You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Engine This guy needs the help of this forum

- Thread starter Mcmahst

- Start date

-

Sponsors (?)

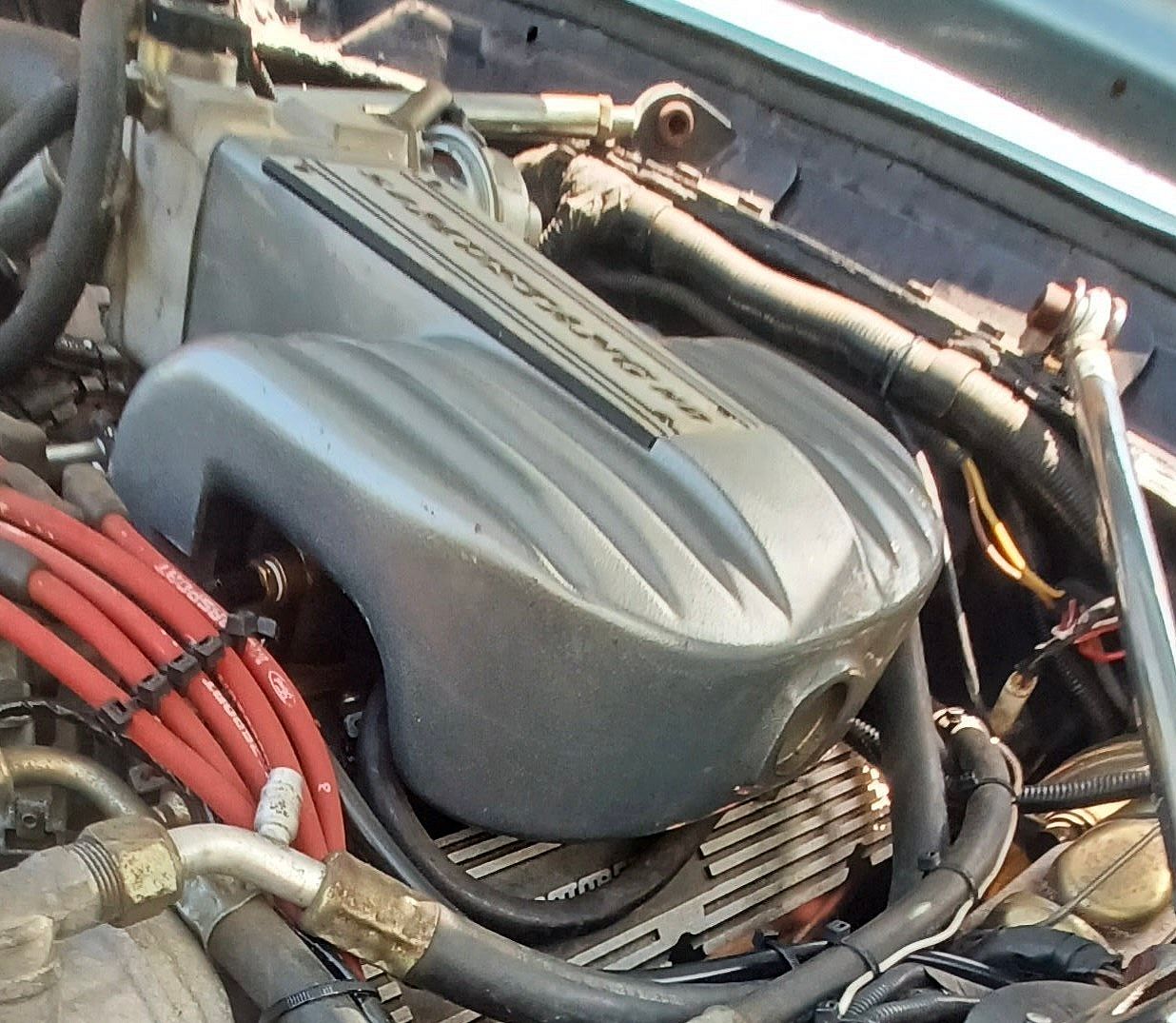

As a guy who spent his entire life in manufacturing, it doesn’t look like a one up by anybody with anything less than superior skills. It was obviously a multi cast pour with the plug on the back for the sand removal. So, even though I’ve searched everywhere and cannot find anything like it, is there any chance it was one sold by a manufacturer? It’s definitely not a modified upper. And since it’s pared with that thick EGR flange, it just looks like a company’s idea of an improved design. Maybe turned out to be a crap design, but who knows for sure.

The current owner told me the car changed hands twice after the work was done, so he has no idea who did the crate engine work.

The current owner told me the car changed hands twice after the work was done, so he has no idea who did the crate engine work.

I’ve never seen that intake before and have been in the fox game for 27 years now. If it was really an aftermarket casting then it would really need to be an obscure company that did it. Not a whole lot of folks were playing with HO intakes. Most focused on the lowers which was the major restriction.

I agree looks well done, but given what I’ve seen about the internal geometry of the stock HO intake I wonder if the #1 and #8 cylinder are being starved of air here.

I’d love to get my hands on it and see the casting numbers underneath.

But given that he has GT40 heads, he stands to gain by something like an explorer intake swap. I bet he would really feel that SOTP.

I agree looks well done, but given what I’ve seen about the internal geometry of the stock HO intake I wonder if the #1 and #8 cylinder are being starved of air here.

I’d love to get my hands on it and see the casting numbers underneath.

But given that he has GT40 heads, he stands to gain by something like an explorer intake swap. I bet he would really feel that SOTP.

Last edited:

b_arrington

Member

Hi all, I'm the guy that posted about this car on VMF. It's my son's 66 coupe with a 5.0 swap.

I want to thank @Mcmahst and @AeroCoupe for trying to help us dig into the motor. I'm pretty mechanically inclined, but trying to diagnose the complexities of this motor is new. In an effort to better maintain the car and help my son learn I've been digging into a bunch of stuff about the 5.0 and the EEC-VI controller.

The recent post on VMF was about gas milage. Long story short, he's getting about 9.5 mpg in around town driving, and we were trying to figure out if there was something amiss with the engine that needed to be corrected. And yes, I was getting a ton of "advice", so I decided to focus on getting codes and methodically diagnosing them.

I think a little background on this car, from the horse's mouth, is worth while. We got this as my 17 yo son's first car. We got it in part so he can learn about how to work on systems as he wants to study mechanical engineering. His mom has always loved Mustangs and after she introduced him to BaT he fell in love with the classic Mustang. She totally drove him getting this car.

As mentioned above, it's gone through a few hands since the engine was swapped. The story goes that a PO did a bunch of work on the car including adding what a valuation appraisal lists as a 1996 5.0L crate motor. (Frankly there are many in accuracies in the appraisal so I have zero confidence the year is correct). The owner then transferred the car to his sister to settle a debt. She sold it to the guy we bought it from. The records of the refurbishment and swap were not transferred so there's a lot of guessing and uncovering we've had to do.

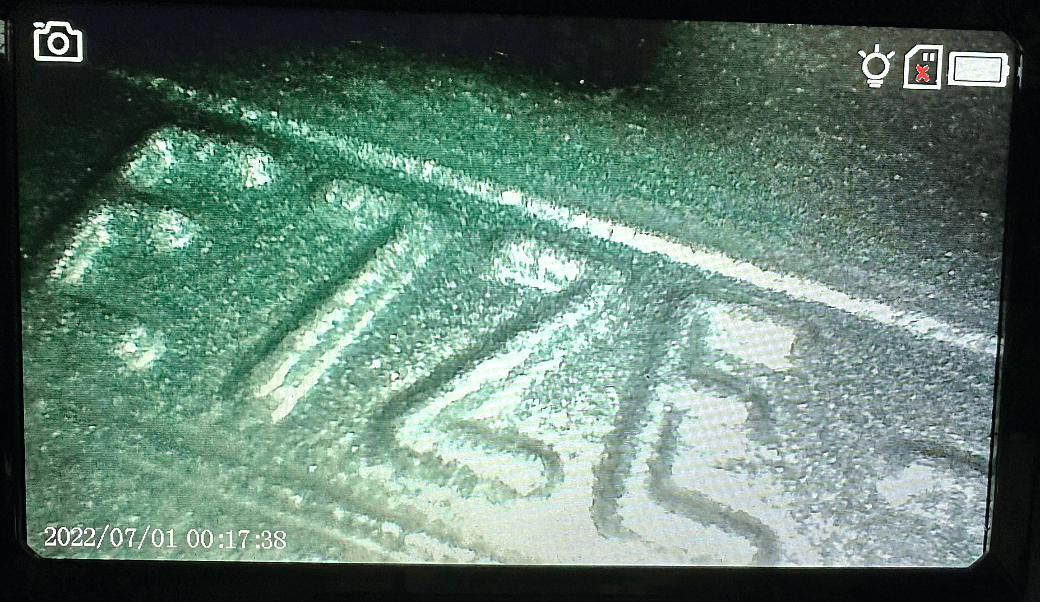

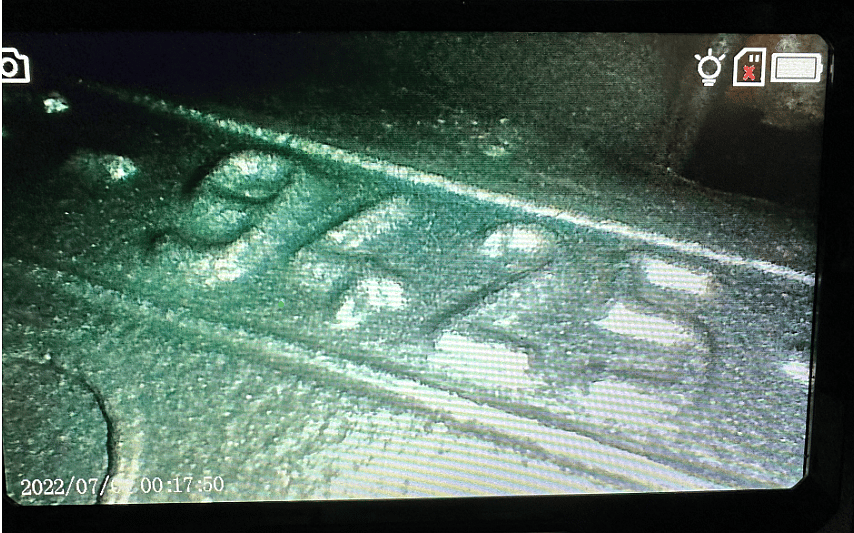

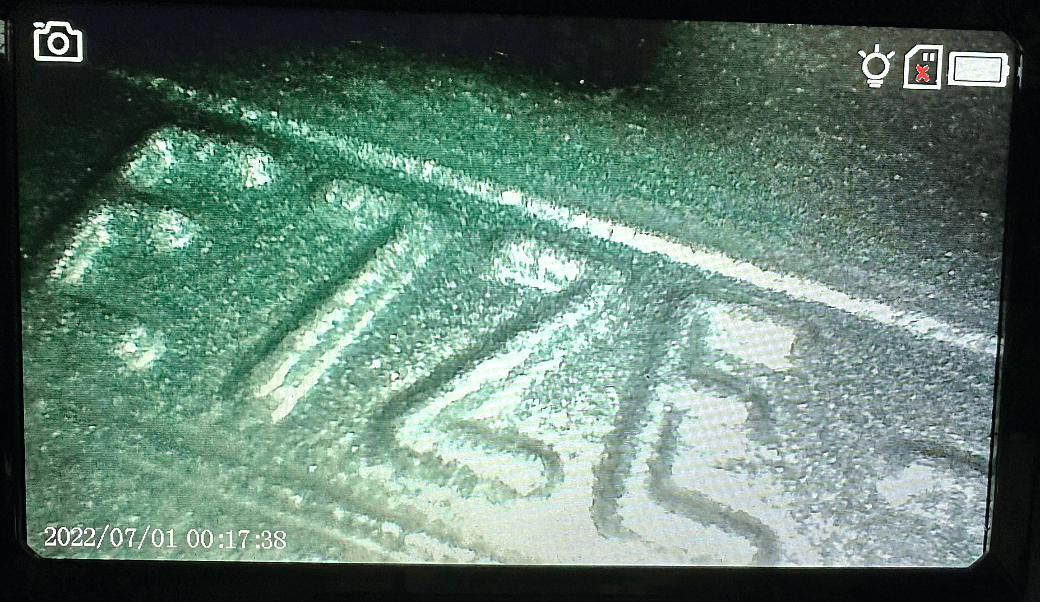

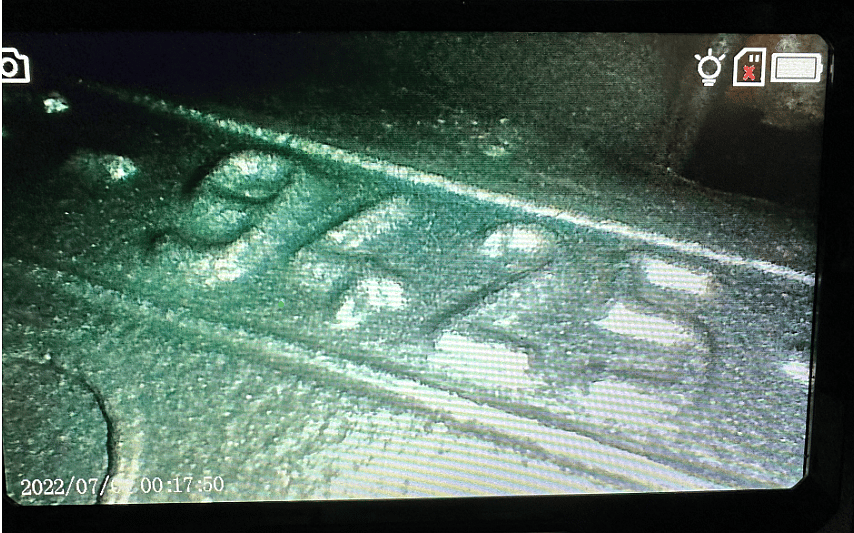

For example, that upper intake. We have no idea about the origin or why it's rounded. It looks to have been powder coated. I did go out this afternoon and look for some casting marks with my inspection camera. I found a partial casting mark: " -E7ZE-9425-". It looks like there were some other leading/trailing digits that are missing. Also, under the cover plate is a "H.O" marking.

IDK if it's significant, but I measured the throttle body intake to be 75mm.

As far as codes go, what we pulled is listed above. We've been trying to work on the 54 and 22 codes. Progress so far:

I want to thank @Mcmahst and @AeroCoupe for trying to help us dig into the motor. I'm pretty mechanically inclined, but trying to diagnose the complexities of this motor is new. In an effort to better maintain the car and help my son learn I've been digging into a bunch of stuff about the 5.0 and the EEC-VI controller.

The recent post on VMF was about gas milage. Long story short, he's getting about 9.5 mpg in around town driving, and we were trying to figure out if there was something amiss with the engine that needed to be corrected. And yes, I was getting a ton of "advice", so I decided to focus on getting codes and methodically diagnosing them.

I think a little background on this car, from the horse's mouth, is worth while. We got this as my 17 yo son's first car. We got it in part so he can learn about how to work on systems as he wants to study mechanical engineering. His mom has always loved Mustangs and after she introduced him to BaT he fell in love with the classic Mustang. She totally drove him getting this car.

As mentioned above, it's gone through a few hands since the engine was swapped. The story goes that a PO did a bunch of work on the car including adding what a valuation appraisal lists as a 1996 5.0L crate motor. (Frankly there are many in accuracies in the appraisal so I have zero confidence the year is correct). The owner then transferred the car to his sister to settle a debt. She sold it to the guy we bought it from. The records of the refurbishment and swap were not transferred so there's a lot of guessing and uncovering we've had to do.

For example, that upper intake. We have no idea about the origin or why it's rounded. It looks to have been powder coated. I did go out this afternoon and look for some casting marks with my inspection camera. I found a partial casting mark: " -E7ZE-9425-". It looks like there were some other leading/trailing digits that are missing. Also, under the cover plate is a "H.O" marking.

IDK if it's significant, but I measured the throttle body intake to be 75mm.

As far as codes go, what we pulled is listed above. We've been trying to work on the 54 and 22 codes. Progress so far:

- Pulled the ACT sensor, cleaned the sensor and pins, and bench tested for resistance. Checked OK and responded to heat. Cleaned the connector.

- Checked the voltage on the sensor with KOEO. Responded as normal, voltage changed with heat.

- BAP sensor. Removed the vacuum hose from the BAP and capped the hose.

- Checked the voltage going to the plug. Checked out at ~3.0v.

- Ran car. Engine seems to settle to idle much faster on start up. Exhaust seems less billowy.

- Pulled KOEO codes again and still getting all the same codes, including 54 and 22.

That intake appears to be a modified HO intake manifold. Why it was modified like that I have no idea but I’m not familiar with anyone doing that to a HO upper. Usually it’s the lower that gets a little massaging. Regardless, I don’t think it’s doing you any favors as I would suspect there might be some starvation going on in the #1 and #8 cylinders. But like mentioned a few times, give the GT40 heads you would gain quite a bit with an explorer intake swap.

Anyway, I do think the code 22 and 54 are critical and need to be solved before moving on. You state you have 3v at the sensor, when you should have 5v, so it’s possible this is a wiring issue.

Do you know what year wiring harness was used?

On the BaP, use a DVM to check for 5 volts on the orange/white wire. If it is missing, look for +5 volts at the orange/white wire on the TPS or EGR sensors Use the black/white wire for the ground for the DVM. Off the ECU, pin 26 is your 5v VRef. You’ll want to confirm you have 5 here but I would bet you do as you aren’t getting EGR and TPS codes.

As for the act, that’s pin 25 on the ECU connector. With the ECU connected measure the resistance from 25 to 46(sensor ground) and compare it to the resistance of the sensor itself. Should be similar.

The 10 pins are notorious for poor connection issues. It wouldn’t hurt to clean these up and spread the pins a bit to ensure a good connection.

Finally, don’t overlook ECU issues. At this point capacitors are likely to start failing. Also, if there is a wiring mismatch, you run the risk of damaging the ECU. This usually happens when an auto ECU is used with a manual oxygen sensor harness. There is a jumper on the harness the needs to be pinned correctly. Doing it incorrectly can actually burn out the pin 46 trace and you get all sorts of issues.

Id start with investigating the code 54 and 22 first. I’d check for 5v on the wiring leading to the BAP and then the resistance at pin 25 for the act. You could likely have poor connection.

Anyway, I do think the code 22 and 54 are critical and need to be solved before moving on. You state you have 3v at the sensor, when you should have 5v, so it’s possible this is a wiring issue.

Do you know what year wiring harness was used?

On the BaP, use a DVM to check for 5 volts on the orange/white wire. If it is missing, look for +5 volts at the orange/white wire on the TPS or EGR sensors Use the black/white wire for the ground for the DVM. Off the ECU, pin 26 is your 5v VRef. You’ll want to confirm you have 5 here but I would bet you do as you aren’t getting EGR and TPS codes.

As for the act, that’s pin 25 on the ECU connector. With the ECU connected measure the resistance from 25 to 46(sensor ground) and compare it to the resistance of the sensor itself. Should be similar.

The 10 pins are notorious for poor connection issues. It wouldn’t hurt to clean these up and spread the pins a bit to ensure a good connection.

Finally, don’t overlook ECU issues. At this point capacitors are likely to start failing. Also, if there is a wiring mismatch, you run the risk of damaging the ECU. This usually happens when an auto ECU is used with a manual oxygen sensor harness. There is a jumper on the harness the needs to be pinned correctly. Doing it incorrectly can actually burn out the pin 46 trace and you get all sorts of issues.

Id start with investigating the code 54 and 22 first. I’d check for 5v on the wiring leading to the BAP and then the resistance at pin 25 for the act. You could likely have poor connection.

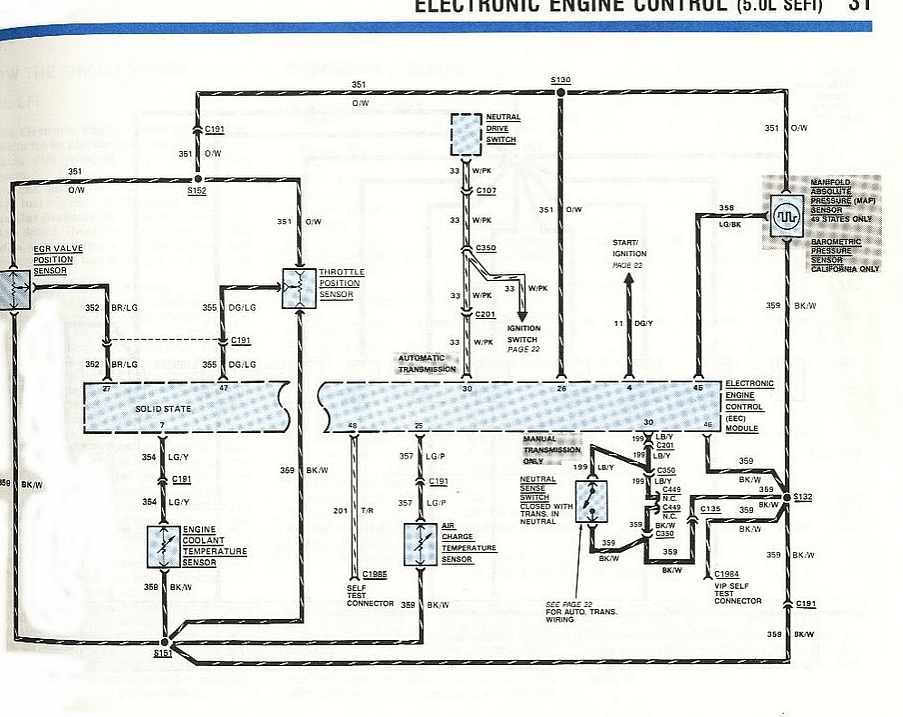

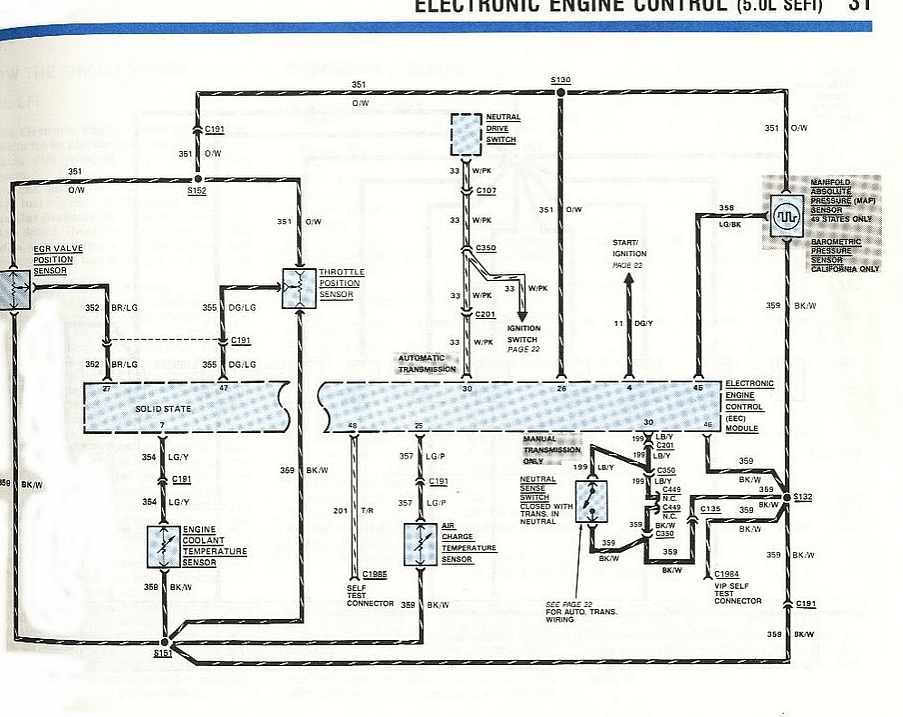

BTW here's a relevant wiring diagram

Pin 26 is your 5v Vref

Pin 46 is your sensor ground.

You want 5 V between those two pins and at the various sensors. You can see from the above diagram that the BAP sensor, the TPS, the EGR all share the same 5V pos and sensor ground. The MAP sensor is wired direct to the ECU through a single splice, ut the TPS and EGR go through the 10-pin connectors. So the 10=pins should have no bearing on if you have 5V at your BAP. You can use it to verify.

Your ACT is pin 25 to 46, and you can measure resistance at the ECU 60pin (with ECU pulled out) and verify it's the same as at the sensor. C191 is the connector name for the 10-pin, so you can see that the ACT also goes through the 10pin.

BTW the above is the 1988 wiring diagram (the only one i have a PDF of). I have the other years but would need to know what wiring harness year was used.

Full downloadable PDF is located here

stangnet.com

stangnet.com

Pin 26 is your 5v Vref

Pin 46 is your sensor ground.

You want 5 V between those two pins and at the various sensors. You can see from the above diagram that the BAP sensor, the TPS, the EGR all share the same 5V pos and sensor ground. The MAP sensor is wired direct to the ECU through a single splice, ut the TPS and EGR go through the 10-pin connectors. So the 10=pins should have no bearing on if you have 5V at your BAP. You can use it to verify.

Your ACT is pin 25 to 46, and you can measure resistance at the ECU 60pin (with ECU pulled out) and verify it's the same as at the sensor. C191 is the connector name for the 10-pin, so you can see that the ACT also goes through the 10pin.

BTW the above is the 1988 wiring diagram (the only one i have a PDF of). I have the other years but would need to know what wiring harness year was used.

Full downloadable PDF is located here

1988 Mustang EVTM

1988 Mustang EVTM SImilar to 1987 and 1989 with minor differences in engine harness. Most non-engine related stuff is identical, such as power windows, HVAC, defrost, etc.

Welcome to Stangnet. Getting that 5v nailed down is critical to solving the issues. You’ve got a great path forward from the last 2 posts.

b_arrington

Member

I went back and checked my notes on the BAP voltage test from earlier this week. It was actually 5v vs the 3v I stated before.

Thanks for the guidance. One question is, how do we test the pins on the ECU for proper signalling? One potential complication is the ECU is buried over the heater box, and access requires removal of the glove box. Not exactly fun or easy on a ’66, and it tends to stress the carboard material of the box.

Oh, here’s a pic of the ECU.

Thanks for the guidance. One question is, how do we test the pins on the ECU for proper signalling? One potential complication is the ECU is buried over the heater box, and access requires removal of the glove box. Not exactly fun or easy on a ’66, and it tends to stress the carboard material of the box.

Oh, here’s a pic of the ECU.

That’s a 1993 ECU for a 5.0 automatic mustang. Here is the wiring diagram for a 1991 - 1993 Mustang. I suspect you do have a 93 harness.

Attachments

Here is the site I got the above from, I’ve used it in the past for ECU info:

It’s hard to test the BAP sensor without an oscilloscope. There is the Texton 127, but it may be cheaper to buy a new a new BaP and give it a shot. I hate firing the parts cannon off at things without troubleshooting.

WHat i'd do in this case is test continuity from the Light Green/black on the BAP down to pin 45, and then the black/white to pin 46. I'd be looking to see if the wire is broken.

You're call if you want to try and trace out the wires to the ECU (you'd have to unplug it) or just buy a BAP and give it a shot. If it doesn't work and you keep getting the code, you'll need to trace the wires anyway.

FOr the ACT, i'd test at the 10pin connector for the moment. Black/white to light green/purple and see if your resistance value matches.

Also, I agree with the assumption that you likely have a 93ish harness to match the ECU, but one thing to check is the jumper position on the O2 sensor harness.

See this thread. You'll want to se post #14 and 15.

stangnet.com

stangnet.com

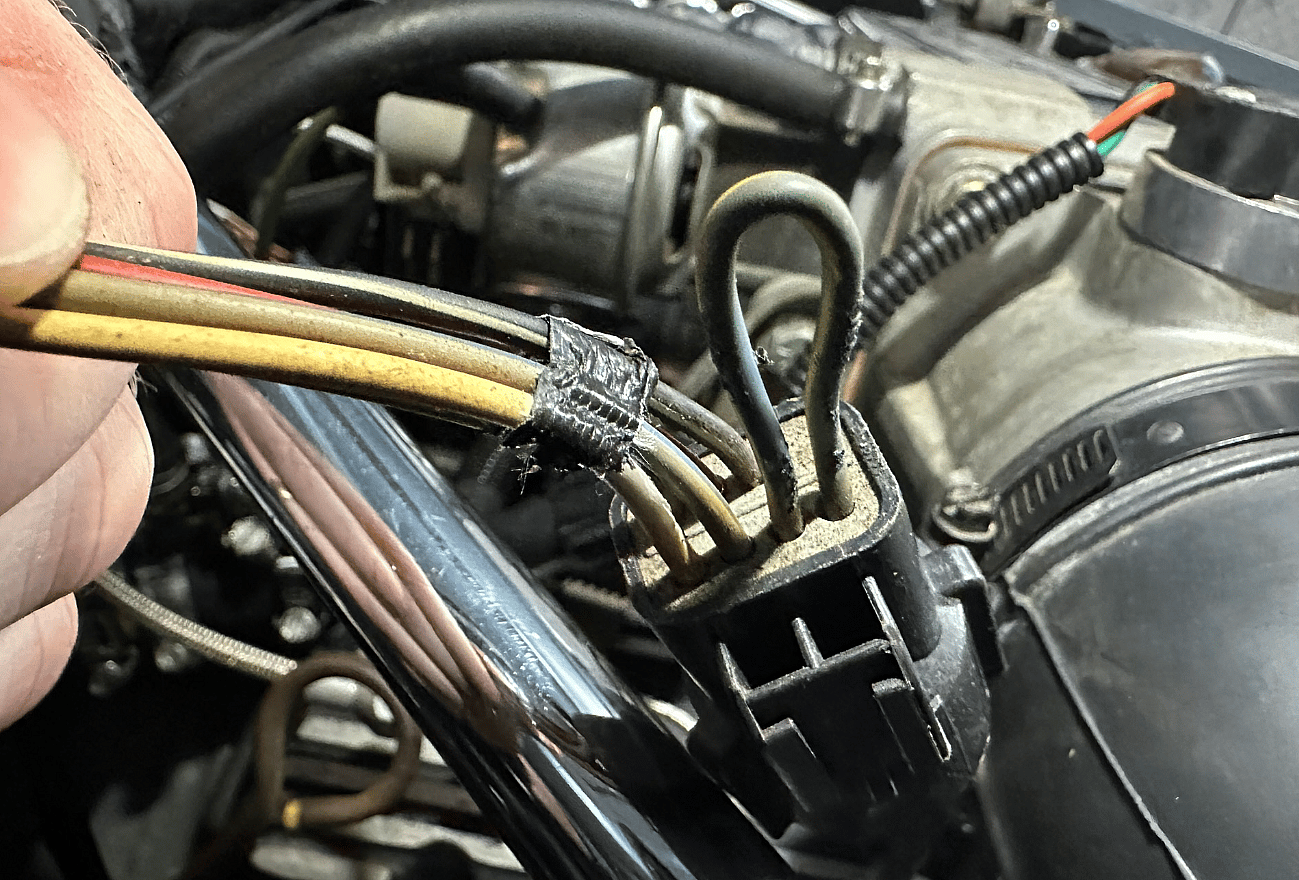

This harness should be on the pass side of the engine where the harness drops under the engine to feed the O2 sensors. There's a loop that needs to be pinned specific to trans and ECU.

Sorry to throw so much info at you but it gives you enough to keep progressing if you check things out and haven't solved it. Also, you may want to periodically erase the codes, give the engine a few start cycles and then repull. SOmetimes old codes hang around.

ANd finally if you are brave and want to check the ECU. I know it's a PITA but these ECU's are notorious for cap failures and pin 46 burnouts and require a little service.

View: https://www.youtube.com/watch?v=p73aWm9OXbU

WHat i'd do in this case is test continuity from the Light Green/black on the BAP down to pin 45, and then the black/white to pin 46. I'd be looking to see if the wire is broken.

You're call if you want to try and trace out the wires to the ECU (you'd have to unplug it) or just buy a BAP and give it a shot. If it doesn't work and you keep getting the code, you'll need to trace the wires anyway.

FOr the ACT, i'd test at the 10pin connector for the moment. Black/white to light green/purple and see if your resistance value matches.

Also, I agree with the assumption that you likely have a 93ish harness to match the ECU, but one thing to check is the jumper position on the O2 sensor harness.

See this thread. You'll want to se post #14 and 15.

Electrical - O2 harness repin

This thread is a HOW-TO for the process of repining the o2 sensor harness to match ECU/Trans, in the event the car is swapped. See post 15 as to what the jumper should be repinned to. Step one. Remove the o2 sensor harness from vehicle. I find it easier to do on a bench plus it allowed me to...

This harness should be on the pass side of the engine where the harness drops under the engine to feed the O2 sensors. There's a loop that needs to be pinned specific to trans and ECU.

Sorry to throw so much info at you but it gives you enough to keep progressing if you check things out and haven't solved it. Also, you may want to periodically erase the codes, give the engine a few start cycles and then repull. SOmetimes old codes hang around.

ANd finally if you are brave and want to check the ECU. I know it's a PITA but these ECU's are notorious for cap failures and pin 46 burnouts and require a little service.

View: https://www.youtube.com/watch?v=p73aWm9OXbU

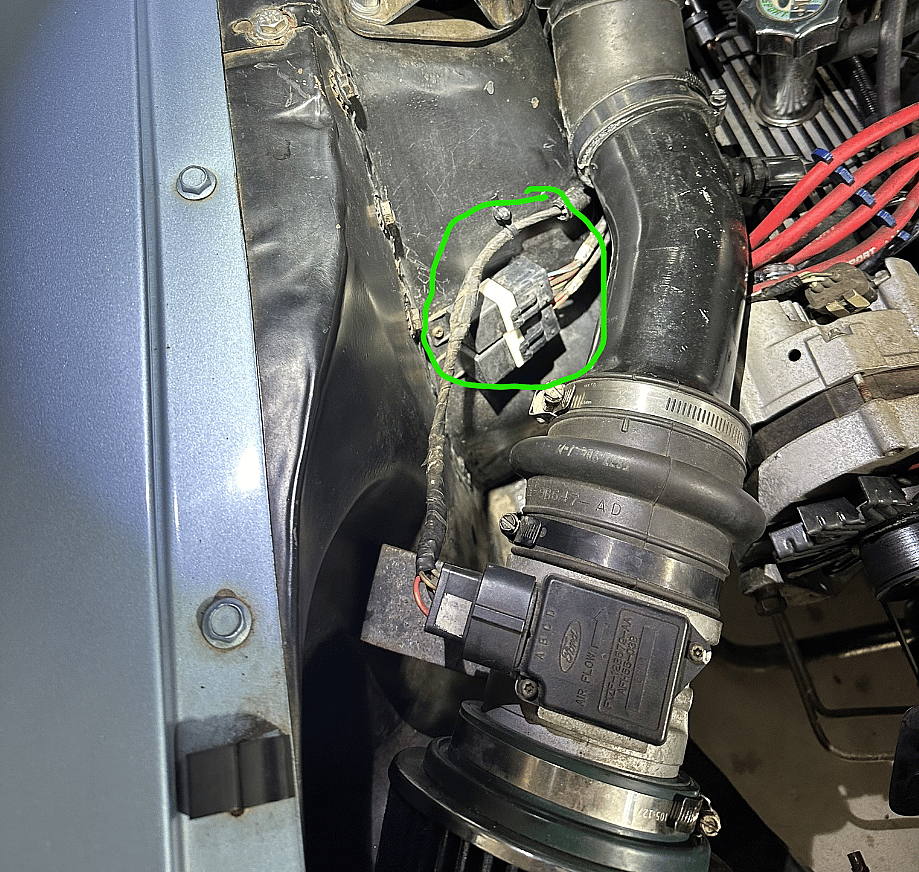

So the absolute way to determine if you have a mid 92 through 93 engine harness is the location of the fuel pump and AC compressor relays. They are both next to the mass air meter. This picture shows the mass air meter plug (black oval four pin) and the two relays attached to their corresponding plugs:

b_arrington

Member

Thanks for this. I was wondering how to ID what harness I have.So the absolute way to determine if you have a mid 92 through 93 engine harness is the location of the fuel pump and AC compressor relays. They are both next to the mass air meter. This picture shows the mass air meter plug (black oval four pin) and the two relays attached to their corresponding plugs:

Based on this, it seems we have 92/93 harness. The wires for the MAF are much longer than in your photo, but the two relay connections are nearby, mounted to the front of the shock tower below the air intake tube.

b_arrington

Member

It’s hard to test the BAP sensor without an oscilloscope. There is the Texton 127, but it may be cheaper to buy a new a new BaP and give it a shot. I hate firing the parts cannon off at things without troubleshooting.

WHat i'd do in this case is test continuity from the Light Green/black on the BAP down to pin 45, and then the black/white to pin 46. I'd be looking to see if the wire is broken.

You're call if you want to try and trace out the wires to the ECU (you'd have to unplug it) or just buy a BAP and give it a shot. If it doesn't work and you keep getting the code, you'll need to trace the wires anyway.

FOr the ACT, i'd test at the 10pin connector for the moment. Black/white to light green/purple and see if your resistance value matches.

Also, I agree with the assumption that you likely have a 93ish harness to match the ECU, but one thing to check is the jumper position on the O2 sensor harness.

See this thread. You'll want to se post #14 and 15.

Electrical - O2 harness repin

This thread is a HOW-TO for the process of repining the o2 sensor harness to match ECU/Trans, in the event the car is swapped. See post 15 as to what the jumper should be repinned to. Step one. Remove the o2 sensor harness from vehicle. I find it easier to do on a bench plus it allowed me to...stangnet.com

This harness should be on the pass side of the engine where the harness drops under the engine to feed the O2 sensors. There's a loop that needs to be pinned specific to trans and ECU.

Sorry to throw so much info at you but it gives you enough to keep progressing if you check things out and haven't solved it. Also, you may want to periodically erase the codes, give the engine a few start cycles and then repull. SOmetimes old codes hang around.

ANd finally if you are brave and want to check the ECU. I know it's a PITA but these ECU's are notorious for cap failures and pin 46 burnouts and require a little service.

View: https://www.youtube.com/watch?v=p73aWm9OXbU

Thanks for this detail, I appreciate the advice and different avenues! I also don't like throwing parts at an issue, but in this case I think trying a replacement BAP sensor would be reasonable. I don't have access to an o-scope, so I can't test it.

It seems evident we need to try some clean up on the 10 pin connectors. That's not going to be fun. No that cleaning and spreading the contacts is too hard, but for the fact they are mounted in a bit of a tough area on the fire wall so access is hard. Double checking that the ACT sensor plug is making good contact is probably a good idea to.

I hear you about the codes. We did erase them before the last drive and then pulled them after probably 2 start cycles. But I agree that sometimes they persist. Right now is very cold and snowy so I'm not super fond of driving the car around in the salt so it may take some time to repull them.

O2 Sensor harness. I pulled the plug to check the jumper for an AOD. It's correct.

For testing the ECU itself, I understand how to check resistance and continuity with a DMM while it's disconnected. What's unclear is how to do that when it's connected to the harness in a KOEO scenario. Some guidance or a link to how to do this would be super!

Explorer intake swap. Read a bit on this and understand it in general. I'm not yet convinced we have the GT40 headers; trying to look for the 3 bars on the header confirm that. I found the the stamping for the the current lower in take and it reads as RF-E6SE-9K461-Dxx.

What's not clear to me yet is if we can just take a stock Explorer upper intake and reuse the existing throttle body. Should it bolt right on? The current throttle body has a 75mm intake, which it seems like is not a stock setup for either a Mustang or an Explorer.

Now this is opening a can of worms and I think we should focus on the codes first. But in researching the Explorer upper intake, I was reading that Exploers typically used 24lb injectors. Ours uses 19lb that matches the standard MAF. That MAF has quite a restriction on the inlet, going down to like 55mm. It seems like that larger 75mm throttle body and better flow from an Explorer upper would not doing much with an upstream restriction at the MAF, and it might make sense to replace it with a less restrictive one like from Pro-M. If we did that, we could replace the injectors with 24lb since the intake would be off anyway and get the new MAF tuned to the higher flow injectors. IDK if this logic tracks or how much gain we would have with this.

Explorers used 19# injectors and a 65mm TB.

I’m not sure I would tackle an intake swap at this point. I’d get the car running well first.

I’m not sure I would tackle an intake swap at this point. I’d get the car running well first.

b_arrington

Member

I agree. And just to be clear, the car seems to be running fine, it’s not stalling or stumbling. The complaint is the terribly poor mileage of about 9.5 mph.Explorers used 19# injectors and a 65mm TB.

I’m not sure I would tackle an intake swap at this point. I’d get the car running well first.

I think you may have 4 cylinders running lean and 4 others running pig rich. I mean... Our sensors and ECM are incapable of balancing individual cylinders. It will only do banks.

Just a thought. I have no idea what the inside of that intake looks like.

Just a thought. I have no idea what the inside of that intake looks like.

On a side note: I keep getting glimmers of 'Deja vu' when I see that intake but cannot for the life of me, recall where or if I've seen it before.

Similar threads

- Replies

- 15

- Views

- 1K

- Replies

- 2

- Views

- 533

- Replies

- 1

- Views

- 809

- Replies

- 20

- Views

- 3K

- Replies

- 40

- Views

- 5K