UPDATE: Rear End Business

Now that Old Blue is more road worthy it was time to swap out the pitiful 273s (car still burned out at will with those slug gears, crazy). Here is SoCal there is an absolute wiz and all things differential. He has been in business for 25 years, builds rear ends for the local Ford dealers and did the rear ends for the Fast & Furious vehicles. It's a little hole in the wall, but the family owned business is LEGIT:

Ramjet Rear End

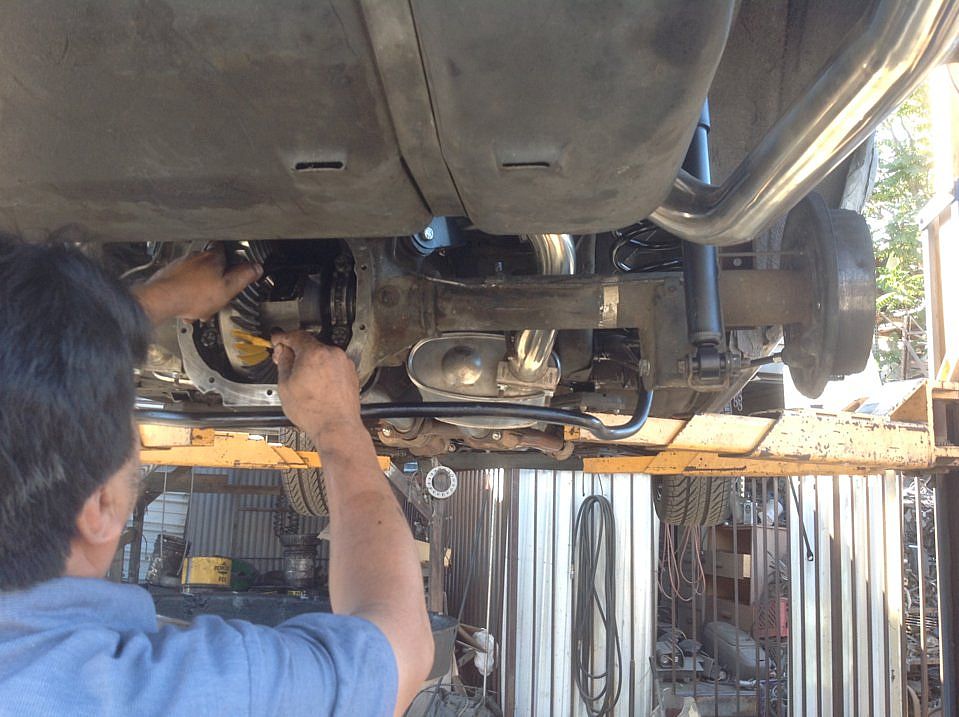

I drove the car in with 273s, one wheel spin, and, unknown to me, scarred up axles. Two and a half hours later I drove out with 355s, a rebuild traction lock with upgraded clutches, all new bearings, new axle bearings & seals, replacement axles, and a painted diff. Below are some pics in sequence:

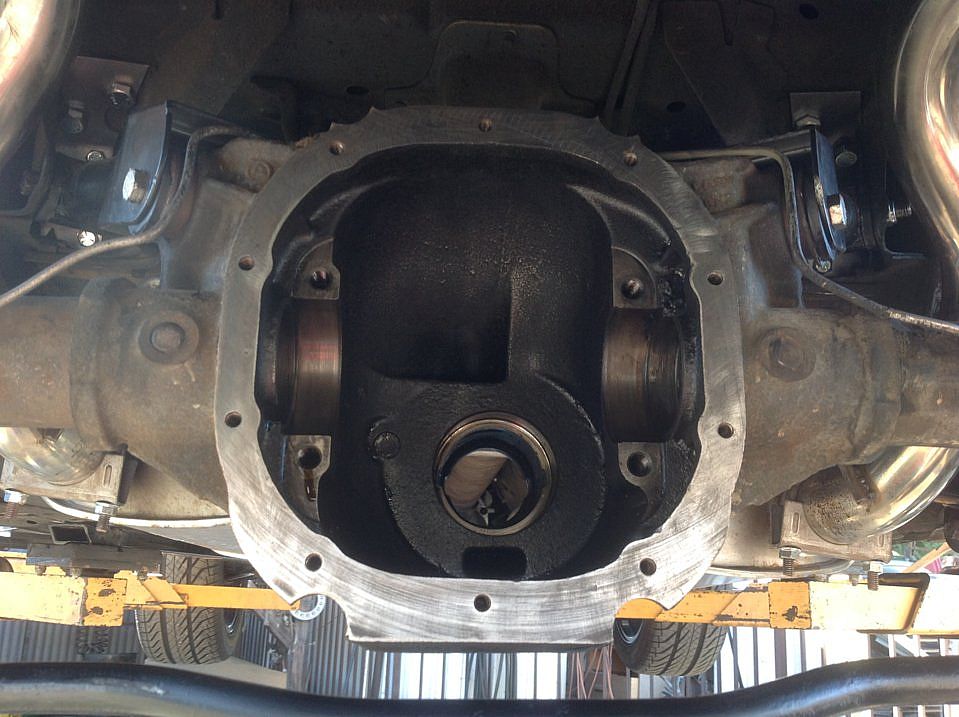

1)

2) Eddie -the owner/operator. The force is strong with this one.

3) Drain the old...

4) Only quality ingredients used here...

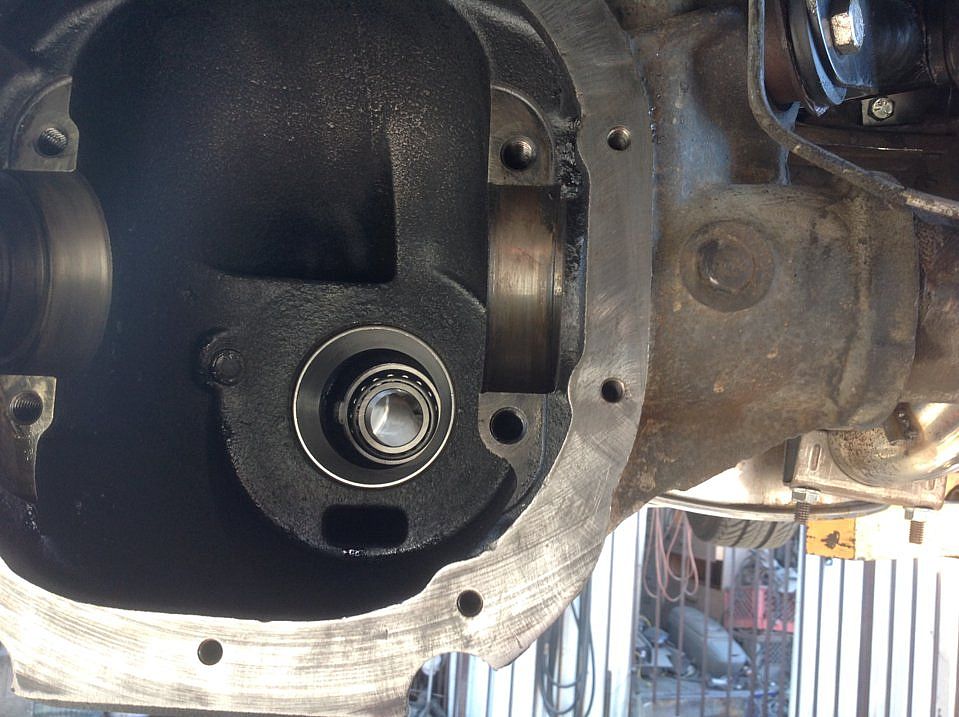

5) Remove burs, smooth out edges for less friction

6) Remove & Inspect old axles

7) Better than new

8) If one axle is bad replace both because this rear is 25 years old! FYI - Eddie prefers not to use new axles because they are usually made in China and are softer metal (28 and/or 31 spline). Instead he prefers good used axles as they are harder metal and will last longer. And, no, 31 spline is not needed unless your car is a (primarily) drag car and/or capable of lifting the front tires.

9) I can see straight through

10) I can see the red trans mount