I haven't had a chance to drive it in a few days. But it certainly feels like it's coming right through the trans. I did just have the rear main seal fixed with a new clutch etc. Maybe it wasn't installed properly. Would you feel it with out without the clutch pressed?If you're sure it's confined to shifter/trans, it sure sounds like a throw-out bearing. Preload should be 5-7#.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ridiculous vibration

- Thread starter Renob89gt

- Start date

-

Sponsors (?)

Every time I have ever had a bad vibration felt through the shifter it has been the trans itself.

Yes,..why you would be advised to ck firing order for an RPM based vibration is beyond me. An engine with plug wires crossed ( firing order OUT of order) runs like a turd at all RPMs,...You have an imbalance issue.I'll double check the firing order today. Would this not make the car run rough? Seems to run and start well.

Prior experience with the HO and non HO firing order mix up.Yes,..why you would be advised to ck firing order for an RPM based vibration is beyond me. An engine with plug wires crossed ( firing order OUT of order) runs like a turd at all RPMs,...You have an imbalance issue.

A person can fiddle with the timing enough to make it run good enough, all you do is schlep back and forth to car shows all you notice is an annoying vibration, yeah, you can barely pass a prius, but I think he never drove it over 35-40 mph.

No it was not my car.

It came into the shop because the pulley fell off the harmonic balancer. Apparently several times.

Now you can ask 'what does a rear main seal have to do with a unbalance problem'.

A bit of a delay here, 3 month old baby keeps you pretty busy. Add in wifes bday and mothers day and well no time for the car. I have only drove it to the pizza shop down the street, so I haven't had much time to feel it out much more. I did notice two things though, one is about the shifter sitting higher. when I had the clutch done, we swapped out the trans mount to the SVE heavy duty trans mount (red one on their site). I have the ford performance hurst shifter from American muscle, but now the rubber located around the bottom of the shifter hits the plastic trim piece that snaps on over the shifter boot. If its the trans is sitting higher, would it still cause a vibration even though im sitting still (clutch in or out). The other thing I noticed is that if I keep going past 3k and into the 4-5 k range I start to feel the vibration in my butt. Trying to get any and all thoughts out the way before I pull the trans again.

U-Joints

Get under the car and shake, rattle, and roll each one to see if there is any give or movement.

Get under the car and shake, rattle, and roll each one to see if there is any give or movement.

So we checked the clearance of the shifter and it's all good. I know prothane bushings on the cross member changes things a bit but I can't see it changing the vibration this much and only during 3k and up? The video doesn't really show much, but the shifter goes from the normal shake (due to x cam) to a much faster more aggressive shake when I rev it up to about 3k. I can also feel it in the seat of my ass pretty good when I get it to 3k and up. Again, this is sitting still. Or going, with clutch in or out. The trans shifts pretty smooth when driving, only issue is a slight grind when shifting into 3rd if I'm getting on it hard.

It sure sounds like an imbalance problem like when the wrong year parts get put on. That’s a rpm dependent shake from heck, the cam should smooth out with only a few RPMs.

Did you have the flywheel refaced with the new clutch or did you change it?

If all cylinders pass the balance run test, that points to something physical.

EDIT: new Poly vs. rubber mounts are not going to make the car shake that much or not if it is running and spinning right. I hear some hum, but not vibration above idle with poly.

A loose tailshaft will not Vibrate when the car is still. It will when moving, but it is not RPM dependent,

Did you have the flywheel refaced with the new clutch or did you change it?

If all cylinders pass the balance run test, that points to something physical.

EDIT: new Poly vs. rubber mounts are not going to make the car shake that much or not if it is running and spinning right. I hear some hum, but not vibration above idle with poly.

A loose tailshaft will not Vibrate when the car is still. It will when moving, but it is not RPM dependent,

Last edited:

The harmonic balancer and fly wheel are brand new 50oz. I don't have the ability to do a compression test would have to ask my mechanic buddy.It sure sounds like an imbalance problem like when the wrong year parts get put on. That’s a rpm dependent shake from heck, the cam should smooth out with only a few RPMs.

Did you have the flywheel refaced with the new clutch or did you change it?

If all cylinders pass the balance run test, that points to something physical.

I am not talking about a compression test. After you check for codes, there is another test to run that drops power to one cylinder at a time. I will see if I can find jrichker’s how to on it.

Gotcha. I know when my buddy had the trans out doing the clutch he pulled off the oil pan to replace a leaky oil pan gasket and said things were looking good from what he could see. LolI am not talking about a compression test. After you check for codes, there is another test to run that drops power to one cylinder at a time. I will see if I can find jrichker’s how to on it.

Btw, new parts does not Always mean right parts. Things can be put in the wrong box along the line or made incorrectly.

Here is the post from @jrichker I think you need.

-Cylinder balance test: use this to find dead or weak cylinders:

Revised 09-Sep-2017 Added reminder to write down the stored codes and engine running codes.

The computer has a cylinder balance test that helps locate cylinders with low power output. You’ll need to dump the codes out of the computer and make sure that you have the A/C off, clutch depressed to the floor and the transmission in neutral. Fail to do this and you can’t do the engine running dump codes test that allows you to do the cylinder balance test.

Here's the way to dump the computer codes with only a jumper wire or paper clip and the check engine light, or test light or voltmeter. I’ve used it for years, and it works great. You watch the flashing test lamp or Check Engine Light and count the flashes.

Be sure to turn off the A/C, have the clutch depressed to the floor, and put the transmission in neutral when dumping the codes. Fail to do this and you will generate a code 67 and not be able to dump the Engine Running codes.

Here's how to dump the computer codes with only a jumper wire or paper clip and the check engine light, or test light or voltmeter. I’ve used it for years, and it works great. You watch the flashing test lamp or Check Engine Light and count the flashes.

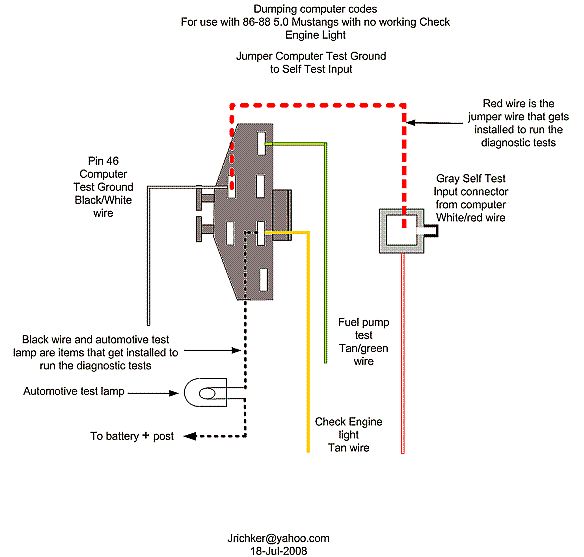

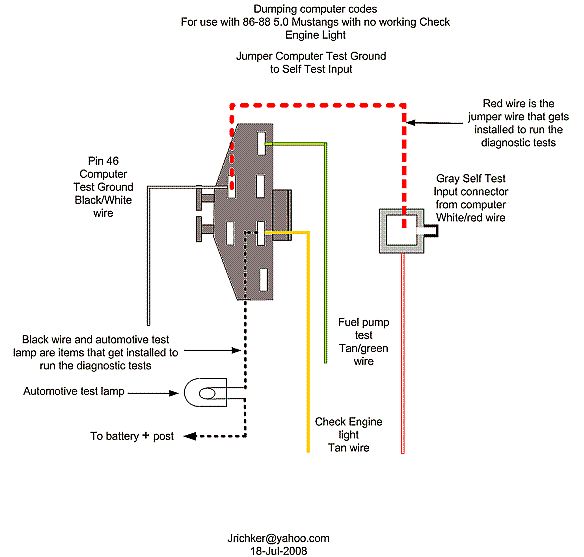

If your car is an 86-88 stang, you'll have to use the test lamp or voltmeter method. There is no functional check engine light on the 86-88's except possibly the Cali Mass Air cars.

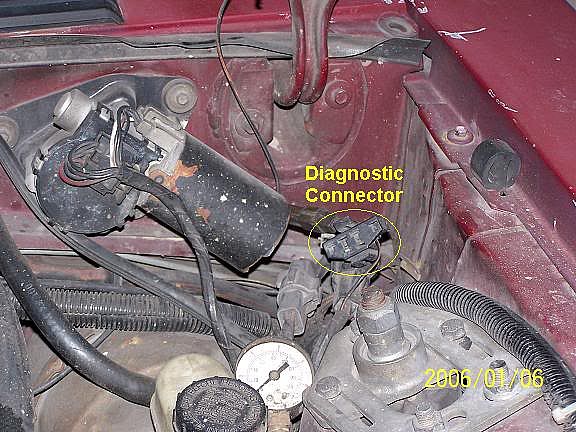

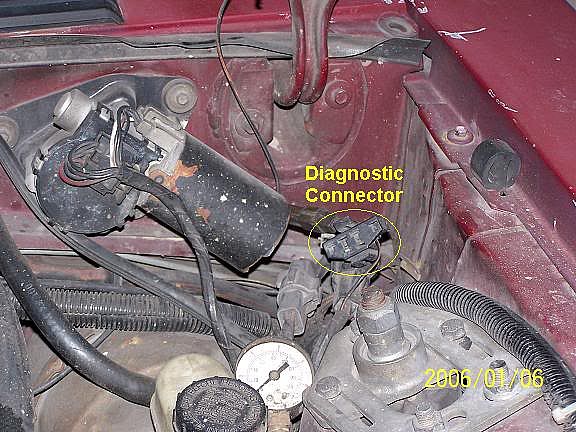

The STI has a gray connector shell and a white/red wire. It comes from the same bundle of wires as the self test connector.

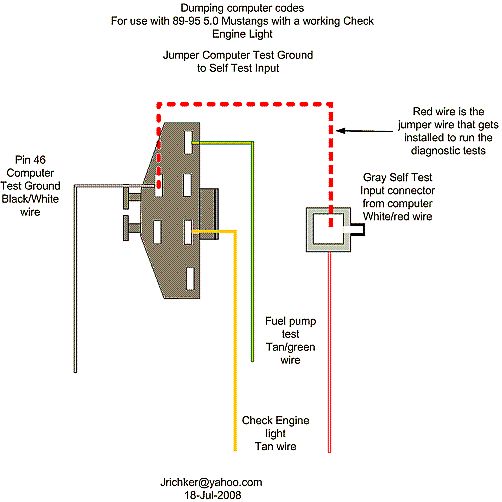

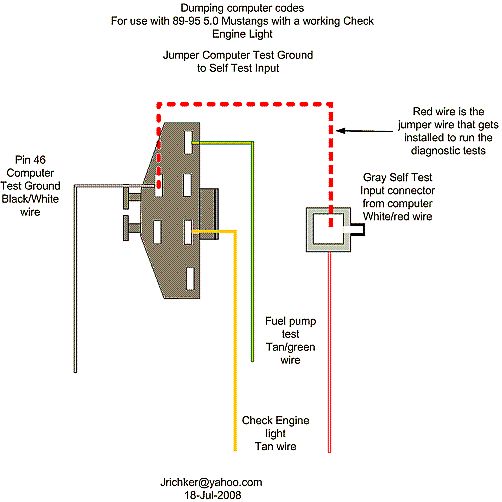

89 through 95 cars have a working Check Engine light. Watch it instead of using a test lamp.

The STI has a gray connector shell and a white/red wire. It comes from the same bundle of wires as the self test connector.

WARNING!!! There is a single dark brown connector with a black/orange wire. It is the 12 volt power to the under the hood light. Do not jumper it to the computer test connector. If you do, you will damage the computer.

What to expect:

You should get a code 11 (two single flashes in succession). This says that the computer's internal workings are OK, and that the wiring to put the computer into diagnostic mode is good. No code 11 and you have some wiring problems.

This is crucial: the same wire that provides the ground to dump the codes provides signal ground for the TPS, EGR, ACT and Map/Baro sensors. If it fails, you will have poor performance, economy and drivability problems

Some codes have different answers if the engine is running from the answers that it has when the engine isn't running. It helps a lot to know if you had the engine running when you ran the test.

Dumping the Engine Running codes: The procedure is the same, you dump the codes and then you start the engine with the test jumper in place. Be sure the A/C is off, clutch depressed to the floor and the transmission is in neutral. You'll get an 11, then a 4 and the engine will speed up to do the EGR test. After the engine speed decreases back to idle, it will dump the engine running codes.

Trouble codes are either 2 digit or 3 digit, there are no cars that use both 2 digit codes and 3 digit codes.

Your 86-88 5.0 won't have a working Check Engine Light, so you'll need a test light.

See AutoZone Part Number: 25886 , $10

Alternate methods:

For those who are intimidated by all the wires & connections, see Actron® for what a typical hand scanner looks like. Normal retail price is about $30 or so at AutoZone or Wal-Mart.

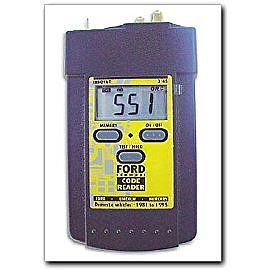

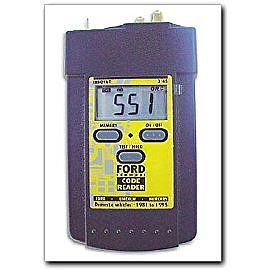

Or for a nicer scanner see www.midwayautosupply.com/Equus-Digital-Ford-Code-Reader/dp/B000EW0KHW Equus - Digital Ford Code Reader 3145.

It has a 3 digit LCD display so that you don’t have to count flashes or beeps.. Cost is $22-$36.

Order it at Walmart for a better price and free shipping

Write down the codes that the computer outputs since they will give you information on problems that are stored in the computer's memory

Cylinder balance test

If you have idle or IAC/IAB problems and the engine will not idle on its own without mechanically adjusting the base idle speed above 625-750 RPM, this test will fail with random cylinders pointed out every time it runs. The IAC/IAB must be capable of controlling the engine speed to run in the 1300-1500 RPM range. Playing with the base idle speed by adjusting it upwards will not work, the computer has to be able to control the engine speed using the IAC/IAB.

Warm the car's engine up to normal operating temperature. With the test jumper in test position, start the engine and let it stabilize. It should flash a 10 and then a 4 and maybe an 11. If no 11, then there are other codes that will be dumped.

Write down the codes that the computer outputs since they will give you information that the computer found when it is running. These are often different from the stored codes.

One of the first tests it does is to open the EGR all the way, this will cause the engine to stumble and almost die. If the engine dies here then you have EGR problems.

To start the cylinder balance test, briefly floor the accelerator past 2500 RPM and let off the accelerator. The engine will stabilize at about 1300-1450 RPM and the cut off the fuel injectors one at a time. The engine speed will drop briefly and the computer will turn the fuel injector for the cylinder under test back on. Then it starts the process for the next cylinder. When it has sequenced through all 8 injectors, it will flash 9 for everything OK, or the number of the failing cylinder such as 2 for cylinder #2. Quickly pressing the throttle again up to 2500 RPM’s will cause the test to re-run with smaller qualifying figures.

Do it a third time, and if the same cylinder shows up, the cylinder is weak and isn’t putting out power like it should. See the Chilton’s Shop manual for the complete test procedure

See View: https://www.youtube.com/watch?v=HDXrkKS4jTE

for a visual tour through the process. There is no voice narration so you have to listen carefully for the engine sounds. I posted the link for the benefit of Stangnet members who had questions about how to do a cylinder balance test. I do not own that video and I am not the creator.

Do a compression test on all the cylinders.

Take special note of any cylinder that shows up as weak in the cylinder balance test. Low compression on one of these cylinders rules out the injectors as being the most likely cause of the problem. Look at cylinders that fail the cylinder balance test but have good compression. These cylinders either have a bad injector, bad spark plug or spark plug wire. Move the wire and then the spark plug to another cylinder and run the cylinder balance test again. If it follows the moved wire or spark plug, you have found the problem. If the same cylinder fails the test again, the injector is bad. If different cylinders fail the cylinder balance test, you have ignition problems or wiring problems in the 10 pin black & white electrical connectors located by the EGR.

How to do a compression test:

Only use a compression tester with a screw in adapter for the spark plug hole. The other type leaks too much to get an accurate reading. Your local auto parts store may have a compression tester to rent/loan. If you do mechanic work on your own car on a regular basis, it would be a good tool to add to your collection.

With the engine warmed up, remove all spark plugs and prop the throttle wide open with a plastic screwdriver handle between the throttle butterfly and the throttle housing. Crank the engine until it the gage reading stops increasing. On a cold engine, it will be hard to tell what's good & what's not. Some of the recent posts have numbers ranging from 140-170 PSI. If the compression is low, squirt some oil in the cylinder and do it again – if it comes up, the rings are worn. There should be no more than 10% difference between cylinders. Use a blow down leak test (puts compressed air inside cylinders) on cylinders that have more than 10% difference.

I generally use a big screwdriver handle stuck in the TB between the butterfly and the TB to prop the throttle open. The plastic is soft enough that it won't damage anything and won't get sucked down the intake either.

A battery charger (not the trickle type) is a good thing to have if you haven't driven the car lately or if you have any doubts about the battery's health. Connect it up while you are cranking the engine and it will help keep the starter cranking at a consistent speed from the first cylinder tested to the last cylinder.

Here is the post from @jrichker I think you need.

-Cylinder balance test: use this to find dead or weak cylinders:

Revised 09-Sep-2017 Added reminder to write down the stored codes and engine running codes.

The computer has a cylinder balance test that helps locate cylinders with low power output. You’ll need to dump the codes out of the computer and make sure that you have the A/C off, clutch depressed to the floor and the transmission in neutral. Fail to do this and you can’t do the engine running dump codes test that allows you to do the cylinder balance test.

Here's the way to dump the computer codes with only a jumper wire or paper clip and the check engine light, or test light or voltmeter. I’ve used it for years, and it works great. You watch the flashing test lamp or Check Engine Light and count the flashes.

Be sure to turn off the A/C, have the clutch depressed to the floor, and put the transmission in neutral when dumping the codes. Fail to do this and you will generate a code 67 and not be able to dump the Engine Running codes.

Here's how to dump the computer codes with only a jumper wire or paper clip and the check engine light, or test light or voltmeter. I’ve used it for years, and it works great. You watch the flashing test lamp or Check Engine Light and count the flashes.

If your car is an 86-88 stang, you'll have to use the test lamp or voltmeter method. There is no functional check engine light on the 86-88's except possibly the Cali Mass Air cars.

The STI has a gray connector shell and a white/red wire. It comes from the same bundle of wires as the self test connector.

89 through 95 cars have a working Check Engine light. Watch it instead of using a test lamp.

The STI has a gray connector shell and a white/red wire. It comes from the same bundle of wires as the self test connector.

WARNING!!! There is a single dark brown connector with a black/orange wire. It is the 12 volt power to the under the hood light. Do not jumper it to the computer test connector. If you do, you will damage the computer.

What to expect:

You should get a code 11 (two single flashes in succession). This says that the computer's internal workings are OK, and that the wiring to put the computer into diagnostic mode is good. No code 11 and you have some wiring problems.

This is crucial: the same wire that provides the ground to dump the codes provides signal ground for the TPS, EGR, ACT and Map/Baro sensors. If it fails, you will have poor performance, economy and drivability problems

Some codes have different answers if the engine is running from the answers that it has when the engine isn't running. It helps a lot to know if you had the engine running when you ran the test.

Dumping the Engine Running codes: The procedure is the same, you dump the codes and then you start the engine with the test jumper in place. Be sure the A/C is off, clutch depressed to the floor and the transmission is in neutral. You'll get an 11, then a 4 and the engine will speed up to do the EGR test. After the engine speed decreases back to idle, it will dump the engine running codes.

Trouble codes are either 2 digit or 3 digit, there are no cars that use both 2 digit codes and 3 digit codes.

Your 86-88 5.0 won't have a working Check Engine Light, so you'll need a test light.

See AutoZone Part Number: 25886 , $10

Alternate methods:

For those who are intimidated by all the wires & connections, see Actron® for what a typical hand scanner looks like. Normal retail price is about $30 or so at AutoZone or Wal-Mart.

Or for a nicer scanner see www.midwayautosupply.com/Equus-Digital-Ford-Code-Reader/dp/B000EW0KHW Equus - Digital Ford Code Reader 3145.

It has a 3 digit LCD display so that you don’t have to count flashes or beeps.. Cost is $22-$36.

Order it at Walmart for a better price and free shipping

Write down the codes that the computer outputs since they will give you information on problems that are stored in the computer's memory

Cylinder balance test

If you have idle or IAC/IAB problems and the engine will not idle on its own without mechanically adjusting the base idle speed above 625-750 RPM, this test will fail with random cylinders pointed out every time it runs. The IAC/IAB must be capable of controlling the engine speed to run in the 1300-1500 RPM range. Playing with the base idle speed by adjusting it upwards will not work, the computer has to be able to control the engine speed using the IAC/IAB.

Warm the car's engine up to normal operating temperature. With the test jumper in test position, start the engine and let it stabilize. It should flash a 10 and then a 4 and maybe an 11. If no 11, then there are other codes that will be dumped.

Write down the codes that the computer outputs since they will give you information that the computer found when it is running. These are often different from the stored codes.

One of the first tests it does is to open the EGR all the way, this will cause the engine to stumble and almost die. If the engine dies here then you have EGR problems.

To start the cylinder balance test, briefly floor the accelerator past 2500 RPM and let off the accelerator. The engine will stabilize at about 1300-1450 RPM and the cut off the fuel injectors one at a time. The engine speed will drop briefly and the computer will turn the fuel injector for the cylinder under test back on. Then it starts the process for the next cylinder. When it has sequenced through all 8 injectors, it will flash 9 for everything OK, or the number of the failing cylinder such as 2 for cylinder #2. Quickly pressing the throttle again up to 2500 RPM’s will cause the test to re-run with smaller qualifying figures.

Do it a third time, and if the same cylinder shows up, the cylinder is weak and isn’t putting out power like it should. See the Chilton’s Shop manual for the complete test procedure

See View: https://www.youtube.com/watch?v=HDXrkKS4jTE

for a visual tour through the process. There is no voice narration so you have to listen carefully for the engine sounds. I posted the link for the benefit of Stangnet members who had questions about how to do a cylinder balance test. I do not own that video and I am not the creator.

Do a compression test on all the cylinders.

Take special note of any cylinder that shows up as weak in the cylinder balance test. Low compression on one of these cylinders rules out the injectors as being the most likely cause of the problem. Look at cylinders that fail the cylinder balance test but have good compression. These cylinders either have a bad injector, bad spark plug or spark plug wire. Move the wire and then the spark plug to another cylinder and run the cylinder balance test again. If it follows the moved wire or spark plug, you have found the problem. If the same cylinder fails the test again, the injector is bad. If different cylinders fail the cylinder balance test, you have ignition problems or wiring problems in the 10 pin black & white electrical connectors located by the EGR.

How to do a compression test:

Only use a compression tester with a screw in adapter for the spark plug hole. The other type leaks too much to get an accurate reading. Your local auto parts store may have a compression tester to rent/loan. If you do mechanic work on your own car on a regular basis, it would be a good tool to add to your collection.

With the engine warmed up, remove all spark plugs and prop the throttle wide open with a plastic screwdriver handle between the throttle butterfly and the throttle housing. Crank the engine until it the gage reading stops increasing. On a cold engine, it will be hard to tell what's good & what's not. Some of the recent posts have numbers ranging from 140-170 PSI. If the compression is low, squirt some oil in the cylinder and do it again – if it comes up, the rings are worn. There should be no more than 10% difference between cylinders. Use a blow down leak test (puts compressed air inside cylinders) on cylinders that have more than 10% difference.

I generally use a big screwdriver handle stuck in the TB between the butterfly and the TB to prop the throttle open. The plastic is soft enough that it won't damage anything and won't get sucked down the intake either.

A battery charger (not the trickle type) is a good thing to have if you haven't driven the car lately or if you have any doubts about the battery's health. Connect it up while you are cranking the engine and it will help keep the starter cranking at a consistent speed from the first cylinder tested to the last cylinder.

Exrace89GT

Member

I think your new flywheel and clutch are out of balance. Just because they are new do not mean they are right.

91GTstroked

15 Year Member

- Jun 14, 2007

- 429

- 236

- 63

I think your new flywheel and clutch are out of balance. Just because they are new do not mean they are right.

I agree. I'd lean towards something clutch related isn't right.

Especially if this problem only started after those parts were replaced.

Similar threads

Resolved

Vibration issues

- Replies

- 11

- Views

- 1K

- Replies

- 26

- Views

- 3K

- Replies

- 28

- Views

- 3K

Engine

Vibration

- Replies

- 22

- Views

- 2K

- Replies

- 1

- Views

- 1K