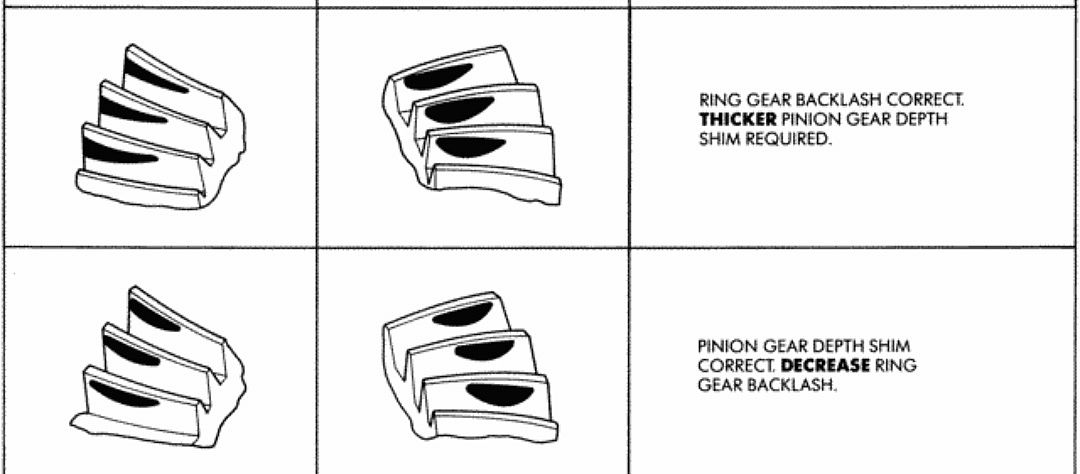

So Ive been working on installing a new set of Ford racing 3.73s. I've installed all new bearings, races and rebuilt the traction Lok while in there. I set the backlash with a magnetic dial indicator and put everything back tother. After getting the car together I took it out for a drive and noticed pretty bad gear whine when letting off the throttle. I only drove the car about 5 miles. I pulled the cover off and backlash was good and I checked the gear mesh and it looks something like one of these two

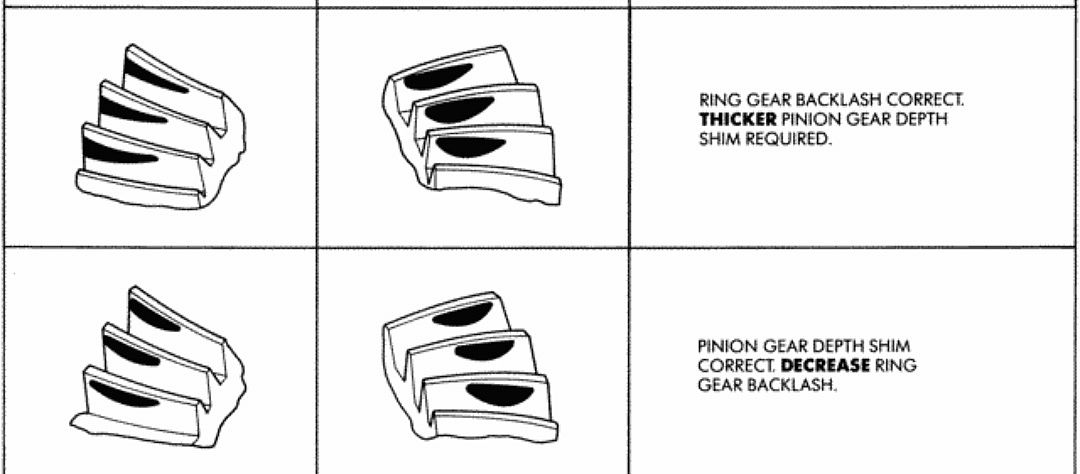

Now it more resembles the top one to me so I pulled the pinion out and this is what it looks like.

I assumed after checking the gear mesh that it needed another pinion shim but now after seeing this it makes me wonder. I though the backlash might have been a hair right when I put it together at about .008 so it doesn't seem like I should decrease it any like the above picture says. Just wondering what everyone's thoughts were. It also doesn't look like the pinon crush spacer has been crushed even a drop. It seemed like I was at the right amount of turning resistance with the inch pound torque wrench but maybe that needs to be tightened a little more. I was pulling on the 3/4 rachet about as hard as my skinny a$$ can but maybe it still needs more.

Just curious what everyone thinks. Not too sure on what to do just yet but know that I don't want the gear whine.

Now it more resembles the top one to me so I pulled the pinion out and this is what it looks like.

I assumed after checking the gear mesh that it needed another pinion shim but now after seeing this it makes me wonder. I though the backlash might have been a hair right when I put it together at about .008 so it doesn't seem like I should decrease it any like the above picture says. Just wondering what everyone's thoughts were. It also doesn't look like the pinon crush spacer has been crushed even a drop. It seemed like I was at the right amount of turning resistance with the inch pound torque wrench but maybe that needs to be tightened a little more. I was pulling on the 3/4 rachet about as hard as my skinny a$$ can but maybe it still needs more.

Just curious what everyone thinks. Not too sure on what to do just yet but know that I don't want the gear whine.