I like torque numbers

It's always horsepower, horsepower, horsepower

Gimmie torque! I wanna pull a house down the road.

I guess it comes from drve'n a 'dump truck'

Thats it!

Sixes have clydesdale draft horses, V8's thorough-bred horses. As V8's gets bigger, the horses get more like Clydesdales again. Its like comparing a 4.9 F150 truck engine to a 5.0 Truck. Each has a vastly different behaviour to different driving conditions.

I drive a turbo diesel Isuzu FZR 12 ton truck. 7.8 liters of I6 and a nice big intercooled turbo sure helps it haul the 4 tons of bread inside its chiller.

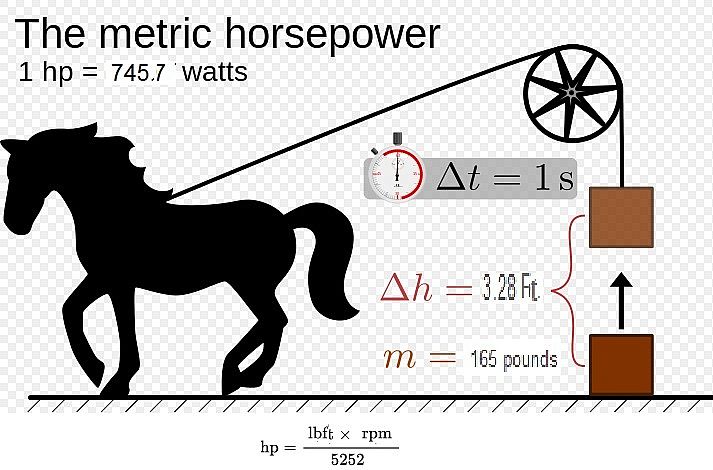

It's this ability to "do work" but "with speed" that is the key to driving up a steep grade. Torque is the abilty to peform the movement of a mass against gravity, essentially a "lift". Power exists because James Watt rated a horsepower as the ability to raise a 165 pound weight 3.28 feet in one second over a one revolution wheel hooked to a horses back. Some horses could do four times the work of others, but he averaged it as an inservice "spot check" quantity over an 8 hour day. Thats one of Mikes 4 speed overdrive gearboxes (165 pounds), hefted up just over three feet in a second.

Animals, people, bugs, they aren't like machines which are only able to give a percentage of there design power or torque. A whipped horse or person spoiling for a match race, they can exceed the actual minority report performance. A bug can sometimes exceed its normal jump height if it is spooked. An engine, it'll self destruct if its oversped or thrashed....it has no electrochemical stimulation to spike its performance...unless you give it Nawsss!

Working out peak torque is actually blQQdy hard, as power and torque are constant only when the wheel in the picture below is spining at 5252 rpm.

So 400 "CMA" Horsepower at 6000 rpm is 350 lb-ft at 6000 rpm.

Normally, peak toque is at peak volumetric efficency, down a factor 1.25 to 2.125 below the peak torque figure.

On a 1980-1982 255 Mustang 4.2 liter V8 or old 1969-1980 Ford 250 4.1, peak power was at 3400 rpm, and peak torque, 1600 rpm.

119 hp and 195 lb-ft or about 99 hp and 185 lb-ft, respectively. The difference between them was a 2-bbl verses 1-bbl carb.

On a Maserati 4200 GT, it has 385 hp at 7000 rpm and 333 lb-ft at 4500 rpm. The difference was 5 valves per cylinder, variable valve timing, resonant EFi intkae, and having a Ferrrari block to underpin it all.

As long as the CarMichael Angelo 250 ITB engine can do 5252 rpm, power in hp and torque in lb-ft, will always be equal at that speed. It is for all engines, all living things. Not every living thing can lift 165 pounds 3.3 feet in a second, so Hp and lb-ft is worked out by proportion.

I haven't tried loctite on a Black Widow, and gooping it to a line hooking it to a pulley, but the idea is the same for everything.

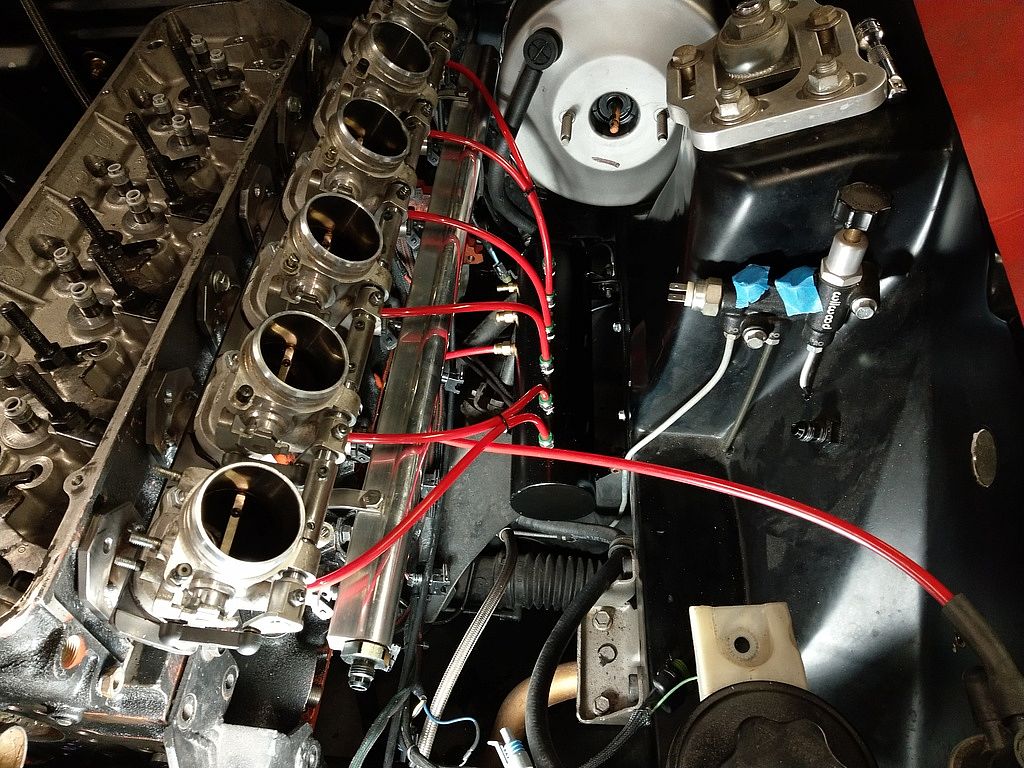

Not everything can cylce 5252 rpm. Mikes engine didn't used to go past 4800 rpm in the Maverick it was in. Now, it'll be hard pressed not to go past 6250 rpm when he gives it the Foot.

Mikes engine will hopefully pull its maximum power at about 6000 rpm, and its maximum torque at between 4800 to 4000 rpm.

Hopefully, it'll make more than 355 lb-ft at about 4800 rpm or maybee as low as 4000 rpm, but it will rise very sharply from its 750 rpm idle to those rpms, and lob or loft up in a gradual arch up to, hopefully, about 350 lb-ft at 6000 rpm, and make the 400 hp mark.

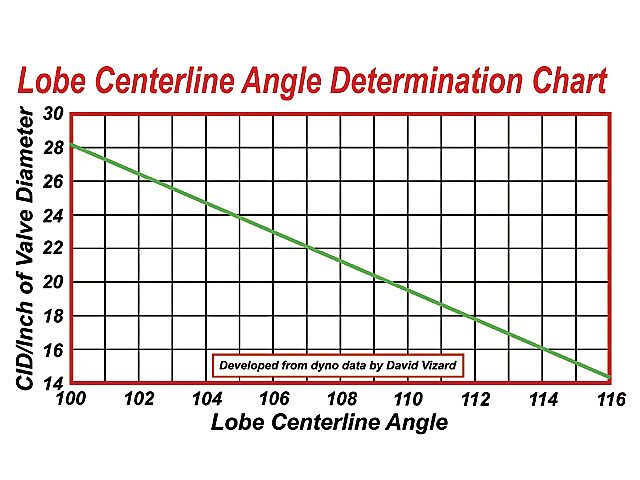

The classic American I6 HP increase is different to caming or modifiying a Detriot V8.

From that days of the 1952 Hudson Hornet Twin H to the last GM 4200, the I6 has space to make its intake take an extra bunch of intake tracts, and the power and torque growth is quite linear, even with much more radical cams.

On V8's, Detriot has been always keen to upsize the engine within the confines of the block.

A little 1962 221 Ford becoming a factory stroker 342 by 2002, or a 1955 265 Chev becoming a 400 in 1970, and remained popular for 10 years. These engines were core uses for siamesed bore 4-1/8" race blocks as used in Formula 5000 and some other power boat catagories.

A V8 normally grows its power by stroker capacity, and the popular class regulations normally keep away from ITB's on the basis of cost. In line sixes, regualtions allow for ITB's, but the engines are rpm constrained by crankshaft fatigue, which kicks in when revs go high enough to make about 375 hp from a 200 cube six.

Unlike V8's, sixes lap up and take H-U-G-E inital power and torque increases, much more than V8's, then past a 1985 NASCAR like 1.85 hp per cubic inch, they sharply reach a point of dimishing returns. The joy of V8's is how strong they are at 2.5 hp per cube. In line sixes comprehensivly die at that kind of power due to crank fatigue.

Building an I6 for torque is what Ford Australia did when it replaced the Clevelands. Adding a turbo aslways makes torque, but even so, a stock 1991 to 1997 EFi XR6 engine would make almost as much torque and power as as a stock XR8, the Mustang 5.0 HO EFi engine.

from you for the rest of the day.

from you for the rest of the day.