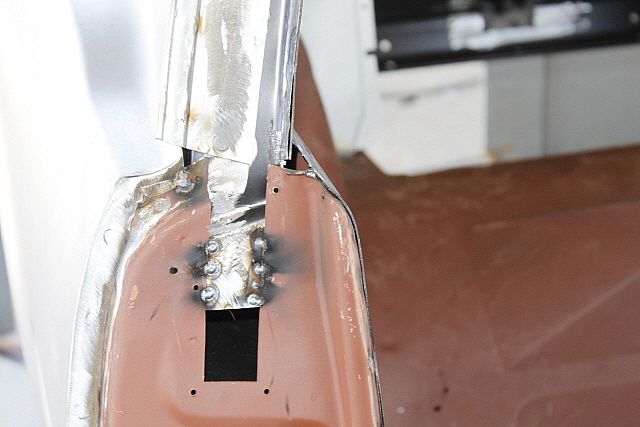

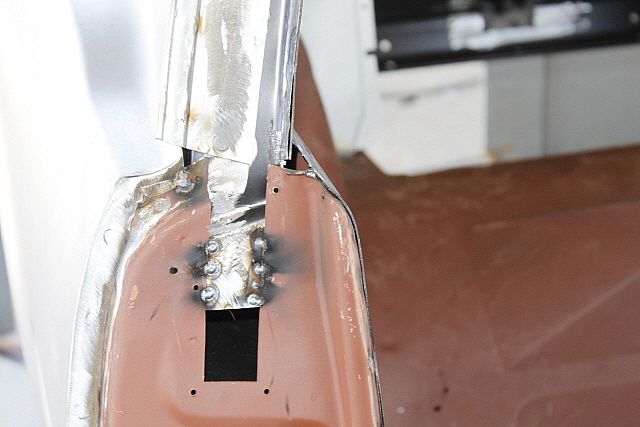

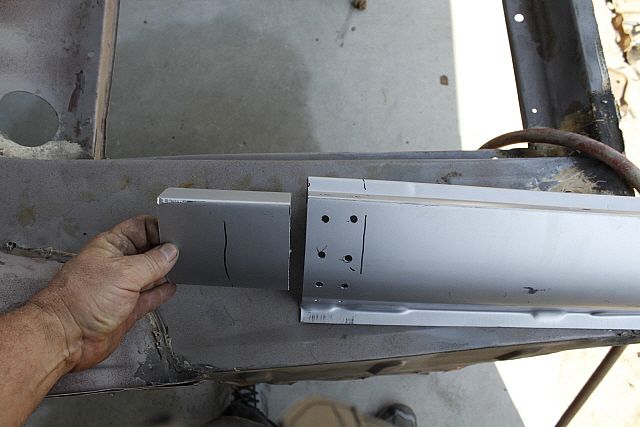

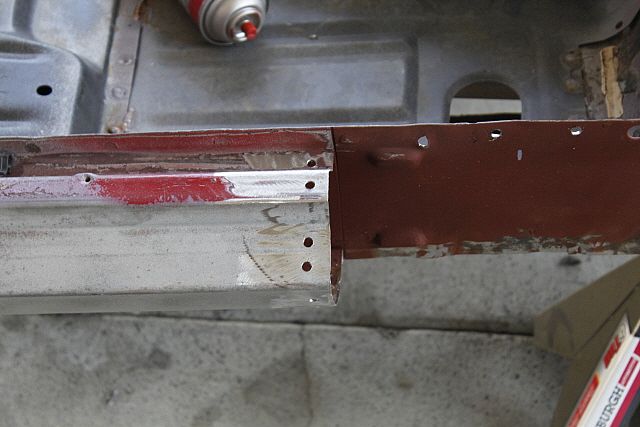

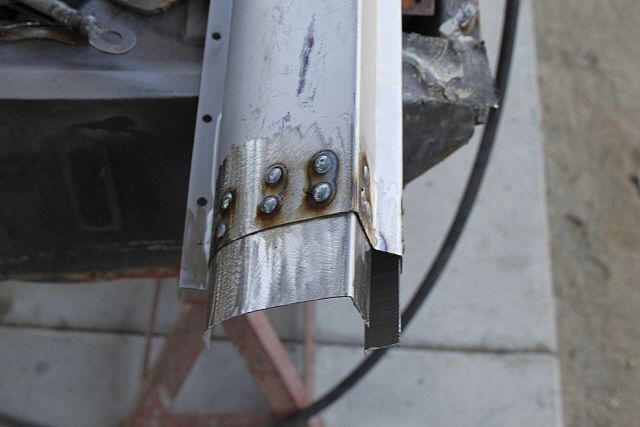

i got the inner structure finished just need to tie the door post to the roof brace on both sides. i still have to make the drip trays under the quarter vents and fill the quarter window holes in the rear door posts. i set this one up for shelby quarter windows but i need the drip trays because that is what the interior fiberglass attaches to. i got both torque boxes but not the floor supports and they have to go in first.supposed to get them tomorrow.soon as the torque boxes are in it is going up on the rotisserie to finish the rear wheel lips and sand blast the under side and prime.