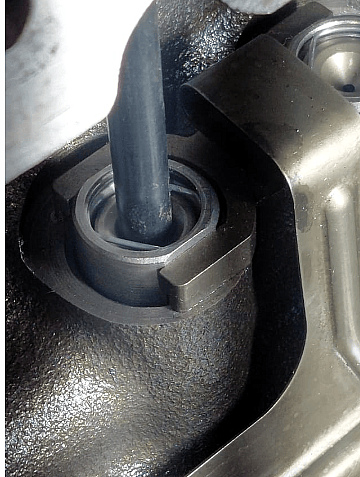

So, in the rear (traditional PCV) port area I added the missing screen, the rubber grommet, a 1/2" to 3/8" brass fitting spray painted black to blend in and then tubing to the catch can. On the passenger's side valve cover I did the same 1/2" to 3/8" brass fitting, rubber grommet to tubing to the other side of oil catch can. 14 AN fittings complete the securing of the rubber tubing and had to be purchased separately as the catch can did not come with them.

The problem I ran into was that I had to utilize a socket to screw in the brass fitting as it was so tight against the rubber grommet and PCV port(s).

I also used Rock Auto to purchase the screen as everywhere else was outrageously expensive. The Moroso Catch Can was purchased from Summit, and the brass fittings from my local hardware store.

Decided to go with the larger 12 AN fitting equipped Catch Can as I figured the larger fitting would aid in greater breathing. The limiting factor though is really the rubber tubing running from the PCV port to the catch can.

So, in the rear (traditional PCV) port area I added the missing screen, the rubber grommet, a 1/2" to 3/8" brass fitting spray painted black to blend in and then tubing to the catch can. On the passenger's side valve cover I did the same 1/2" to 3/8" brass fitting, rubber grommet to tubing to the other side of oil catch can. 14 AN fittings complete the securing of the rubber tubing and had to be purchased separately as the catch can did not come with them.

The problem I ran into was that I had to utilize a socket to screw in the brass fitting as it was so tight against the rubber grommet and PCV port(s).

I also used Rock Auto to purchase the screen as everywhere else was outrageously expensive. The Moroso Catch Can was purchased from Summit, and the brass fittings from my local hardware store.