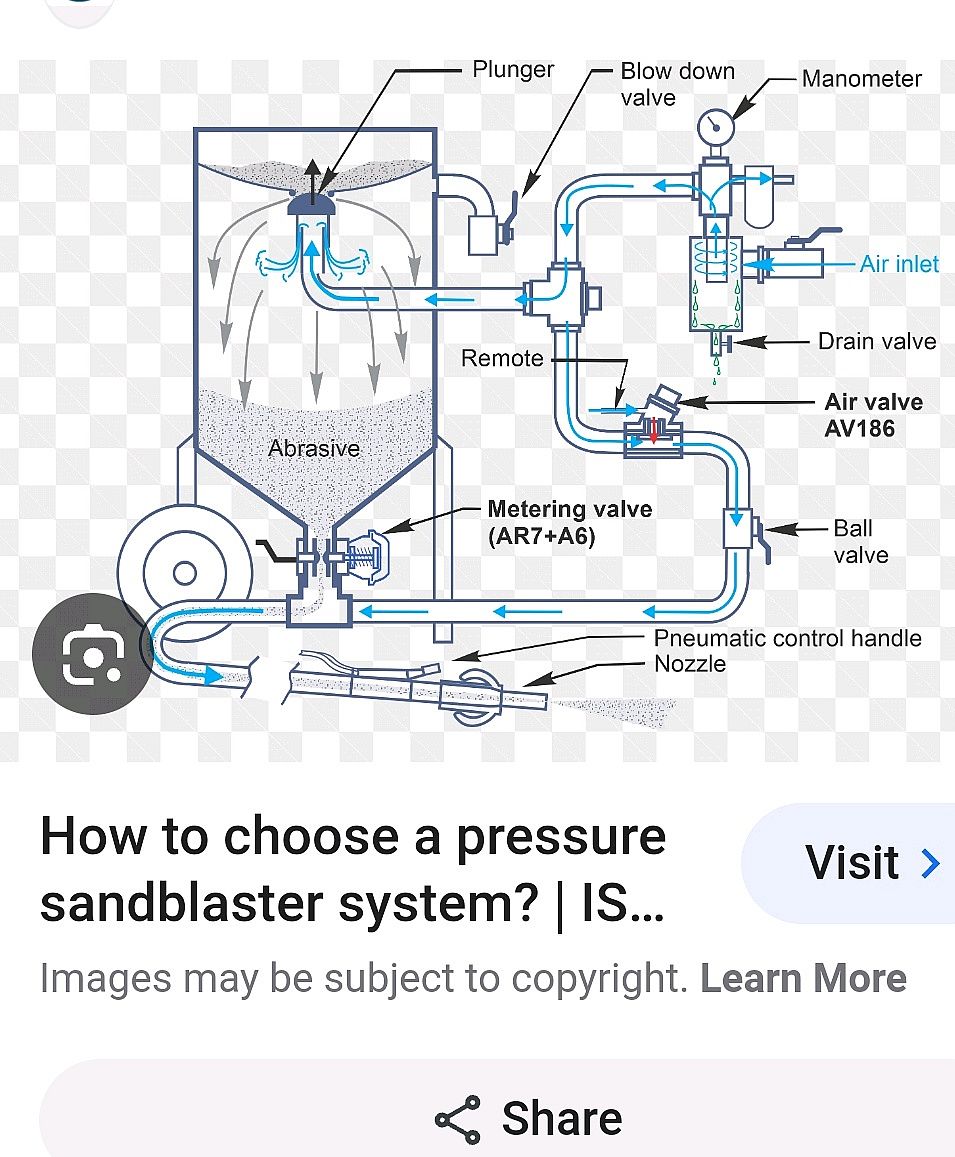

ADDED: 3-7-24. After disassembly of your rusty antique Mustang, sandblasting/mediablasting is one of the first things that needs to be done to be done.

Jim, Thanks for your reply back. I started this thread so that I wouldn't be stepping on Jim's thread "A new fb conversion for bbettto". It will be some time before I can get to this project. We have a '65 and a '66 coupe at my work that we are in the middle of, and I have a '54 F100 project going too. Current pictures of the '65 Silver blue coupe resto and the '69 Sportsroof that we are only doing the interior and a couple of underhood things too.

Ala-Tenn Mustang on Facebook

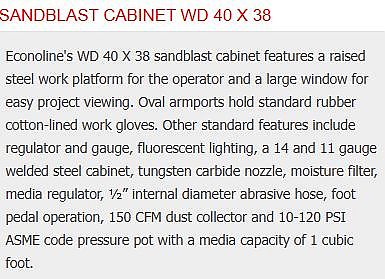

I'm trying to work out the logistics of getting some big bags of sand from near the "Gulf of Mexico". 2000 pounds each. We have been straining dry arena sand, 50 lb bags. They are easier to move than the old 100 pounders that the monument blasting company used to sell then suddenly stopped. A consistent supply of sand has always been an issue.

Picture below of a Metuchen '65 fastback that spent the first 2 decades of its life in the salty north east US. Last century it was totaled when a fairly new Jetta ran a stop sign and collided with it then the car behind the fastback ran into it semi sideways. The bondo crumbled and the weak rusty areas folded up.

It has seen its better days but it will rise again. 1965 T code fastback, poppy red with black standard interior.

Jim, Thanks for your reply back. I started this thread so that I wouldn't be stepping on Jim's thread "A new fb conversion for bbettto". It will be some time before I can get to this project. We have a '65 and a '66 coupe at my work that we are in the middle of, and I have a '54 F100 project going too. Current pictures of the '65 Silver blue coupe resto and the '69 Sportsroof that we are only doing the interior and a couple of underhood things too.

Ala-Tenn Mustang on Facebook

I'm trying to work out the logistics of getting some big bags of sand from near the "Gulf of Mexico". 2000 pounds each. We have been straining dry arena sand, 50 lb bags. They are easier to move than the old 100 pounders that the monument blasting company used to sell then suddenly stopped. A consistent supply of sand has always been an issue.

Picture below of a Metuchen '65 fastback that spent the first 2 decades of its life in the salty north east US. Last century it was totaled when a fairly new Jetta ran a stop sign and collided with it then the car behind the fastback ran into it semi sideways. The bondo crumbled and the weak rusty areas folded up.

It has seen its better days but it will rise again. 1965 T code fastback, poppy red with black standard interior.

Last edited: