There's a 3 Valve with 555 Tranny 48k miles $1200 on Facebook marketplace. Not my cup o tea, but $1200 seems a screaming deal.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Build Thread 1978 Mercury Cyclone. The pig is in the pen.

- Status

- Not open for further replies.

-

Sponsors (?)

It's the leaks that bug me the most about it. There has always been a rear oil leak that drips out of the bellhousing..I think it's coming from the head gasket at the rear but I just don't know. Once I start leaning on this thing, like I did last time this engine had this intake on it that leak will become more pronounced, and it'll leave a pretty serious puddle on the floor.

I've re-sealed my engine a couple of times... the leaks come back. I wanna try one of those rear main sleeves.

Hell,..that's some of the best input I've gotten here..id be pissed if I went through all of this just to turn around, look under the car and see a puddle upon the floor.I've re-sealed my engine a couple of times... the leaks come back. I wanna try one of those rear main sleeves.

I can almost live with " that's the way it is".

Yeah, I know some guys don't have the issue. I don't recall having any leaks when my car had a mild n/a engine. I didn't have any leaks for the break-in period. I get leaks when I start hammering it. So, my theory is that when you get to a certain level of torque/power, you put enough pressure on the rear main that it will open it up and start to leak. Or, maybe I just can't do that job right... definitely also possible. It's not leaking enough to cause any mechanical concern. It just amounts to drips of oil staining the garage floor. Guess I'll have to paint it. I can live with it in the big picture.

Yeah, I know some guys don't have the issue. I don't recall having any leaks when my car had a mild n/a engine. I didn't have any leaks for the break-in period. I get leaks when I start hammering it. So, my theory is that when you get to a certain level of torque/power, you put enough pressure on the rear main that it will open it up and start to leak. Or, maybe I just can't do that job right... definitely also possible. It's not leaking enough to cause any mechanical concern. It just amounts to drips of oil staining the garage floor. Guess I'll have to paint it. I can live with it in the big picture.

I figure with everything else being equal,

More horsepower = More cylinder pressure = More opportunity for blowby

True, and I expect that larger ring gaps for boosted cars also contribute to more blow-by.

However, most aggressively boosted turbo cars, like mine, are well-vented to atmosphere to prevent crank case pressure. I have the valve covers vented through a catch can, and the PCV system is dumped.

PCV could theoretically be routed to the down pipe and use the venturi effect to provide a vacuum. That only works on cars with very free flowing exhaust, straight through style mufflers at the worst, that won't build back pressure after the turbo, though.

If this is done right, there shouldn't be enough pressure on the low end to compromise the seals.

However, most aggressively boosted turbo cars, like mine, are well-vented to atmosphere to prevent crank case pressure. I have the valve covers vented through a catch can, and the PCV system is dumped.

PCV could theoretically be routed to the down pipe and use the venturi effect to provide a vacuum. That only works on cars with very free flowing exhaust, straight through style mufflers at the worst, that won't build back pressure after the turbo, though.

If this is done right, there shouldn't be enough pressure on the low end to compromise the seals.

The second ring is the gapless ring, it uses a rail that is installed 180* out from the gap portion. Ring gaps are still what you would expect.

Gapless Rings ?

Hello, after your help to find the right damper I have one more question. What piston rings to use in a high rpm high boost motor first gapless...

First reading indicates it's not something to pursue. Old data point, though.

"-will-somebody-just-slap-me-please"

No somebody slap me.....

It leaks?

Then pull the defective Welsh plug out.

Rear Oil gallery hexagonal bolt leaks are not uncommon at all due to the intense desire for Ford to cast these engines with less iron. If you give the customer less engine, you move into the old Alfred P Sloan Jr. era of built in obsolencence. Fords main seal changes to the poly ethlene seal made matters worse. The old asbestos or ahem, expaded rock fiber rope seal was a pretty good thing if you did it right. If you do a PE main seal, media blast the crank flange, and use the ever so slightly smaller size with a 5 to 10 degree shut line mismatch. A bigger size leaks. Its a surface texture thing again.

Now your noise solution is to

1. Add the LMR K member 1/2" lowering kit. Put the engine mounts back in, same as the F150 in line six isolators. Do the mods to get the rack arm and right height and aligment right.

2. take the 200 cubic inch cast nodular iron 3.126" stroke crank I have here, and reweld the nose up from 1.248 to 1.375 for your 302 timing gear,

3. and drop in the 6.275" rods they come with.

4. Compression ratio drops, and you can then put an extra 1000 rpm on the engine, with 18 pounds of boost easy.

You expand the rev range with the abilty to run a lot more revs with no piston rocking, less compression, and more boost.

Now, the know how to fix it is this:-

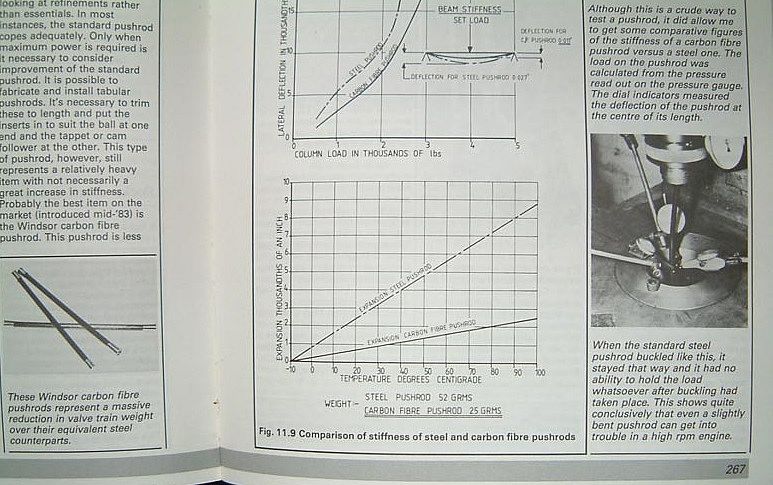

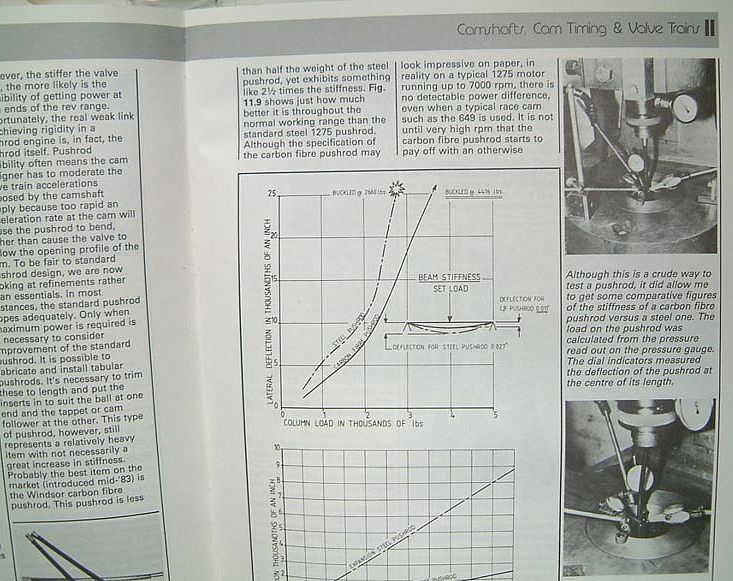

5. Get some carbon fibre aramid pushrods from either Windsor Moulding and Manufactoring Company,

or have some made up from the stock supplier in Cali. Noise gets dampened right out with a massive improvment in stiffness.

6. The main problem with the 250 in line six is the alloy Honda head transmitts vibration much more than iron.

7. Its rocker pedastools creak under the valve loads. As you'll well know, the ill idling, 1-barrel loving, Bump Stick toting, Dizzy Stabbing Big Six guys , the great nancey's of all six cylinder demigods, woefully complain about noise of any form when they do rocker gear, cam or alloy timing gear upgrades. Moan, moan, moan. Good Moaning America. And Iron is a nicer metal to posilock than alloy, lemme tell ya.

The absence of a Big Six 300/4.9 nylon fibre coated timing gear set means the double row 302 timing chain needs a tensioner to keep the chain lash down. And thrash it does on a six. The 2300 and 2500 OHV engines based on your six got a chain tensioner, and a different kind of chain pitch to quieten it down.

8. Your side plate is a noise amplifier too, and

9. solid rollers beside a steel plate wont be a silent lamb.

It wasn't the deaf and blind Helen Keller from Alab'm who set up a noise lab. In fact, Swabian Albert Keller did, and the Aussie Cortina and Thunderbird Turbo Coupe were each such vibrating hulks, they sent them to get noise and vibration mapped, and the quietened down the 2000 and 2300 OHC engines quick smart in the Fox style engine bay each had. Padding and keying in the accessory drive frequency's so they didn't amplify the noise was the secrete.

Primarily, with dense padding. Like you might find in, say, a padded cell. They tried to put me in there you know. But I had a pin...

Hope you catch the noise and leaks, CMA. Swabian thick sour stew, with fava beans...

Just try and kill THAT CMA. Go ahead. Make my day!

No somebody slap me.....

It leaks?

Then pull the defective Welsh plug out.

Rear Oil gallery hexagonal bolt leaks are not uncommon at all due to the intense desire for Ford to cast these engines with less iron. If you give the customer less engine, you move into the old Alfred P Sloan Jr. era of built in obsolencence. Fords main seal changes to the poly ethlene seal made matters worse. The old asbestos or ahem, expaded rock fiber rope seal was a pretty good thing if you did it right. If you do a PE main seal, media blast the crank flange, and use the ever so slightly smaller size with a 5 to 10 degree shut line mismatch. A bigger size leaks. Its a surface texture thing again.

Now your noise solution is to

1. Add the LMR K member 1/2" lowering kit. Put the engine mounts back in, same as the F150 in line six isolators. Do the mods to get the rack arm and right height and aligment right.

2. take the 200 cubic inch cast nodular iron 3.126" stroke crank I have here, and reweld the nose up from 1.248 to 1.375 for your 302 timing gear,

3. and drop in the 6.275" rods they come with.

4. Compression ratio drops, and you can then put an extra 1000 rpm on the engine, with 18 pounds of boost easy.

You expand the rev range with the abilty to run a lot more revs with no piston rocking, less compression, and more boost.

Now, the know how to fix it is this:-

5. Get some carbon fibre aramid pushrods from either Windsor Moulding and Manufactoring Company,

or have some made up from the stock supplier in Cali. Noise gets dampened right out with a massive improvment in stiffness.

6. The main problem with the 250 in line six is the alloy Honda head transmitts vibration much more than iron.

7. Its rocker pedastools creak under the valve loads. As you'll well know, the ill idling, 1-barrel loving, Bump Stick toting, Dizzy Stabbing Big Six guys , the great nancey's of all six cylinder demigods, woefully complain about noise of any form when they do rocker gear, cam or alloy timing gear upgrades. Moan, moan, moan. Good Moaning America. And Iron is a nicer metal to posilock than alloy, lemme tell ya.

The absence of a Big Six 300/4.9 nylon fibre coated timing gear set means the double row 302 timing chain needs a tensioner to keep the chain lash down. And thrash it does on a six. The 2300 and 2500 OHV engines based on your six got a chain tensioner, and a different kind of chain pitch to quieten it down.

8. Your side plate is a noise amplifier too, and

9. solid rollers beside a steel plate wont be a silent lamb.

It wasn't the deaf and blind Helen Keller from Alab'm who set up a noise lab. In fact, Swabian Albert Keller did, and the Aussie Cortina and Thunderbird Turbo Coupe were each such vibrating hulks, they sent them to get noise and vibration mapped, and the quietened down the 2000 and 2300 OHC engines quick smart in the Fox style engine bay each had. Padding and keying in the accessory drive frequency's so they didn't amplify the noise was the secrete.

Primarily, with dense padding. Like you might find in, say, a padded cell. They tried to put me in there you know. But I had a pin...

Hope you catch the noise and leaks, CMA. Swabian thick sour stew, with fava beans...

Just try and kill THAT CMA. Go ahead. Make my day!

Attachments

12psi with total seal gapless rings... zero blowby that I could tell.

There is no such thing as zero blowby in any IC engine. There is always some pressure escape past the rings.

True, and I expect that larger ring gaps for boosted cars also contribute to more blow-by.

Very true.

However, most aggressively boosted turbo cars, like mine, are well-vented to atmosphere to prevent crank case pressure. I have the valve covers vented through a catch can, and the PCV system is dumped.

PCV could theoretically be routed to the down pipe and use the venturi effect to provide a vacuum. That only works on cars with very free flowing exhaust, straight through style mufflers at the worst, that won't build back pressure after the turbo, though.

If this is done right, there shouldn't be enough pressure on the low end to compromise the seals.

This is why I stated "all other things being equal". Very true, you can help to reduce the amount of crankcase pressure with proper venting but you are still limited to what pressure you are able to alleviate based on the block design. SBF's were never designed to evacuate the crankcase pressures as quickly and effectively as needed with the power some of us make with them. Look at the large bay to bay breathing channels and chimneys that are cast into a coyote block to help relieve these pressures (as well as the other benefits from these provisions). You also have crankcase pressure generated by windage and the cylinder pulses contained in the crankcase that can cause pressurized leaks. I'm not saying this is the only cause, but it does contribute to the leaks we tend to see in higher horsepower/boosted SBF's.

Gapless great for the street, but max effort are a no no... to me 12psi is street level boost. Above 20 and we want a more race oriented ring package

That I could tell... means nothing showing up in my catch can unlike my last build. I completely understand the concept of crankcase pressures.There is no such thing as zero blowby in any IC engine. There is always some pressure escape past the rings.

Very true.

This is why I stated "all other things being equal". Very true, you can help to reduce the amount of crankcase pressure with proper venting but you are still limited to what pressure you are able to alleviate based on the block design. SBF's were never designed to evacuate the crankcase pressures as quickly and effectively as needed with the power some of us make with them. Look at the large bay to bay breathing channels and chimneys that are cast into a coyote block to help relieve these pressures (as well as the other benefits from these provisions). You also have crankcase pressure generated by windage and the cylinder pulses contained in the crankcase that can cause pressurized leaks. I'm not saying this is the only cause, but it does contribute to the leaks we tend to see if higher horsepower/boosted SBF's

Edit: well almost always something new to learn.

Last edited:

IIRC, the 250 pushrods for X-FLOWS are FE height at 9.625", not the 8.4375 (850-1100cc), or (1275cc) 8.75" of the little old A series.

Pushrods RichieP » Wed Oct 15, 2008 8:01 am

Has anyone thought of trying carbon fibre pushrods? I was clearing my garage out at the weekend and found a set I'd bought for a (long since scrapped) MG Metro, and got to thinking about modding them to fit my B25SS. I know in reality there's probably not much weight advantage, although they are allegedly less prone to flex at high rpm, but I do remember them being significantly quieter when running in a clattery A-series.

Thoughts/experiences?

Cheers

Richie

Attachments

Last edited:

You have to know me to know that when I get an idea, I obsess over it from the moment it pops into my head until I actually put an action plan into motion..As long as it’s in my head, every possible option to that plan is still in contention. So to clarify this right now.....

I don’t take anything lightly,...I research something until it is either do-able or not. Sometimes it don’t make no sense, but if I want it, and I can make it work.......I’m gonna make it work. Or keep at it till it does.

Does that seem like a fair self-analysis?

This engine thing for example:

The fix for my “concerns” with this engine is possible. It all boils down to noise, leaks,...and reliability.

I can have a hydraulic roller cam ground for this thing,...I can also have the front of the cam modified by the cam grinder to allow a sbf timing chain gear to fit on it ( what I’m presently using) it’ll probably cost 1000.00 to do. The lifters,....400-500 more, and I have to cut the link bar rivet off of at least one of them so that I can get them all in the holes, then on the one I removed the rivet head.......bolt and nut it back together.

Strike one against “dead reliable”.....Add a slight tightening of the sphincter muscle wondering if that nut will ever come loose/ fail/ shear.

Put at least 2000.00 into the added investment column, by the time you add gaskets back into place.

I’d imagine however that without 12 rockers hammering against the valve tips on one end, and the pushrod on the other...noise goes down measurably.

I take it a step further,.....and deal with the pistons. The place I bought these from (Racetec) quoted me 600 for the six pistons.

Add 200 for the rings, another 200 for the bearings, add 200 for the gaskets, add 750 for the machine work....another 2k

So,..that leaves the leaks then. I’m thinking it’s a plug at at the back of the motor, the rear main, or it’s getting past the cover plate,...all augmented by positive crankcase pressure....but I just put the equivalent of a 2.25” hole in the engine to let trapped crankcase pressure out of the engine by adding (3) -12 hoses to the top and bottom of the engine...maybe...they’ll cool the hell out. All in all though..I’m guessing 4K to try and make this engine quiet the phuck down...

Or I just suck it up...embrace the noise, periodically check my oil filter,..hope for the best, and let this noisy bitch eat.

The Teksid 4.6 is big money if I do it “ Mike’s way”

500 to buy it, 2200 for a rotating assy, 2000 in the heads to bring them up to spec with new cams, machine work, new k member, hydro boost, new intake, new injectors, new tb, new oil pump, headers, turbos, waste gates,.....AHHHHHHHHHHH!!!!!!!!

I can’t stand it.

It’s the look I want,....but the price will eclipse 8k by the time it’s all said and done. Probably much more.

I’ve looked at the ugly Coyote..there’s a reason they put that big assed plastic cover over that engine...without that cover it looks like ass...under that cover,...it’s......it’s.........” Yeah,...so what?”

But you can’t argue with the power..or the fact that I can buy 365 hp, and 385 ft lbs of torque out of an f150 with only 45k miles on it WITH an attached 6R 80 for 6k.. I still gotta buy the k member, I still gotta buy the hydro boost, I still gotta figure out all of the accessories.

Then there’s the Barra...I’d adapt the Barra to my 4r70. Use or modify my k member, use my brake system, use the monsters turbo and gate....but now the one I had found is gone....

I don’t take anything lightly,...I research something until it is either do-able or not. Sometimes it don’t make no sense, but if I want it, and I can make it work.......I’m gonna make it work. Or keep at it till it does.

Does that seem like a fair self-analysis?

This engine thing for example:

The fix for my “concerns” with this engine is possible. It all boils down to noise, leaks,...and reliability.

I can have a hydraulic roller cam ground for this thing,...I can also have the front of the cam modified by the cam grinder to allow a sbf timing chain gear to fit on it ( what I’m presently using) it’ll probably cost 1000.00 to do. The lifters,....400-500 more, and I have to cut the link bar rivet off of at least one of them so that I can get them all in the holes, then on the one I removed the rivet head.......bolt and nut it back together.

Strike one against “dead reliable”.....Add a slight tightening of the sphincter muscle wondering if that nut will ever come loose/ fail/ shear.

Put at least 2000.00 into the added investment column, by the time you add gaskets back into place.

I’d imagine however that without 12 rockers hammering against the valve tips on one end, and the pushrod on the other...noise goes down measurably.

I take it a step further,.....and deal with the pistons. The place I bought these from (Racetec) quoted me 600 for the six pistons.

Add 200 for the rings, another 200 for the bearings, add 200 for the gaskets, add 750 for the machine work....another 2k

So,..that leaves the leaks then. I’m thinking it’s a plug at at the back of the motor, the rear main, or it’s getting past the cover plate,...all augmented by positive crankcase pressure....but I just put the equivalent of a 2.25” hole in the engine to let trapped crankcase pressure out of the engine by adding (3) -12 hoses to the top and bottom of the engine...maybe...they’ll cool the hell out. All in all though..I’m guessing 4K to try and make this engine quiet the phuck down...

Or I just suck it up...embrace the noise, periodically check my oil filter,..hope for the best, and let this noisy bitch eat.

The Teksid 4.6 is big money if I do it “ Mike’s way”

500 to buy it, 2200 for a rotating assy, 2000 in the heads to bring them up to spec with new cams, machine work, new k member, hydro boost, new intake, new injectors, new tb, new oil pump, headers, turbos, waste gates,.....AHHHHHHHHHHH!!!!!!!!

I can’t stand it.

It’s the look I want,....but the price will eclipse 8k by the time it’s all said and done. Probably much more.

I’ve looked at the ugly Coyote..there’s a reason they put that big assed plastic cover over that engine...without that cover it looks like ass...under that cover,...it’s......it’s.........” Yeah,...so what?”

But you can’t argue with the power..or the fact that I can buy 365 hp, and 385 ft lbs of torque out of an f150 with only 45k miles on it WITH an attached 6R 80 for 6k.. I still gotta buy the k member, I still gotta buy the hydro boost, I still gotta figure out all of the accessories.

Then there’s the Barra...I’d adapt the Barra to my 4r70. Use or modify my k member, use my brake system, use the monsters turbo and gate....but now the one I had found is gone....

Work with what you got for now.

you have not driven it yet! Give it a chance to leak, rattle like a John Deere and make that whoosh noise (or whatever noise the bov makes) right after you set a patch of asphalt on fire!

the monster is kinda like a male german shepherd, it will mark it's spot. Deal with it.

you have not driven it yet! Give it a chance to leak, rattle like a John Deere and make that whoosh noise (or whatever noise the bov makes) right after you set a patch of asphalt on fire!

the monster is kinda like a male german shepherd, it will mark it's spot. Deal with it.

Months ago I posted and said that the use of a P&G valve gapper would probably fix your sewing machine engine noise.

I had a home made version and it worked very well. It made an amazing improvement in an 1800 CC MG-B; it was like a shot of NO2 when the engine hit 3500 RPM..

You may find one on eBay or a swap meet, but even if you didn't, a home brew version isn't that difficult to make. A cheap dial indicator, some 1/4" aluminum plate and a 2"x2"x1" chunk of aluminum block are the main components.

Here's how it works:

View: https://www.youtube.com/watch?v=5NPM185P33w

I had a home made version and it worked very well. It made an amazing improvement in an 1800 CC MG-B; it was like a shot of NO2 when the engine hit 3500 RPM..

You may find one on eBay or a swap meet, but even if you didn't, a home brew version isn't that difficult to make. A cheap dial indicator, some 1/4" aluminum plate and a 2"x2"x1" chunk of aluminum block are the main components.

Here's how it works:

View: https://www.youtube.com/watch?v=5NPM185P33w

Months ago I posted and said that the use of a P&G valve gapper would probably fix your sewing machine engine noise.

I had a home made version and it worked very well. It made an amazing improvement in an 1800 CC MG-B; it was like a shot of NO2 when the engine hit 3500 RPM..

You may find one on eBay or a swap meet, but even if you didn't, a home brew version isn't that difficult to make. A cheap dial indicator, some 1/4" aluminum plate and a 2"x2"x1" chunk of aluminum block are the main components.

Here's how it works:

View: https://www.youtube.com/watch?v=5NPM185P33w

While I appreciate your input Joe, I really don't get how you think this auto-gapped tool is gonna change anything. Valve lash is valve lash. I set lash the way it's always been done by race teams and engine builders around the world. Intake set when the exhaust just begins to open, exhaust set when the intake just starts to close.

That valve gapper tool is for somebody that thinks it's some mystery to know when the valve is on the base circle of the cam.

Well, last night marked the restart. And although it popped right off when I turned the key, it died just as quickly. The throttle screw ( that I can now get to) needed opening. After several attempts, it finally idled. While I was attempting that however, the thing was idling maybe in the 400-500 rpm range,.....choking and wheezing along. The fact that it will idle so low Tells me that I've now got a sealed up intake system. As a byproduct, I've now got the dreaded tb whistle...I had it before with this combo.

First impression compared to the old ITB system is that the engine is more responsive to throttle input. Trying to keep the thing running, and having to pedal the throttle resulted in a couple of unwanted engine revs that seemed very touchy. Steve has the initial tune right now, and a short DL. He was using timing to control idle speed before as the engine warmed and you can see that happening still, but it's simply too fat. Idling at 11.9 -12 AFR when it'll happily idle at 13.9 is what I'll shoot for..

Hel,..maybe I'll be able to drive this thing this Saturday.

First impression compared to the old ITB system is that the engine is more responsive to throttle input. Trying to keep the thing running, and having to pedal the throttle resulted in a couple of unwanted engine revs that seemed very touchy. Steve has the initial tune right now, and a short DL. He was using timing to control idle speed before as the engine warmed and you can see that happening still, but it's simply too fat. Idling at 11.9 -12 AFR when it'll happily idle at 13.9 is what I'll shoot for..

Hel,..maybe I'll be able to drive this thing this Saturday.

- Status

- Not open for further replies.