- Jan 28, 2015

- 16

- 5

- 13

Hi everyone,

I recently purchased an 88 hatch that had major issues. I pulled the motor and discovered that some idiot had had the car bored .030 over and installed the pistons completely upside down. No not reversed upside down the dds flat top pistons valve reliefs were down facing towards the exhaust side. I pulled the heads and discovered the number two piston had broke due to the valves slapping the piston. Long story short I had to bore it .040 over shave and deck the heads and have a valve job done. I now have the engine back together and in the car.

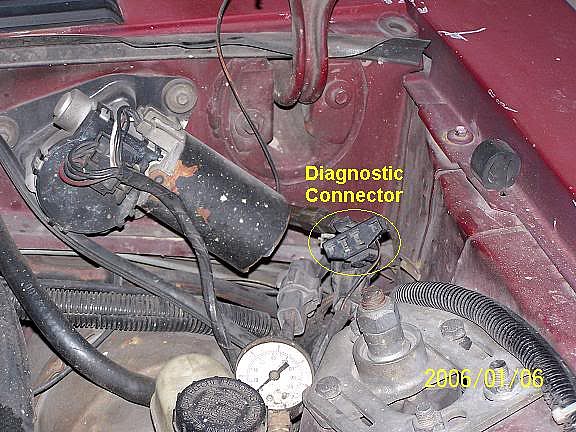

I went to start the car and noticed that the only way the fuel pump would prime is if I took the red/black wire from the fuel pump relay and jumped it to the pink/black wire. Obviously it runs continuously. I have tried jumping the grounds at the test jumper with the wires installed in the fuel pump relay correctly and still no power to the FP.

From here I replaced the fuel pump with a walbro 155, replaced the fuel pump relay, and replaced the EEC relay. Still no luck so from here I started digging into the wiring. Here is what I have so far.

EEC Relay: 12volts continuous on blk/orng wire always - working properly

red wire 12 volts ignition on 0volts ign off-working properly

blk/grn 12volts when tested from positive side of battery- this is the ground wire working properly

orng/blk to inertia switch 12volts ign on- working properly

Inertia Switch: Red wire 12volts-working properly

red/blk 12volts-working properly

Fuel pump relay: orng/lt blue 12 volts continuous always on- working properly

red/blk 12V ign on 0V ign off- working properly

pink/blk 0V ign on 0V ign off= not working I understand that the EEC gets its power from the EEC relay and when the ign initially comes on the EEC provides the ground to the FP relay and allows the circuit to close so that the FP kicks on 2-5 secs and then shuts off. And then as the PIP sensor signals to the EEC that the engine is running the EEC grounds (closes) the circuit and allows the fuel pump to work.

tan/lt grn tested this wire both jumped at the test connector and not jumped 1st Jumped: 0V ign off 1.2V ign on 2nd not jumped: 0V ign off 16mV ign on

I can get the car to run off of spraying starter fluid into the intake so I know it is getting proper spark.

I am getting 12 volts to my injectors however I conducted a pulse test by pluggin one end of my test light into the hot side and the other to the ground of the injector connector and trying to trick the EEC by turning the distributor and no pulse. I conducted this test on 3 different injectors on opposite sides of the intake with the same results. This is 1 thing that leads me to believe that it may be the EEC.

I then tested the TPS, MAF and EGR connectors with the ignition on. They are supposed to have 5Volts and they only had 2.3 Volts tested them multiple times with same results. this is 2nd thing that leads me to believe that it may be the computer.

I then moved to the EEC wiring harness tested pin 1 for constant power checked out good

tested pin 37/57 for power to injectors 12V ign on 0V ign off-working

tested pin 40/60 ground for EEC relay pin 40 6V ign on 0V ign off pin 60 10.5V ign on 0V ign off- not sure if this is correct.

tested pin 49 HEGO ground 6V ign on 0V ign off- again not sure

tested pin 46 test connector blk/whi wire ground crazy reading not jumped and jumped 12.5V ign on and crazy ign off- again not sure.

I believe that I have may have two problems: one with grounding at fuel pump relay and two I think the EEC is bad. However, the fuel pump relay gets its ground from the EEC.

The EEC relay is working because I have power to the EEC the injectors and the FP relay. I do not believe the EEC is closing the circuit for the FP to pump. The injectors have power but are not pulsing. The PIP sensor is working and sending signal to the EEC telling it that the engine is running but it seems like the EEC is not receiving this signal and relaying it to the injectors to pulse or closing the circuit for the FP.

Please help!!! Am I on the right track or should I test something else before purchasing a new EEC?

Thanks in advance.

I recently purchased an 88 hatch that had major issues. I pulled the motor and discovered that some idiot had had the car bored .030 over and installed the pistons completely upside down. No not reversed upside down the dds flat top pistons valve reliefs were down facing towards the exhaust side. I pulled the heads and discovered the number two piston had broke due to the valves slapping the piston. Long story short I had to bore it .040 over shave and deck the heads and have a valve job done. I now have the engine back together and in the car.

I went to start the car and noticed that the only way the fuel pump would prime is if I took the red/black wire from the fuel pump relay and jumped it to the pink/black wire. Obviously it runs continuously. I have tried jumping the grounds at the test jumper with the wires installed in the fuel pump relay correctly and still no power to the FP.

From here I replaced the fuel pump with a walbro 155, replaced the fuel pump relay, and replaced the EEC relay. Still no luck so from here I started digging into the wiring. Here is what I have so far.

EEC Relay: 12volts continuous on blk/orng wire always - working properly

red wire 12 volts ignition on 0volts ign off-working properly

blk/grn 12volts when tested from positive side of battery- this is the ground wire working properly

orng/blk to inertia switch 12volts ign on- working properly

Inertia Switch: Red wire 12volts-working properly

red/blk 12volts-working properly

Fuel pump relay: orng/lt blue 12 volts continuous always on- working properly

red/blk 12V ign on 0V ign off- working properly

pink/blk 0V ign on 0V ign off= not working I understand that the EEC gets its power from the EEC relay and when the ign initially comes on the EEC provides the ground to the FP relay and allows the circuit to close so that the FP kicks on 2-5 secs and then shuts off. And then as the PIP sensor signals to the EEC that the engine is running the EEC grounds (closes) the circuit and allows the fuel pump to work.

tan/lt grn tested this wire both jumped at the test connector and not jumped 1st Jumped: 0V ign off 1.2V ign on 2nd not jumped: 0V ign off 16mV ign on

I can get the car to run off of spraying starter fluid into the intake so I know it is getting proper spark.

I am getting 12 volts to my injectors however I conducted a pulse test by pluggin one end of my test light into the hot side and the other to the ground of the injector connector and trying to trick the EEC by turning the distributor and no pulse. I conducted this test on 3 different injectors on opposite sides of the intake with the same results. This is 1 thing that leads me to believe that it may be the EEC.

I then tested the TPS, MAF and EGR connectors with the ignition on. They are supposed to have 5Volts and they only had 2.3 Volts tested them multiple times with same results. this is 2nd thing that leads me to believe that it may be the computer.

I then moved to the EEC wiring harness tested pin 1 for constant power checked out good

tested pin 37/57 for power to injectors 12V ign on 0V ign off-working

tested pin 40/60 ground for EEC relay pin 40 6V ign on 0V ign off pin 60 10.5V ign on 0V ign off- not sure if this is correct.

tested pin 49 HEGO ground 6V ign on 0V ign off- again not sure

tested pin 46 test connector blk/whi wire ground crazy reading not jumped and jumped 12.5V ign on and crazy ign off- again not sure.

I believe that I have may have two problems: one with grounding at fuel pump relay and two I think the EEC is bad. However, the fuel pump relay gets its ground from the EEC.

The EEC relay is working because I have power to the EEC the injectors and the FP relay. I do not believe the EEC is closing the circuit for the FP to pump. The injectors have power but are not pulsing. The PIP sensor is working and sending signal to the EEC telling it that the engine is running but it seems like the EEC is not receiving this signal and relaying it to the injectors to pulse or closing the circuit for the FP.

Please help!!! Am I on the right track or should I test something else before purchasing a new EEC?

Thanks in advance.