You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AT Racing World heads? (Or other "cheap" brands...)

- Thread starter LILCBRA

- Start date

-

Sponsors (?)

I wish somebody would buy something like these cheaper aluminum heads . Or at least admit to it . I would like to try ther SVT heads from LMR. I bet they might be good . I cant do $1800 ,. to many other things. Im golng to the local machine shop that builds race engines and ask about porting my e-7 s with the Trickflow spring kit. I know its a bad idea but hat way I dont have to buy a bunch of extras.

I wish somebody would buy something like these cheaper aluminum heads . Or at least admit to it . I would like to try ther SVT heads from LMR. I bet they might be good . I cant do $1800 ,. to many other things. Im golng to the local machine shop that builds race engines and ask about porting my e-7 s with the Trickflow spring kit. I know its a bad idea but hat way I dont have to buy a bunch of extras.

Here is an option for you:

Flo-Tek 203505 Small Block Ford Aluminum Cylinder Head

You don't need to spend a fortune to get a top-performing, lightweight aluminum cylinder head for your small-block Ford V8. This Flo-Tek head has a long list of high-end features, minus the hefty price tag. Will likely need to plug the EGR connection holes in the end of these heads on 86-up...

These are what I am looking to get for my car unless a better deal presents itself in the meantime. I think it was actually Car Craft who tested them and found them to be comparable to the big names. They don't produce quite as well as the others, but they do hold their own and the price isn't all that bad.

Six Budget Ford Heads That Work - Car Craft Magazine - Hot Rod

We go hands on as we bolt-on six budget Ford heads onto our Ford Racing Boss 302 crate engine to see which is the best bang for your buck. The results might surprise you so see it for yourself in the February 2013 issue of Car Craft Magazine. six budget ford heads that work

Flo tech looks real good . Did you see the article on building a 300 hp 302 . Flo-tech was featured ,and many good things were said about them . I have a daughter thats in her senior year in college and Im down $100,000 I inherited some money and my wife wanted this . But I cant get money for heads . I should have , or wished I had grown some balls.

The ProMaxx heads are nice for the price. currently working with a guy doing a turbo build using the 190cc heads and a single 76/75 turbo on a 351w.. car makes stupid power.

Flo tech looks real good . Did you see the article on building a 300 hp 302 . Flo-tech was featured ,and many good things were said about them . I have a daughter thats in her senior year in college and Im down $100,000 I inherited some money and my wife wanted this . But I cant get money for heads . I should have , or wished I had grown some balls.

This article?:

Budget 350-Horse 302 Part 2: Speed Parts for Power

In Part 2 of our build, we take a machine shop–fresh 302 block and build it to into a solid, streetable performer without breaking the bank.

No, not until you said something about it and I searched for it. So far that's 2 magazine articles endorsing them that I've seen.

Vinnyb89

Member

I can shed some light on this (pro comps) I have done some research on these heads and watched some videos online to gather info as i was thinking of building a motor with them.

the sbc heads, the pushrod galleys were not aligned correctly so yes there was an issue of centering the rockers on the tip of the valve. What I have read was the sbf ones were okay. Next issue was port alignment. You will have to port match intake and exhaust gaskets and ports for everything to flow due to the cheap castings and you may have to play with different size gaskets to make it work with your application. then there is casting flaws, There's a cnc version or a non cnc. the non cnc they leave burs and extra material that can be removed from the ports to gain back the flow that they advertise. Next is spark plug depth has to be checked as some heads they were not deep enough into the bowl and required work, Along with that, there have been issues in the past that the valve jobs were not done very well and many people have had to redo them. Now some of these stories I came upon were from awhile ago 2011 era type times and from my research, they have come along way on most of these issues. Now moving on to the built heads there have been many reviews that they fall apart, valve guides wear, springs break and valves break off or even chip. So the best thing to do is research the make of what the heads are built with, there are many companies buying the castings then adding their own parts from cheap brands and that's why everyone suggests to just buy the casting and add your own parts.

My two cents... I bought a pair for experimental purposes from at racing world. 500$ cad with valves and springs to my door. They were better then i thought and it turns out the valves are qualfast/qualcast valves by part number once i took them apart to inspect them. I'm respringing due to the lift and seat pressures not being what i need. They will also need some of the work described in my top paragraph ( valves removed, ports cleaned up with Dremel, gasket matched ect) going to use the valves and guides with the heads and see what happens.

At the end of the day you get what you pay for but if you get them and throw in your own work they might be not bad. Some guy on youtube posted up a set he put on out of the box on his sbc and he ran them for 10 years on juice and they held together. Some people report they didn't make it out of the driveway. I can say i have yet to see a video on youtube about these heads that have failed, just forums of guys who have friends of friends..... due to this ive stated before in my other posts I will post my engine build and my dyno results and compare my new engine to my old engine

current engine: E7 heads with minor work, rmp airgap int, comp 268xe flat tappet with matching springs, 94 cobra rocker arms 1.7, timing chain, stock block/crank bored .30 over and on carb edelbrock 600. arp hardware.

vs: Pro comp heads, rpm airgap int, tf stage 2 track max cam with the matching springs (duals) 1.6 roller rockers, timing gear drive, stock block( roller), stock bore trw forged pistons and will be most likely be carbing up to 650 cfm. I will be running girdles on the top and bottom end with arp hardware for nitrous but i won't be using it for my dyno tests.

Now, In theory, many people have stated these heads are only for weight reductions and they are useless and flow like e7s I should have the same hp between both motors no matter what the bolt-ons are. So this is why im going to run the dyno tests. But in reality, since im increasing valve size and bigger ports changing cams and bigger carb I really don't see these two engines being close at all. Id like to think I could get60 hp na more than the e7 motor. Or maybe I make less ! who knows but im willing to try because this needs to be put to bed!

cheers!

Anthony.

the sbc heads, the pushrod galleys were not aligned correctly so yes there was an issue of centering the rockers on the tip of the valve. What I have read was the sbf ones were okay. Next issue was port alignment. You will have to port match intake and exhaust gaskets and ports for everything to flow due to the cheap castings and you may have to play with different size gaskets to make it work with your application. then there is casting flaws, There's a cnc version or a non cnc. the non cnc they leave burs and extra material that can be removed from the ports to gain back the flow that they advertise. Next is spark plug depth has to be checked as some heads they were not deep enough into the bowl and required work, Along with that, there have been issues in the past that the valve jobs were not done very well and many people have had to redo them. Now some of these stories I came upon were from awhile ago 2011 era type times and from my research, they have come along way on most of these issues. Now moving on to the built heads there have been many reviews that they fall apart, valve guides wear, springs break and valves break off or even chip. So the best thing to do is research the make of what the heads are built with, there are many companies buying the castings then adding their own parts from cheap brands and that's why everyone suggests to just buy the casting and add your own parts.

My two cents... I bought a pair for experimental purposes from at racing world. 500$ cad with valves and springs to my door. They were better then i thought and it turns out the valves are qualfast/qualcast valves by part number once i took them apart to inspect them. I'm respringing due to the lift and seat pressures not being what i need. They will also need some of the work described in my top paragraph ( valves removed, ports cleaned up with Dremel, gasket matched ect) going to use the valves and guides with the heads and see what happens.

At the end of the day you get what you pay for but if you get them and throw in your own work they might be not bad. Some guy on youtube posted up a set he put on out of the box on his sbc and he ran them for 10 years on juice and they held together. Some people report they didn't make it out of the driveway. I can say i have yet to see a video on youtube about these heads that have failed, just forums of guys who have friends of friends..... due to this ive stated before in my other posts I will post my engine build and my dyno results and compare my new engine to my old engine

current engine: E7 heads with minor work, rmp airgap int, comp 268xe flat tappet with matching springs, 94 cobra rocker arms 1.7, timing chain, stock block/crank bored .30 over and on carb edelbrock 600. arp hardware.

vs: Pro comp heads, rpm airgap int, tf stage 2 track max cam with the matching springs (duals) 1.6 roller rockers, timing gear drive, stock block( roller), stock bore trw forged pistons and will be most likely be carbing up to 650 cfm. I will be running girdles on the top and bottom end with arp hardware for nitrous but i won't be using it for my dyno tests.

Now, In theory, many people have stated these heads are only for weight reductions and they are useless and flow like e7s I should have the same hp between both motors no matter what the bolt-ons are. So this is why im going to run the dyno tests. But in reality, since im increasing valve size and bigger ports changing cams and bigger carb I really don't see these two engines being close at all. Id like to think I could get60 hp na more than the e7 motor. Or maybe I make less ! who knows but im willing to try because this needs to be put to bed!

cheers!

Anthony.

In some respects it sounds a lot like most of the knock off parts. The intake I bought and posted about had to have a little bit of port work too as they were off a little compared to the intake gaskets I was using. I think it works well with my engine and it was really hard to beat the price compared to an Eddy RPM Air Gap. That personal experience and the fact I found these heads for super cheap led me to ask about them. I'm probably a couple years away from actually doing anything with my convertible at this point, but if I would have bought them I would post up what I found with pics to back everything up. I mean not everyone can throw x amount of money into such and such brand name yet still come up with acceptable performance with a knock off brand at an amount they can more easily afford. So if you're building an engine with these or Pro Comps or anything else, I encourage a write up!

This may be an opportunity if anyone's interested. The bare heads are on Ebay now for $182.19/head through a different seller.

Electronics, Cars, Fashion, Collectibles & More | eBay

Buy & sell electronics, cars, clothes, collectibles & more on eBay, the world's online marketplace. Top brands, low prices & free shipping on many items.

rover.ebay.com

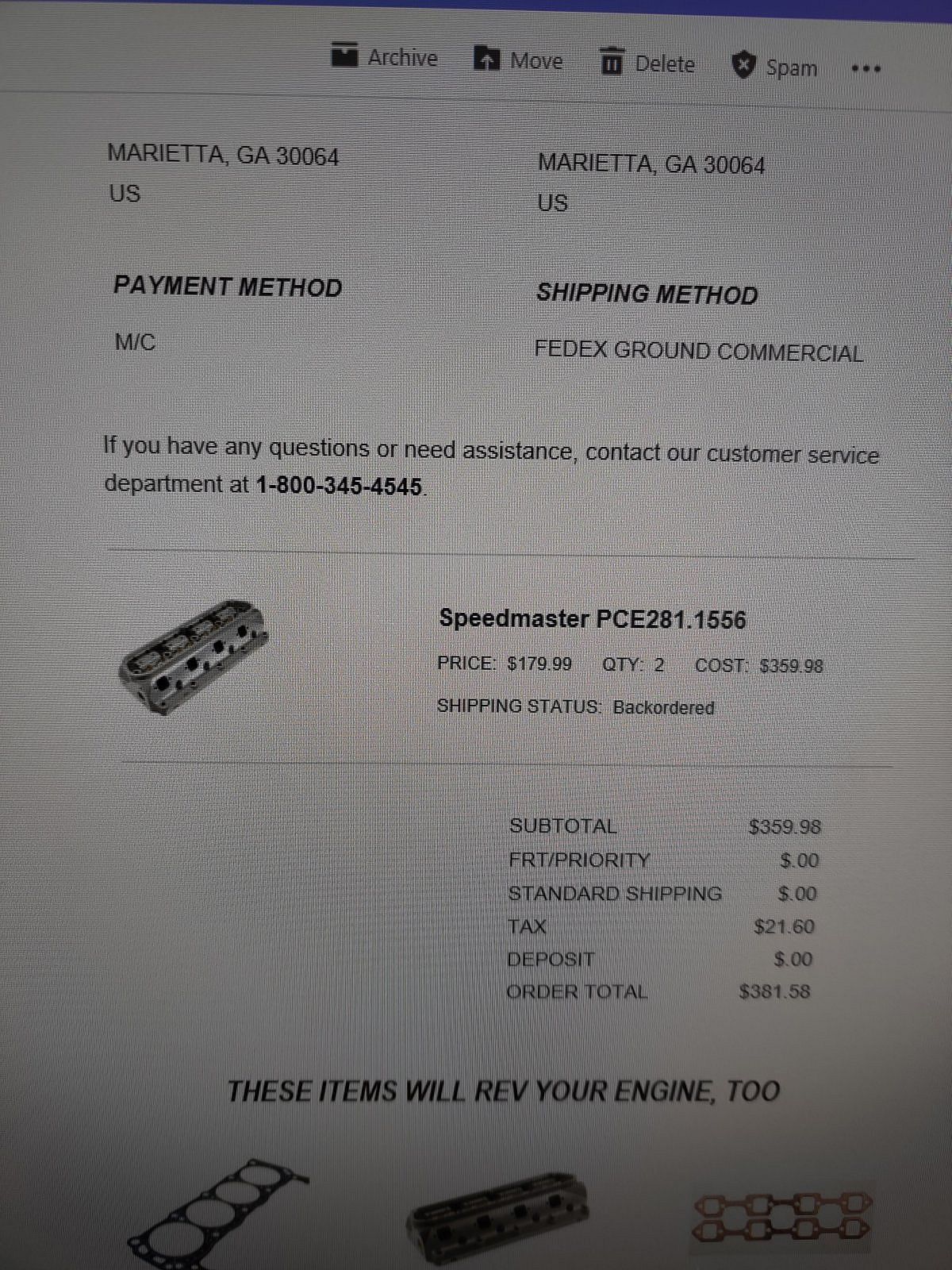

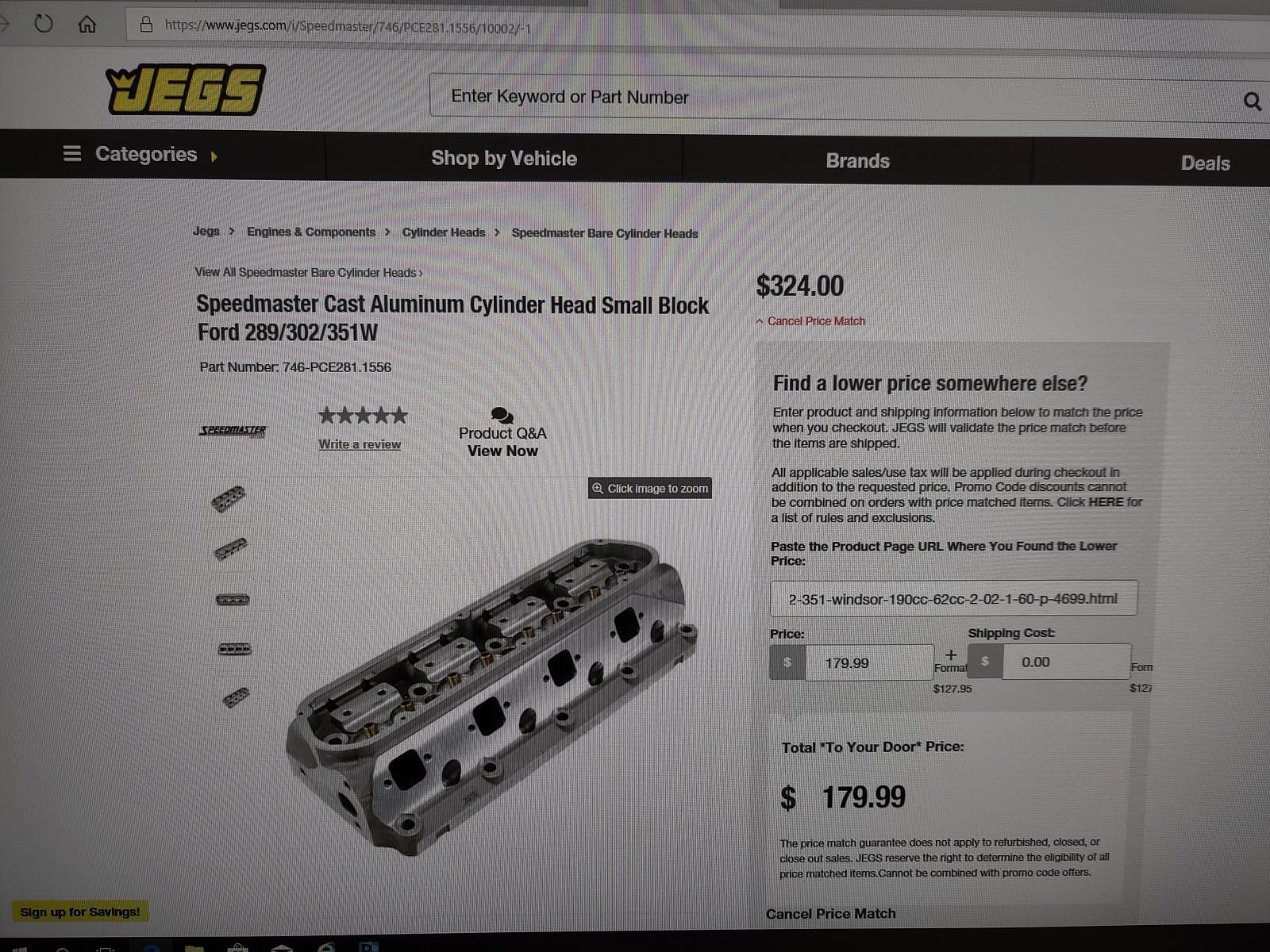

The Ebay listing I posted yesterday got me thinking about these again and snooping around the interwebz to see what I could find. Along with the link I posted earlier about connecting with the Chinese suppliers for the castings, I found a couple of Chinese sites that offer the bare castings for 179.99. Since I don't really trust them, I'm seriously contemplating trying either Summit's of Jeg's price match. I mean for $360, of course there's the added expenses of getting valvetrain - which may or may not had to happen anyway - I can't see how this would be a horrible idea. And again, as I said previously, it's like paying in installments.

Anyway, for anyone who might be interested, here's the web address if you think about trying to either buy from them directly or go the route I'm looking to try....

And a shot of the Jeg's price match screen:

Anyway, for anyone who might be interested, here's the web address if you think about trying to either buy from them directly or go the route I'm looking to try....

And a shot of the Jeg's price match screen:

Great its about time we get a review on some of this stuff. Nice to get a price on the machine shop. Somebody besides me sometime needs to do a Flotech set of heads. Thanks for the info.

Update on the Jeg's attempted purchase: they are denying the price match from the other website stating it's from a different manufacturer since the description lists it as an interchange part number. Back to square one.

jakeklein89

Active Member

Funny enough we have a 94 vert we just dropped a 393 winsor tko 600 trans and 9inch rear end into and the motor happens to have these heads. I do have to agree with the quote on “ seem to not make power “ we have a 393 with a comp cam believe the lift is .555 forged internals and an edlebrock intake set up that cost around $1400 its got 2 4 barrel carbs on top and it dynoed 415 hp and 454 torque at the flywheel we were instantly disappointed in the heads. They are the procomp 3037 185 heads. We barely have 500 miles on the build and my dad already plans to spend tax money on arf or an equivalent.... :/Working an extra shift overnight tonight and have more downtime, so I've searched for a bit more information about these heads. It appears that they are indeed the Pro Comp 3037 heads. Googling the FF part number gives a few sites that cross reference them both. I also ran into a thread on Corral from 2007 that the poster wasn't able to center the rockers on the valve tips. Who knows if this is still an issue. (That's a rhetorical statement....)

Pro Comp PC3037 Heads

I just acquired a pair of Pro Comp Pc3037 heads from a trade. Here are the specs: These heads feature a multi-angle seat design for performance valve springs. In addition, they have hardened seats and bronze valve guides. The advanced port design allows greater flow. This is the 190cc, angled...forums.corral.net

Among other websites, I also found this one. It looks like maybe it is from a middle man to connect you with the manufacturer? In any event, from what I gather from the site is you're able to get the bare castings for $1 if you order 5 or more. Who knows what shipping costs and all of that would add to it, but damn! That gets the wheels turning!!

But then I remembered about the dropped valve seat and searched to see if I could find that. Lo and behold it was right here on Stangnet!! So those turning wheels ended up coming to an abrupt halt. It's most likely better to stay the course with the projects I have going on right now vs spending money on these then turning around and spending more money on them to make them work reliably. I have a feeling that by time it was all said and done I'd have just as much money in them as I would if I'd invested in some Trick Flows or Edelbrocks.

ProComp Head problems?

Hey i know its been a long time since i was on, so hey everyone. i had other interests occuping my time. any way i have seen the error of my ways and come back to the car! so here is the issue at hand, i am soon to return to the states and my projects and once again have been considering my...www.stangnet.com

Yeah, sounds like the heads are definitely the weak link in that build. A better flowing head should yield a much better outcome. I don't think the flow is there for that size of an engine whereas they may be acceptable for a standard bore and stroke 302 if you're not looking to squeeze every bit of power out of it that you can. If we were talking old school, I'd say you would probably do fairly well building a Clevor style engine. I would really like to do that, always wanted to do a 351W based 427 with Cleveland style heads. I believe there was a magazine article a while back that someone had done the same and pushed like 600hp or something? I don't remember, but it would be cool. I'll have to see if I can find it and share the link. The downside for your build is you would need to invest in a new intake and I don't think they make a 2x4 intake, but I could be wrong.

That didn't take long!! lol

www.hotrod.com

www.hotrod.com

How to Build a 750hp Ford “Clevor,” the Engine Masters way. - Hot Rod Network

Scott Main and team MPG Heads brought a 404-inch, Cleveland-headed, small-block Ford to do battle… Read More

Update on the Jeg's attempted purchase: they are denying the price match from the other website stating it's from a different manufacturer since the description lists it as an interchange part number. Back to square one.

Thanks for all the info, I was just about to purchase a set of FloTechs, 203-505. Although with all your and other folks info, my "low to no budget" cant afford part failure cost.

I'm (once again) beginning an old project, '67, stock, 289, coupe project. I just want a driver with above stock performance that will last.

You folks helped lots with all your input . . . Thank You. Slightly updated stock heads with minor Dremel work will do the trick.

. . . By the way, if you guys know of any places local to Los Angeles area, trust worthy services I would love any tips, or recommendations.

Tranny, heads, power steering rebuild work, and perhaps rear end work. Yeah, it's a boatload, babysteps. I'm trying to get the car back on the road with the help of my 15 year old. Father Son time.

Thanks again, and keep posting !

I came across this thread and felt I needed to give my personal experience. I'm a mopar guy but don't hold that against me, we're all car enthusiasts after all lol.

Pro comp/Speedmaster are an Australian based company, but not one thing in their catalog is manufactured here. Everything is made in China. Their reputation here is a joke. It got so bad at one point that the local car magazines stopped publishing their adds because of backlash from thsir angry customers. Their after sales assistance is also nonexistent.

That being said, back to the heads.

I bought a set of procomp heads for a mopar small block a few years ago. I bought them through ebay and because they had a promo going at the time I got the complete units with valves, springs etc. I had no intention of using any of the included gear but thought it would be a good starting point for measuring valve lengths and what not. When they turned up the intake valves were .120" longer than the exhaust valves. The spring pockets also had a difference of .050" between the 2 heads. The spring locators were also way too small for the pockets allowing the spring to dance around. It was as if they just dumped whatever they had on the bench in these heads and sent it out the door. I could only imagine what would have happen if someone pulled them out of the box and used them as is. What was worse was when I contacted them about it they tried to convince me that the valve lengths were fine and I had to use 2 different length sets of pushrods. Anyone who knows mopar small blocks knows that won't work without ending in tears. The quality in the casting of the heads are great. All the threaded holes have been helicoiled, so that's nice. I did do some port matching but you would probably want to check and do that anyway. All in all they're not too bad.

If you're going to buy them, get them bare, measure everything and order decent gear and I think you'll be pretty happy with them. I'd be willing to bet all the cheap heads are coming out of the same Chinese factory anyway so unless your budget can stretch to one of the reputable brands you'll be getting the same thing anyway.

Just my 2 cents. Cheers and good luck with your build.

Pro comp/Speedmaster are an Australian based company, but not one thing in their catalog is manufactured here. Everything is made in China. Their reputation here is a joke. It got so bad at one point that the local car magazines stopped publishing their adds because of backlash from thsir angry customers. Their after sales assistance is also nonexistent.

That being said, back to the heads.

I bought a set of procomp heads for a mopar small block a few years ago. I bought them through ebay and because they had a promo going at the time I got the complete units with valves, springs etc. I had no intention of using any of the included gear but thought it would be a good starting point for measuring valve lengths and what not. When they turned up the intake valves were .120" longer than the exhaust valves. The spring pockets also had a difference of .050" between the 2 heads. The spring locators were also way too small for the pockets allowing the spring to dance around. It was as if they just dumped whatever they had on the bench in these heads and sent it out the door. I could only imagine what would have happen if someone pulled them out of the box and used them as is. What was worse was when I contacted them about it they tried to convince me that the valve lengths were fine and I had to use 2 different length sets of pushrods. Anyone who knows mopar small blocks knows that won't work without ending in tears. The quality in the casting of the heads are great. All the threaded holes have been helicoiled, so that's nice. I did do some port matching but you would probably want to check and do that anyway. All in all they're not too bad.

If you're going to buy them, get them bare, measure everything and order decent gear and I think you'll be pretty happy with them. I'd be willing to bet all the cheap heads are coming out of the same Chinese factory anyway so unless your budget can stretch to one of the reputable brands you'll be getting the same thing anyway.

Just my 2 cents. Cheers and good luck with your build.

mustangman6579

Member

So sadly I had to make a new account. I guess if you don't use it for years, it gets deleted

Anyhow. I'm digging up an old thread as I just ordered these heads. I'm going to see just how much 'out of the box' I can run them.

Right now I have a mildly built 302 with ported E7s. I'm looking to get a few more ponies, and hope this would help.

My goal is to maybe hit near 350, but that might be a bit much if these heads are as bad as I am reading in here.

Anyhow. I'm digging up an old thread as I just ordered these heads. I'm going to see just how much 'out of the box' I can run them.

Right now I have a mildly built 302 with ported E7s. I'm looking to get a few more ponies, and hope this would help.

My goal is to maybe hit near 350, but that might be a bit much if these heads are as bad as I am reading in here.