You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

90 Mustang 5.0 motor mount stud spins

- Thread starter mechman81

- Start date

-

Sponsors (?)

Have you tried an air gun?

Yes, I've tried an impact gun and it just spins. Threads might be stripped too idk.

Try this, put a jack under the engine, use a 2x4 placed on the jack and the oil pan rail where the bolts are, put some pressure lifting that side of the engine, use the weight to put pressure on the nut and use a breaker bar, not the air gun, to force the nut to grab some good threads

@mechman81

It's nut splitter time....

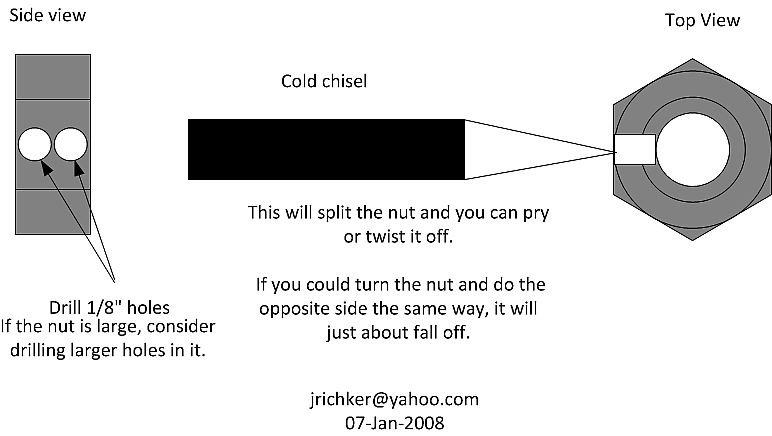

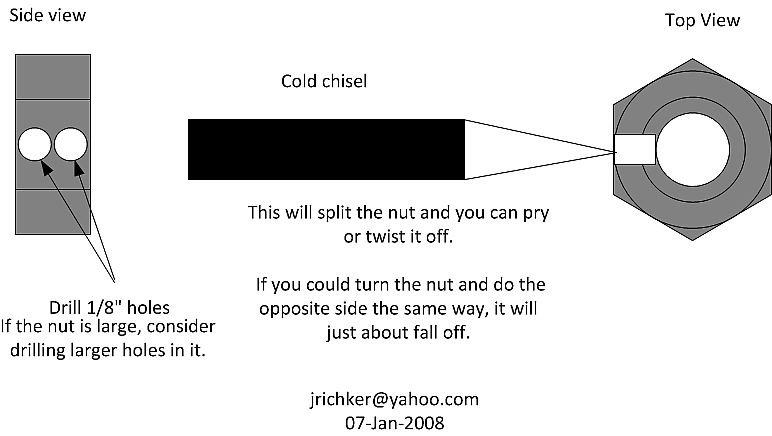

The holes should span just about the same area as shown in the drawing; 1/8" holes work good for 5/16" and 3/8" nuts. A motor mount nut might need a pair of 1/4" or 5/16" holes as shown it the drawing.

It's nut splitter time....

The holes should span just about the same area as shown in the drawing; 1/8" holes work good for 5/16" and 3/8" nuts. A motor mount nut might need a pair of 1/4" or 5/16" holes as shown it the drawing.

Attachments

Jrichker= refined, intelligent use of tools and skills when resolving issues.

General Karthief = backyard, knuckle busting use of tree limbs and stuff stolen from the neighbor that may cause injury or death and cost thousands in tax dollars to repair or replace.

Now who sounds like more fun at a party?

General Karthief = backyard, knuckle busting use of tree limbs and stuff stolen from the neighbor that may cause injury or death and cost thousands in tax dollars to repair or replace.

Now who sounds like more fun at a party?

Now who sounds like more fun at a party?

You sound like a real animal and I can respect that. The mount is doweled to the frame so lifting it won't put pressure on the nut.

@mechman81It's nut splitter time.

There's no way I can get a drill in there. Maybe a Dremel with extension and cutting disc?

Here's a novel idea.....I assume you're trying to pull the engine. ( I mean,....why else would you need to unbolt the stud?)

Why don't you unbolt the mount from the engine, and pull the motor, then you can get to the back side of the mount?

Why don't you unbolt the mount from the engine, and pull the motor, then you can get to the back side of the mount?

I don't wanna risk a torch damaging the frame and drilling it from the side is impossible with it being recessed. I thought of using a Dremel with long extension with a cutting disc on the end. I'll attempt this wednesday and let yall know. Appreciate the help.

Guys I'll also be replacing the clutch and I have a question about pilot bearings. Are you supposed to fill in the crank hole with bearing grease to keep the bearing lubed or do you just leave it dry with what's already prelubed into the bearing? And what could it hurt to do this? Will it somehow sling out onto the clutch disc overtime?

Last edited:

That subject came up in a recent gathering of stangnet members to thrash on a engine/trans install, yes I was there and may or may not have been helpful, one member said he just 'jams that thing in there', one said he 'puts a little extra in just because' and the third one said 'whats a pilot bearing?' (I wonder who that was)

So, what do others do?

So, what do others do?

- Mar 2, 2015

- 6,821

- 5,858

- 203

I put a little high temperature bearing grease in the pilot bearing. You don't want to use a lot because it can melt and get on the flywheel surface. If that happens it could ruin the clutch friction disc.

Fordfreak93

Mustang Master

Get a bigger impact and hammer down on that thing. Try and get a pry bar behind the mount to put pressure on the back of the bolt or use @General karthief idea and jack up or hoist the engine up a little to put pressure on it. I doubt the bolt is stripped, the rubber around it has broken and now it spins freely.

GOvert

15 Year Member

If you can't get the nut off your motor mount pull the transmission and grease your pilot bearing

Similar threads

- Replies

- 5

- Views

- 971

- Replies

- 4

- Views

- 986

- Replies

- 2

- Views

- 273

- Replies

- 3

- Views

- 808