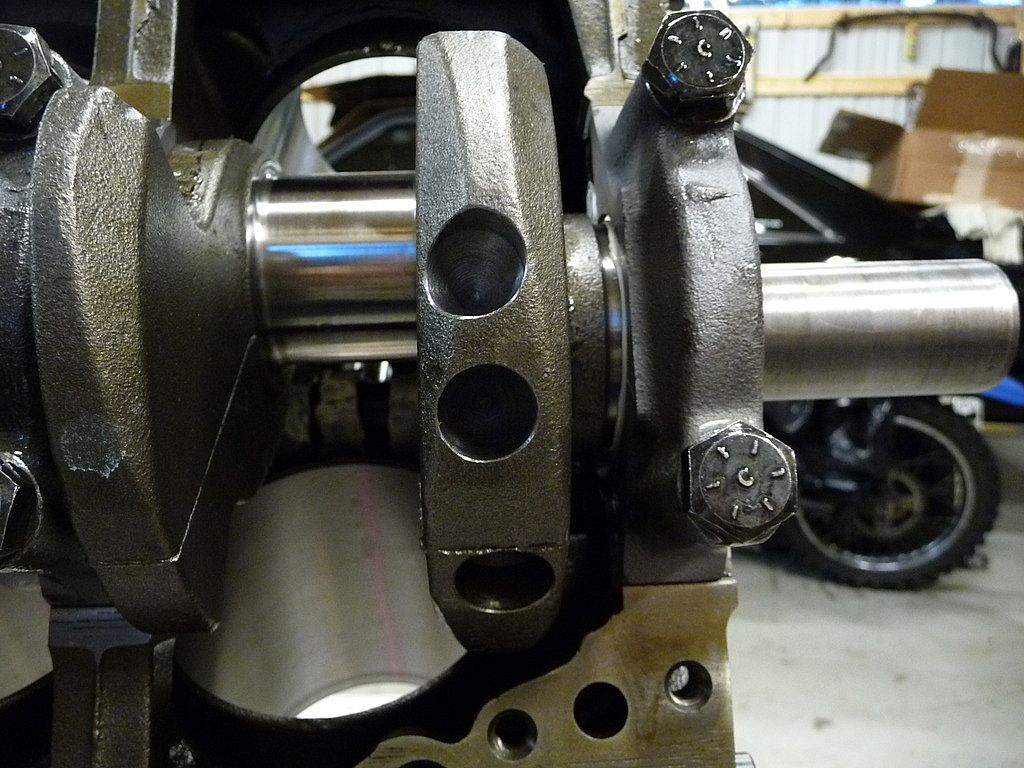

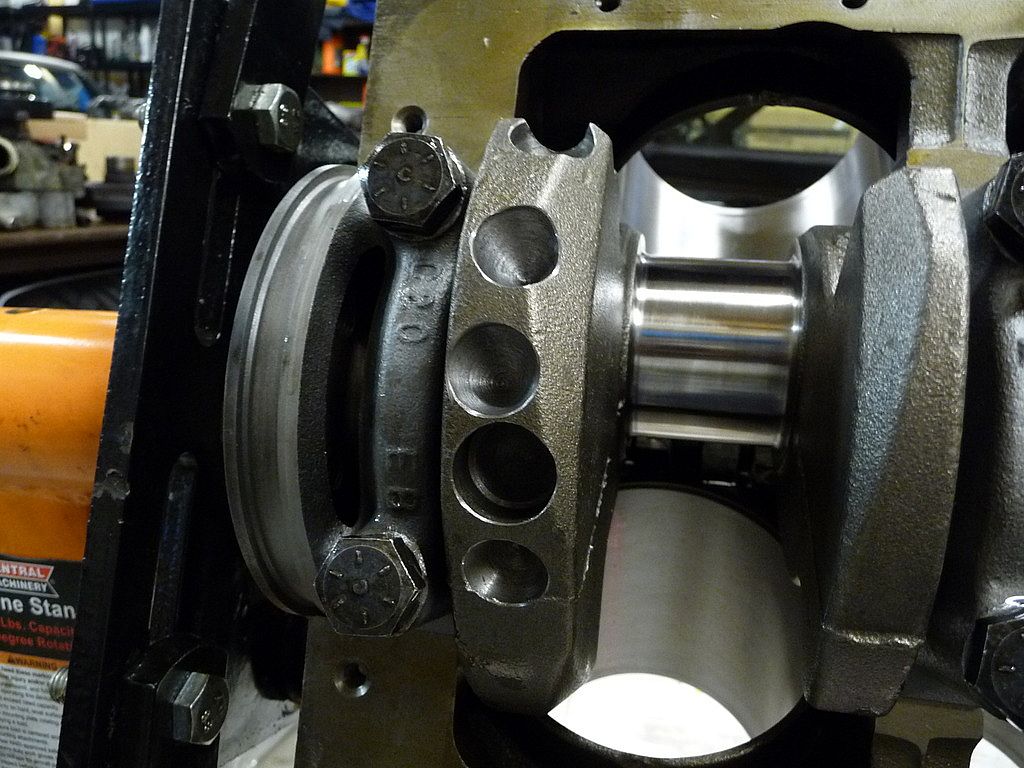

Balanced crank

Machinist stamped crank

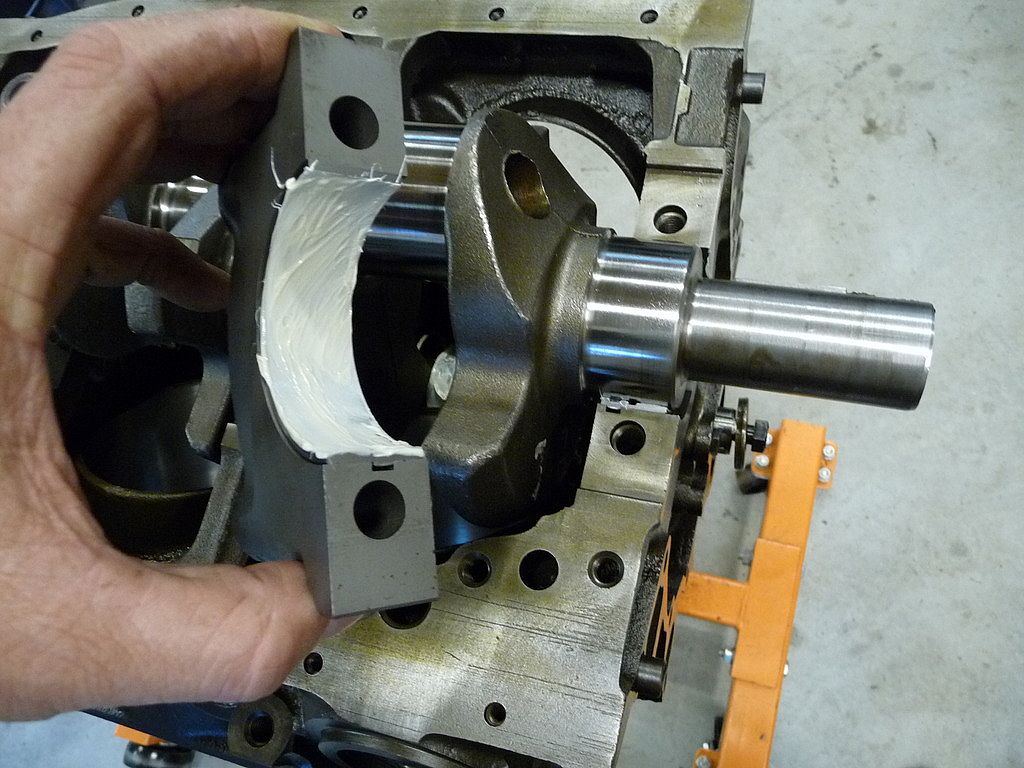

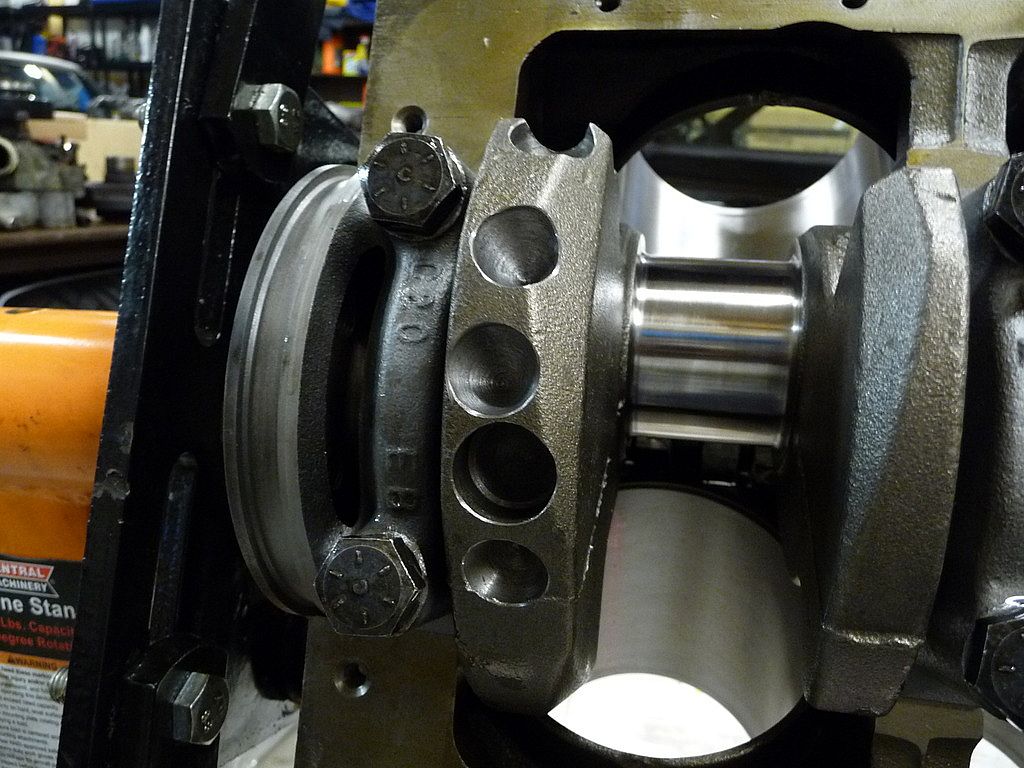

Main bearing clearances

Moly assembly lube

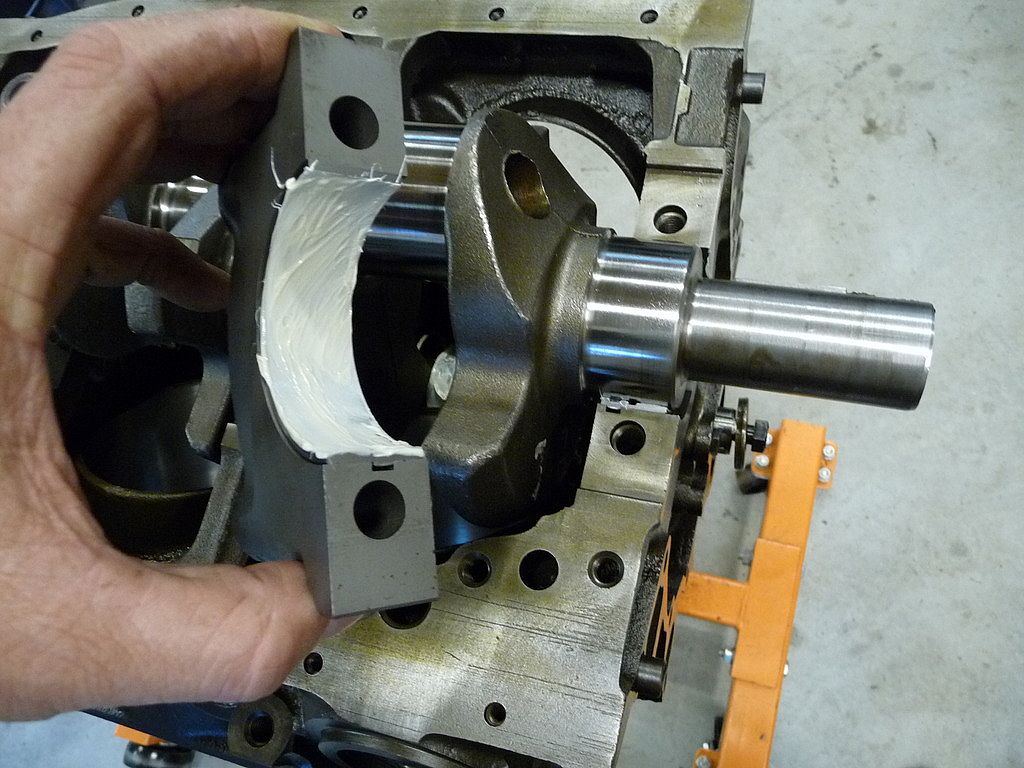

Rear main in

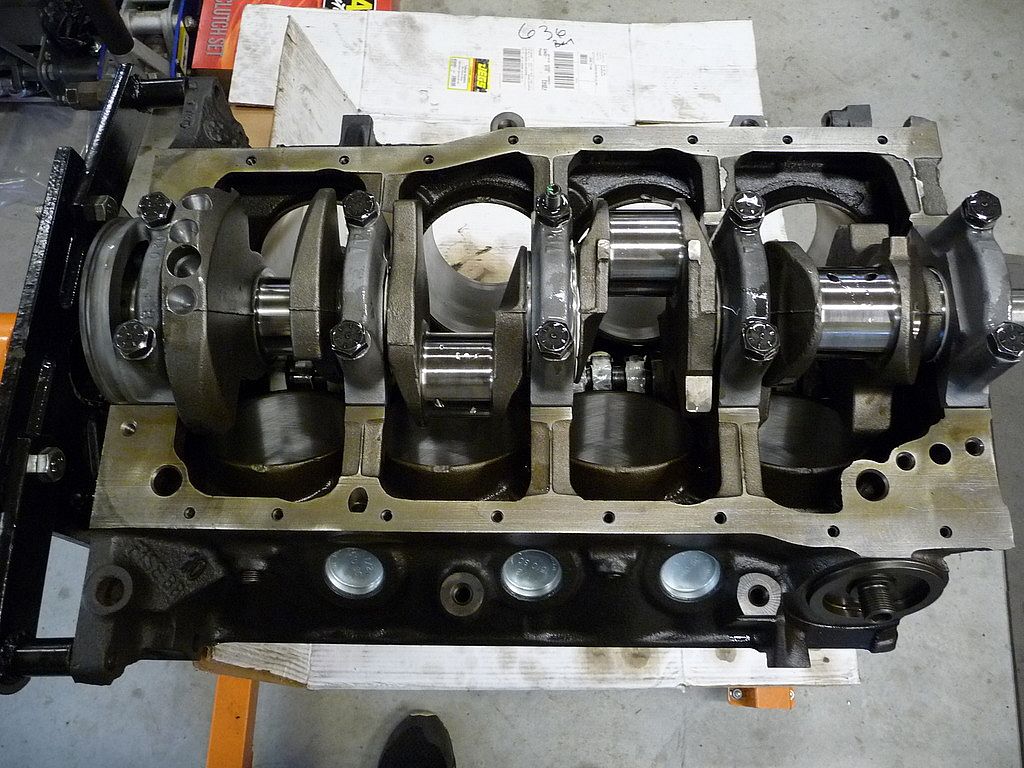

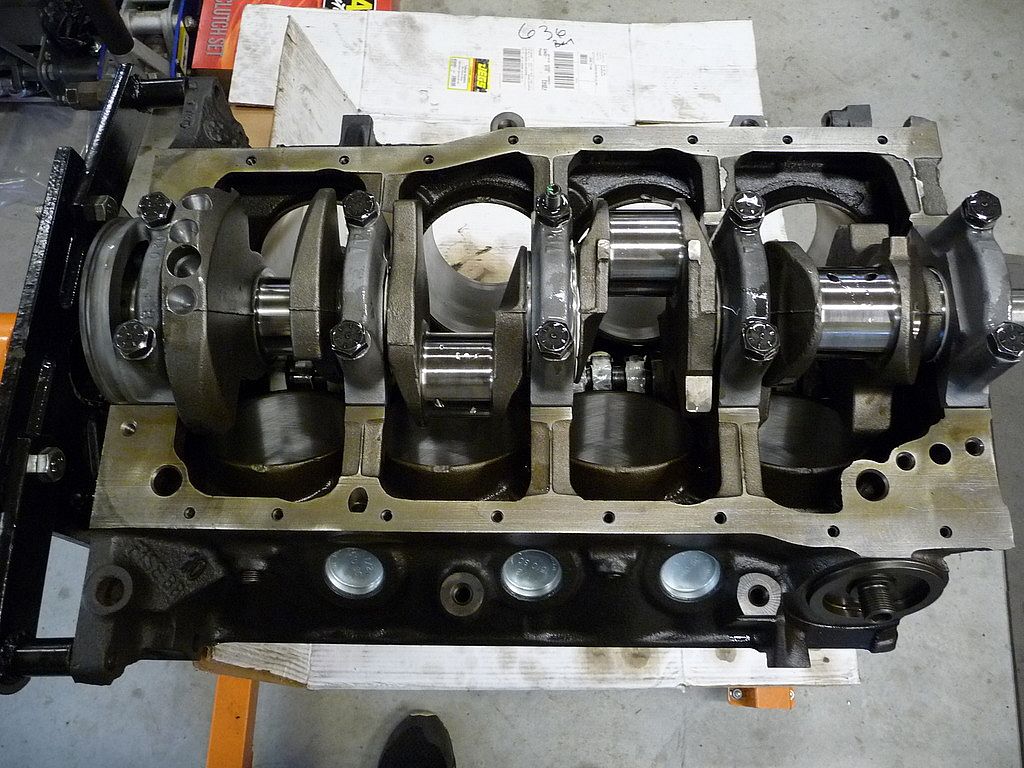

Crank installed

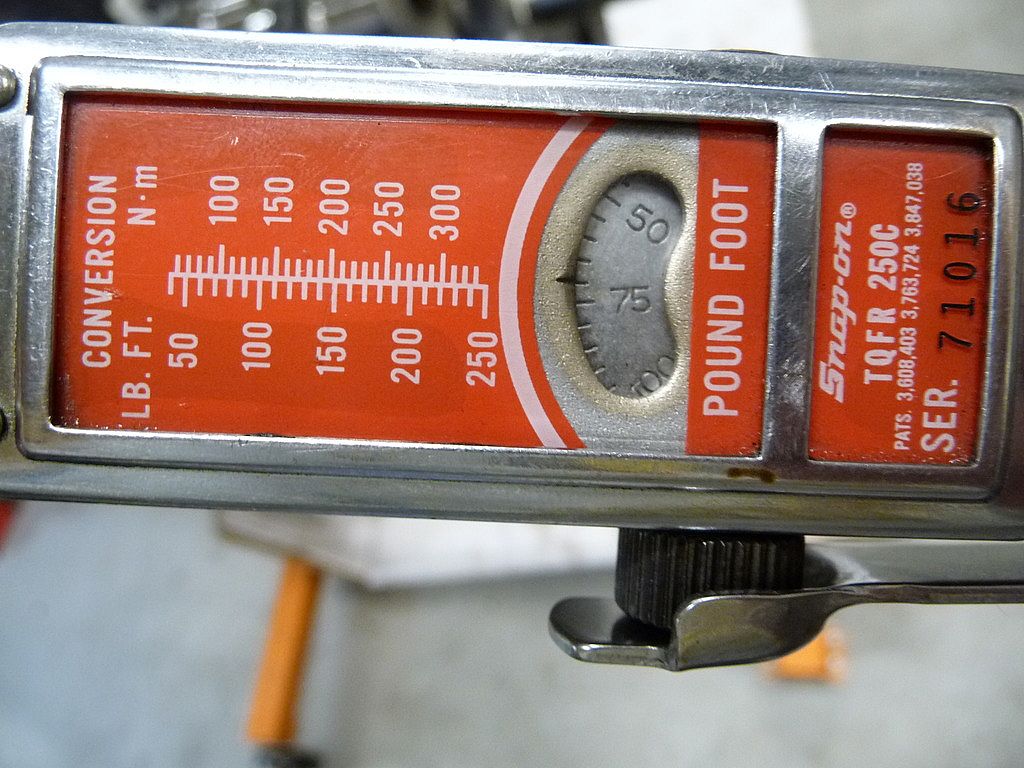

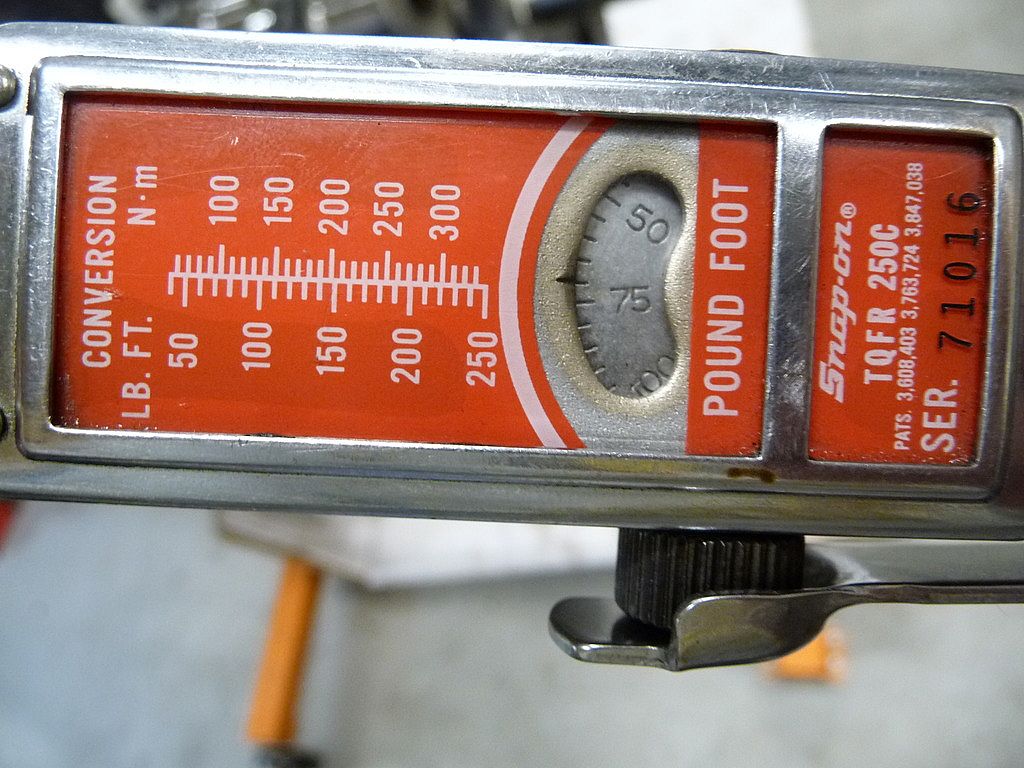

Snap on clicker

Decked .002

Everything is balanced

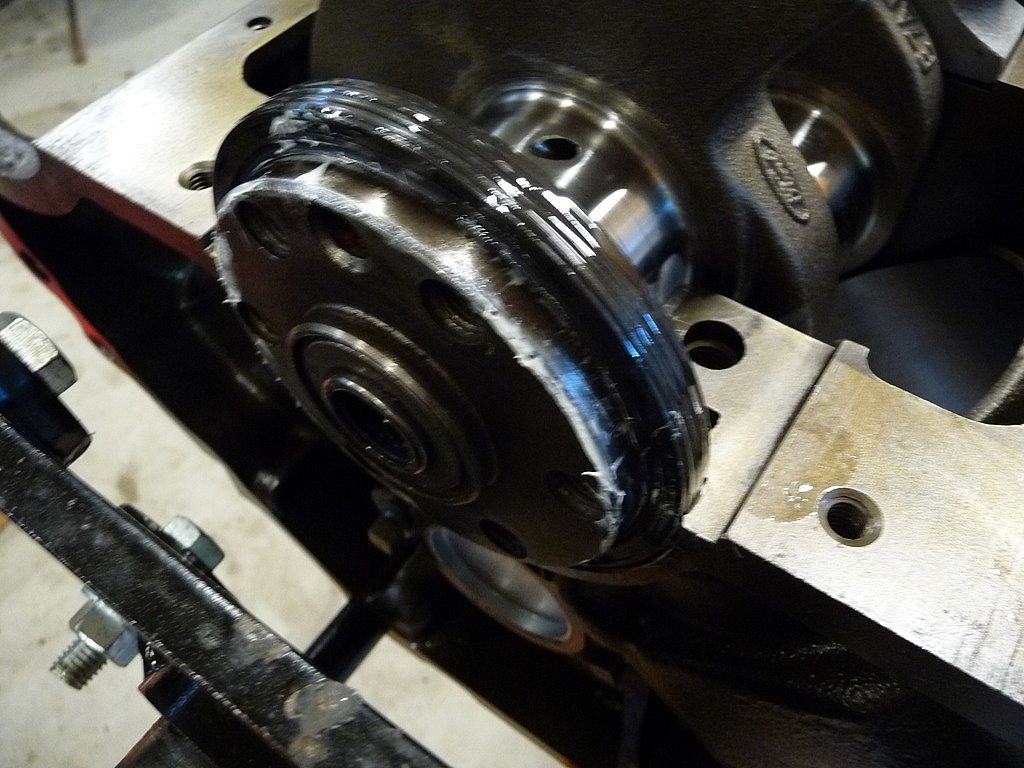

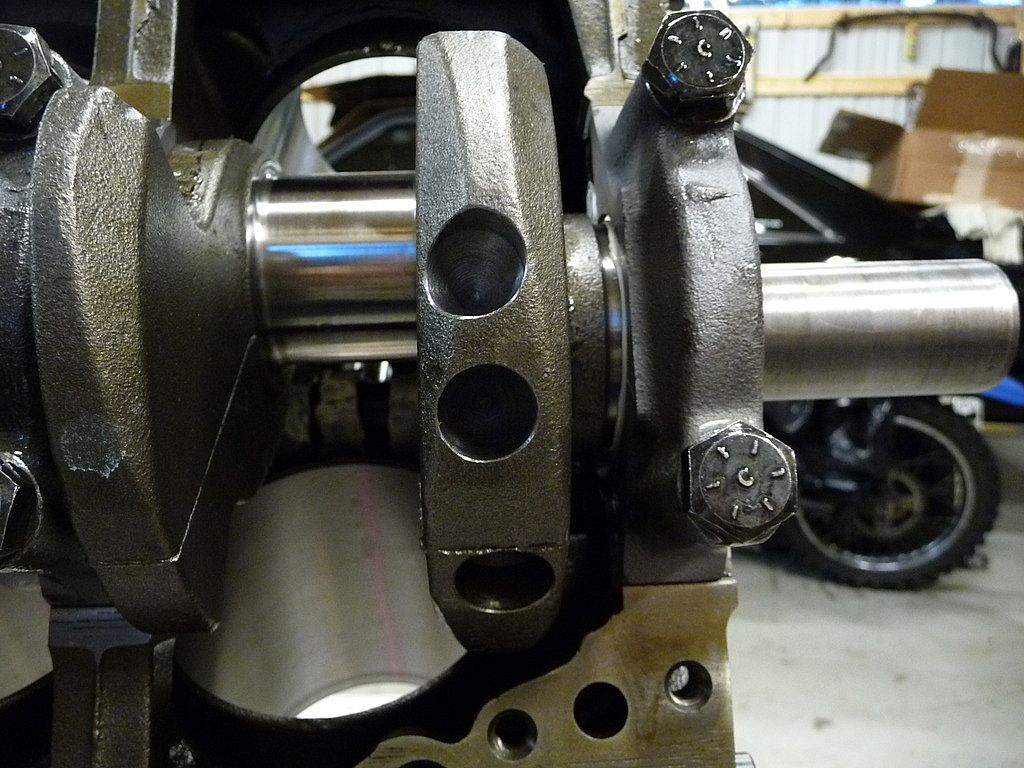

rod caps with material removed

Pistons were removed from rods and individually balanced

Lucky #7 was the lightest piston

Material was removed from each end of the crank to finally balance entire rotating assembly with balancer and flywheel included

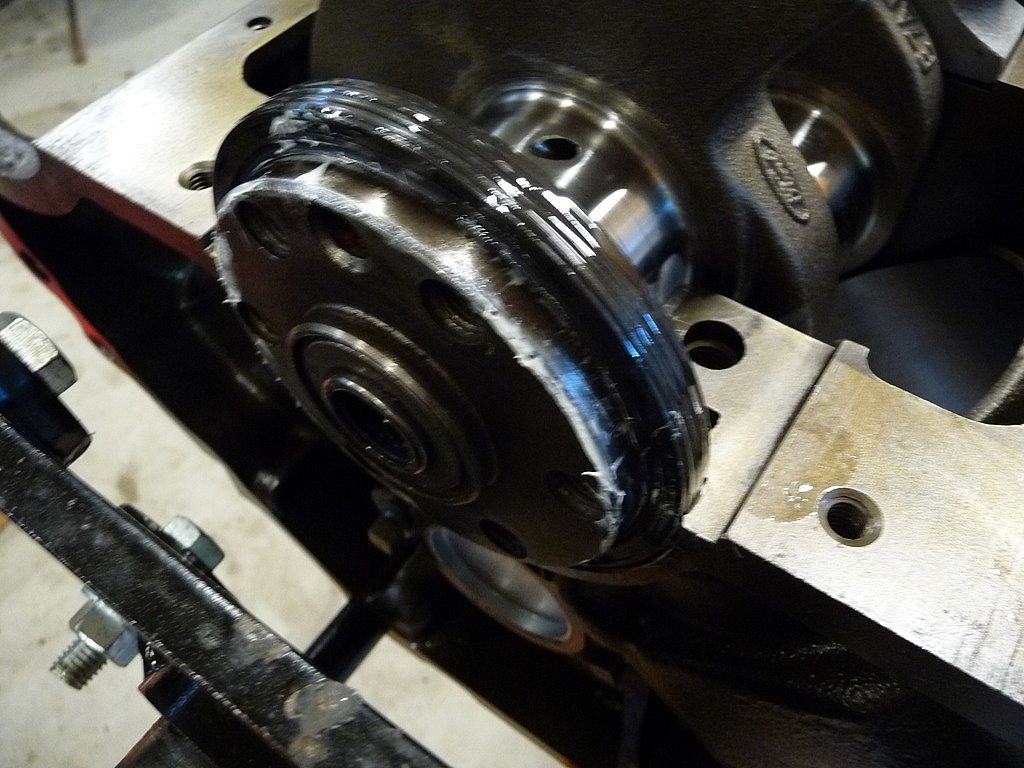

Rod bearing clearance

King race bearings instead of being beveled towards the crank side are cut narrower instead. Doesn't look right, but it is!

I torqued rod bolts with in/lb wrench - 240in/lb

Completed short block

Random work area

Machinist stamped crank

Main bearing clearances

Moly assembly lube

Rear main in

Crank installed

Snap on clicker

Decked .002

Everything is balanced

rod caps with material removed

Pistons were removed from rods and individually balanced

Lucky #7 was the lightest piston

Material was removed from each end of the crank to finally balance entire rotating assembly with balancer and flywheel included

Rod bearing clearance

King race bearings instead of being beveled towards the crank side are cut narrower instead. Doesn't look right, but it is!

I torqued rod bolts with in/lb wrench - 240in/lb

Completed short block

Random work area