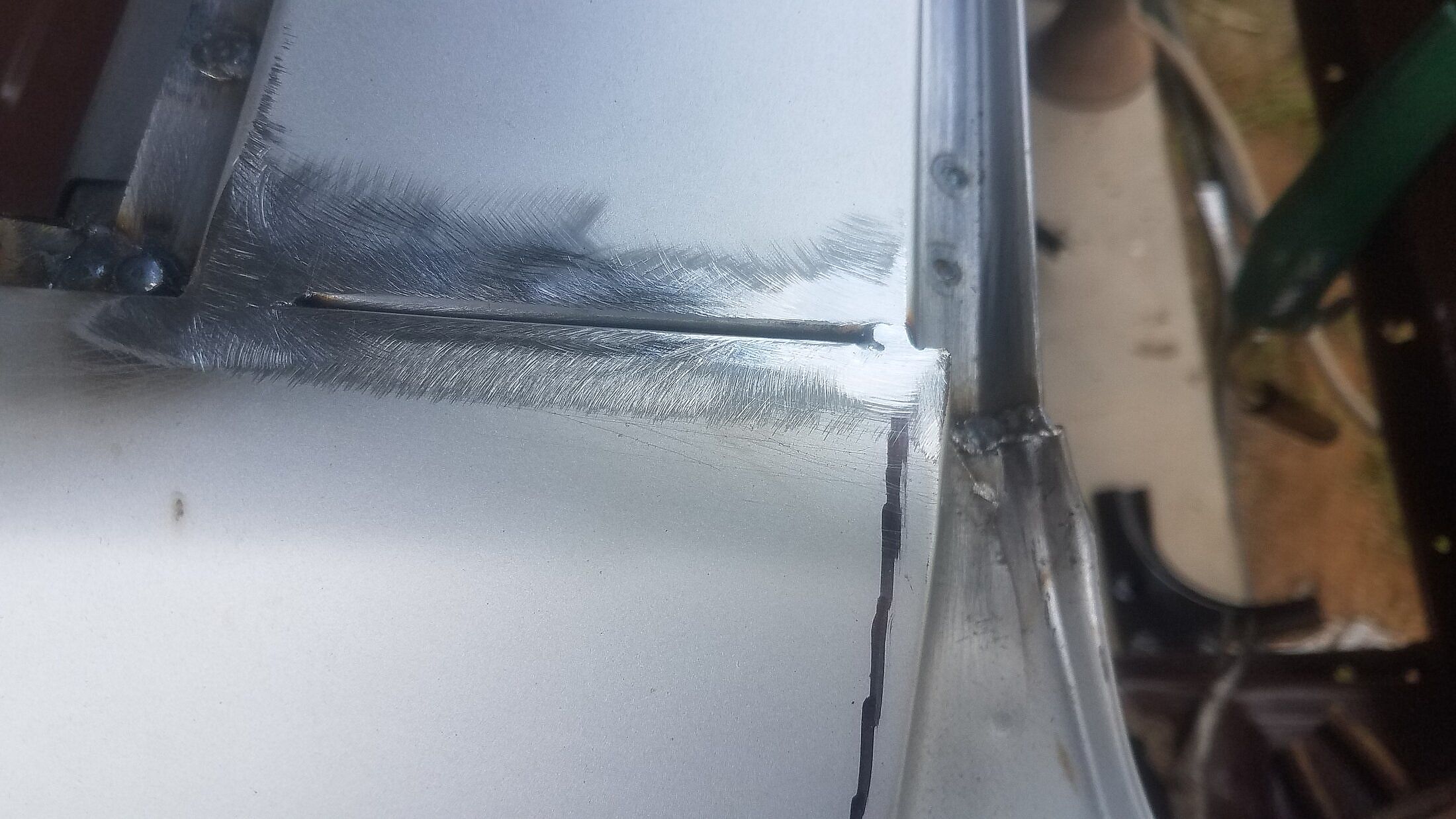

Shuuuuh! Dont make any loud noises ,you may scare my welder and the SOB is welding like never before!

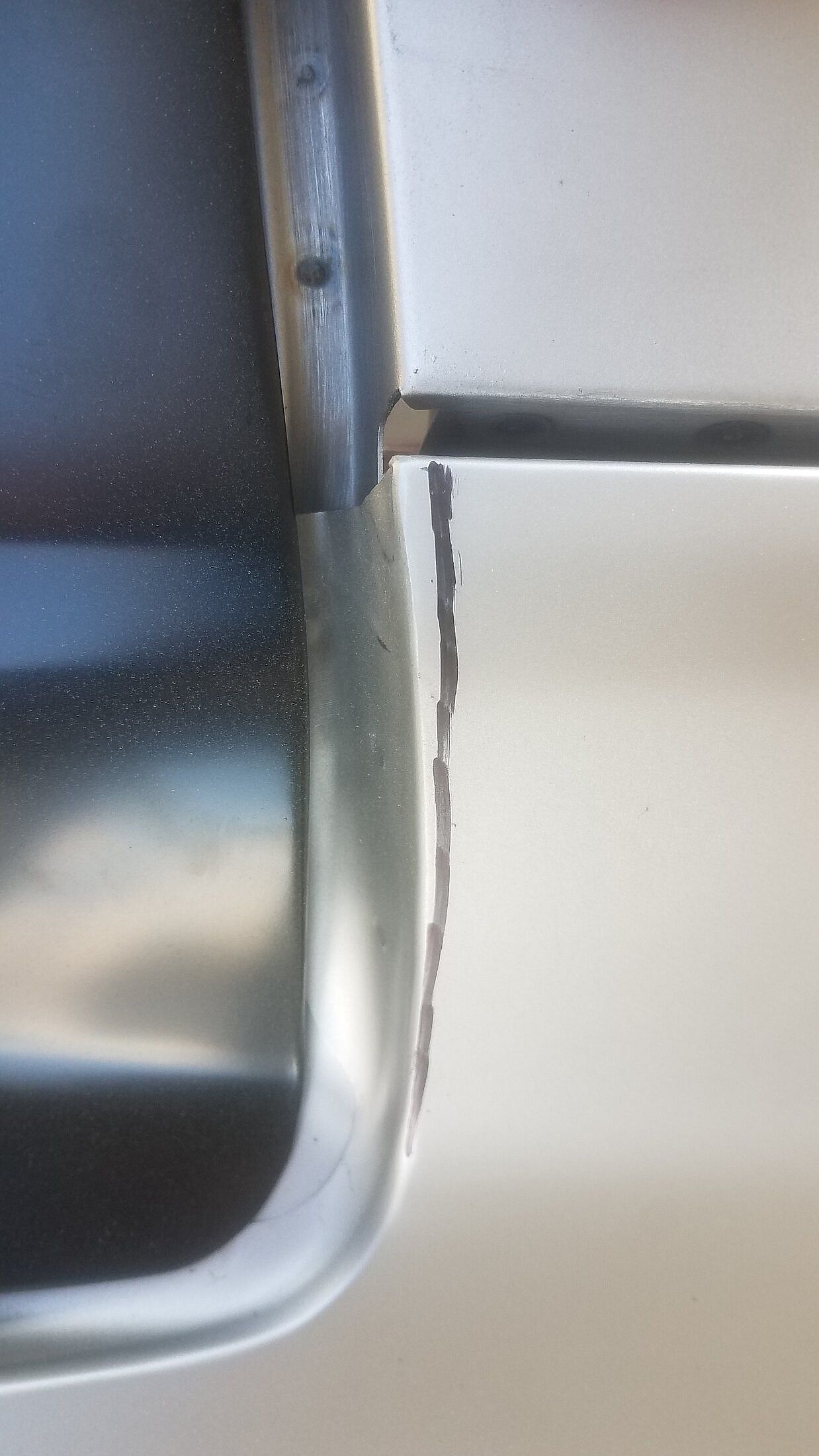

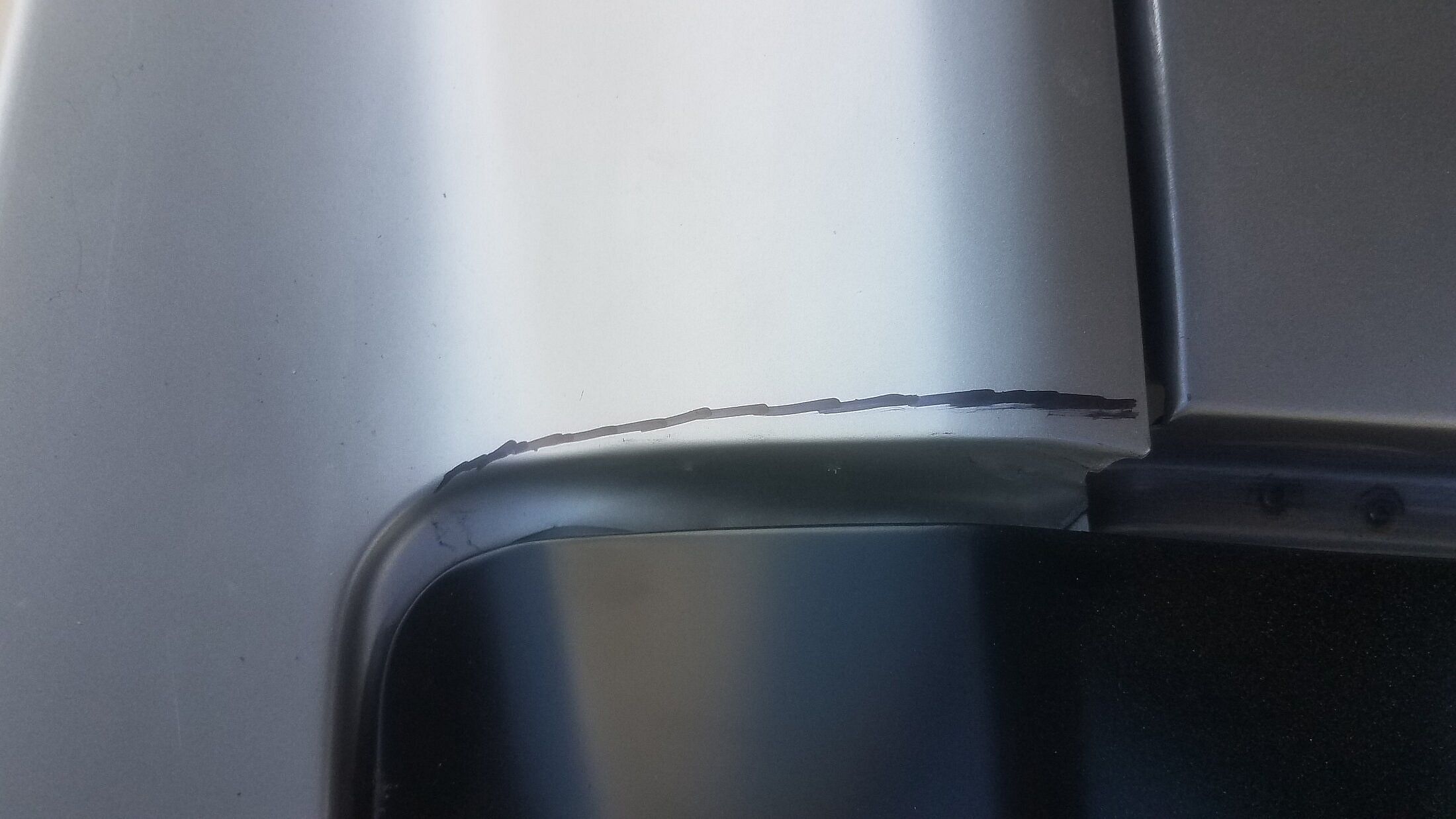

Got both door frames ,seat divider and the lower back window panel welded in .

That harbor freight spot welder ,you want one ,but you want the 220 not the 110! I have work tomorrow but if i am finished in time i am going to try to hang the quarters.

Got both door frames ,seat divider and the lower back window panel welded in .

That harbor freight spot welder ,you want one ,but you want the 220 not the 110! I have work tomorrow but if i am finished in time i am going to try to hang the quarters.